Powder material airless packaging device

A powder material, airless technology, applied in packaging, solid materials, transportation and packaging, etc., can solve the problems that the powder material cannot be filled in the packaging bag at one time, the packaging bag produces flatulence, and the gas enters the packaging bag, etc., to achieve Eliminate flatulence, ensure packaging weight, and avoid the effect of material adsorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

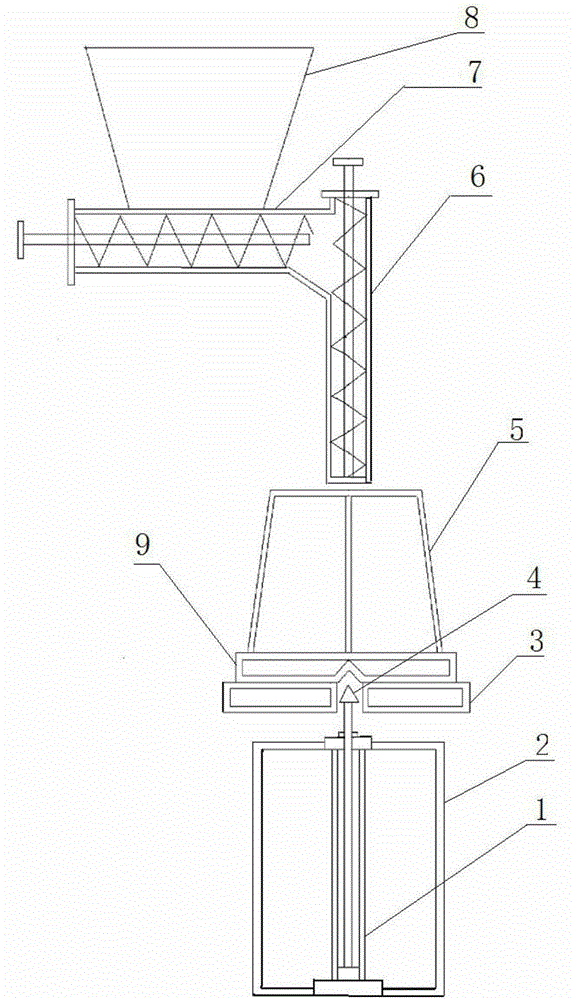

[0015] The device for airless packaging of powder materials of the present invention will be further described below in conjunction with the accompanying drawings:

[0016] The hollow packaging bag support 5 is placed directly above the electronic scale 3, and the center of the lower part of the base 9 has a tapered hole; the center of the electronic scale has a through hole for the cylinder shaft 4 to pass through; Bag support 5 coaxial cylinder 1, the top of the cylinder shaft 4 in the cylinder 1 is a positive cone;

[0017] There is a feeding screw 6 above the packaging bag support 5, and a feeding screw 7 is arranged below the hopper 8, and the feeding screw 7 is vertically connected with the feeding screw 6;

[0018] Feeding screw 6, packaging bag support 5 and cylinder shaft 4 are on the same axis.

[0019] The packaging bag support is a truncated cone with a small top and a large bottom.

[0020] The tapered hole at the center of the lower part of the base matches the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com