Automatic felt rolling mechanism used for high-speed mineral cotton felt rolling

A cotton rolling felt and rolling felt technology, which is applied in the field of automatic rolling felt mechanism, can solve the problems of large differences in product specifications, sizes and densities, low efficiency, poor working environment, etc., and achieves good product uniformity. Felt efficient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to better understand the present invention, the content of the present invention is further illustrated below in conjunction with the examples, but the content of the present invention is not limited to the following examples.

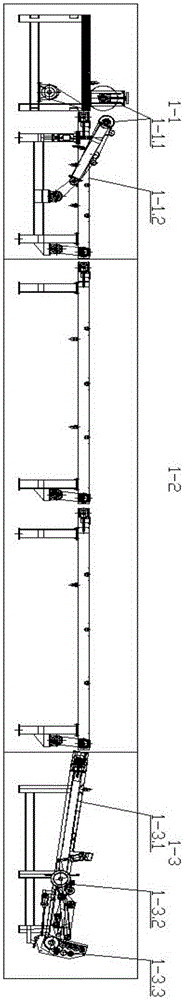

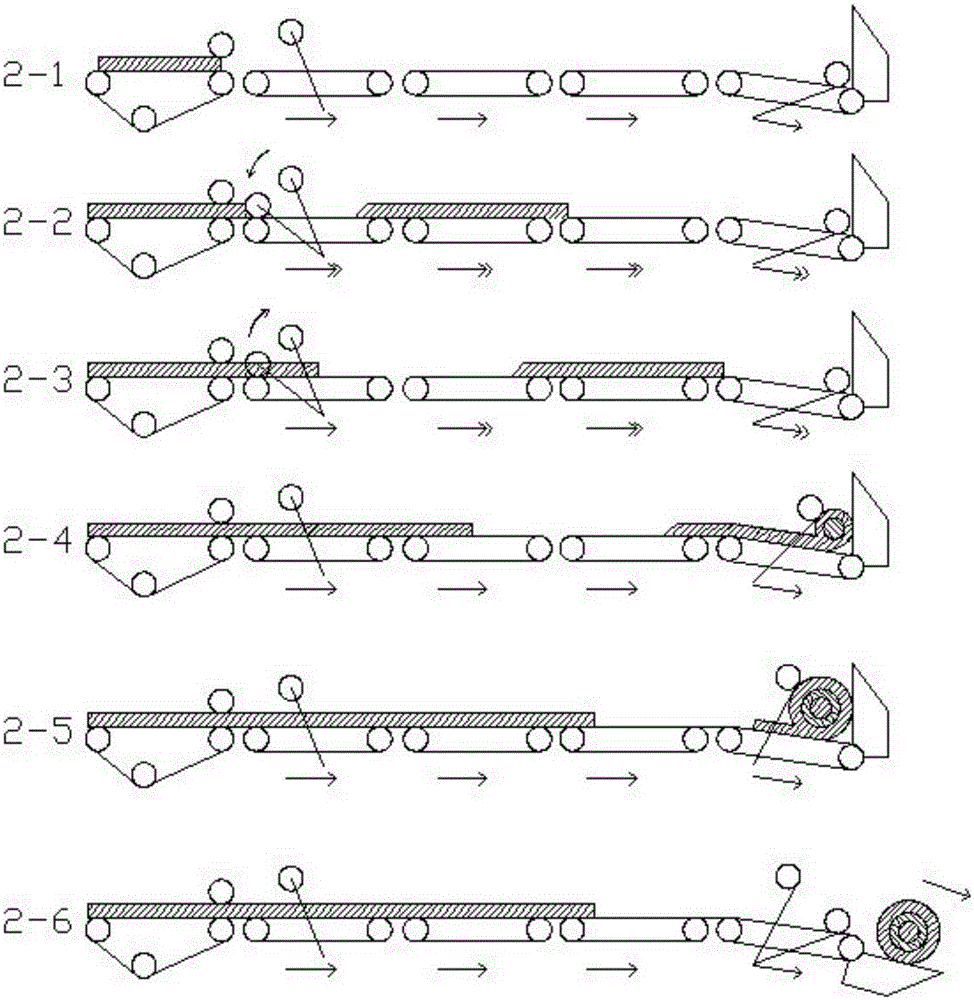

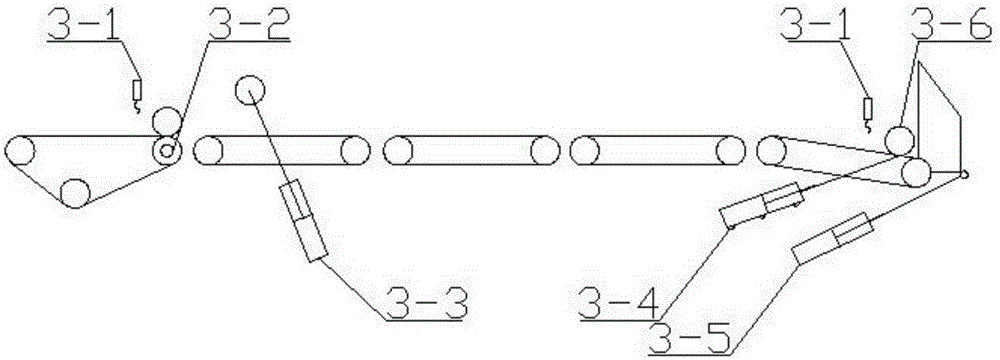

[0026] like figure 1 The shown automatic felt roll mechanism for high-speed mineral wool roll felt includes a cotton tearing unit, an acceleration unit, and a felt rolling unit that are connected in sequence; the cotton tearing unit includes a cotton tearing roller and a first belt conveyor, wherein , the tearing roller is located directly above the starting end of the first belt conveyor, and the end of the first belt conveyor is connected to the acceleration unit; the acceleration unit includes two speed-regulating belt conveyors connected in front and back; the felt rolling unit It includes a second belt conveying device, a mat rolling pressing roller device and a felt rolling guide roller device connected in sequence, wherein the se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com