A mems structure and manufacturing method thereof

A production method and technology for bonding materials, which are applied in microstructure technology, microstructure devices, manufacturing microstructure devices, etc., can solve problems such as very high process capability requirements, affecting product yield, etc., and achieve low process capability requirements and finished products. The effect of high rate and reliable fixing method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

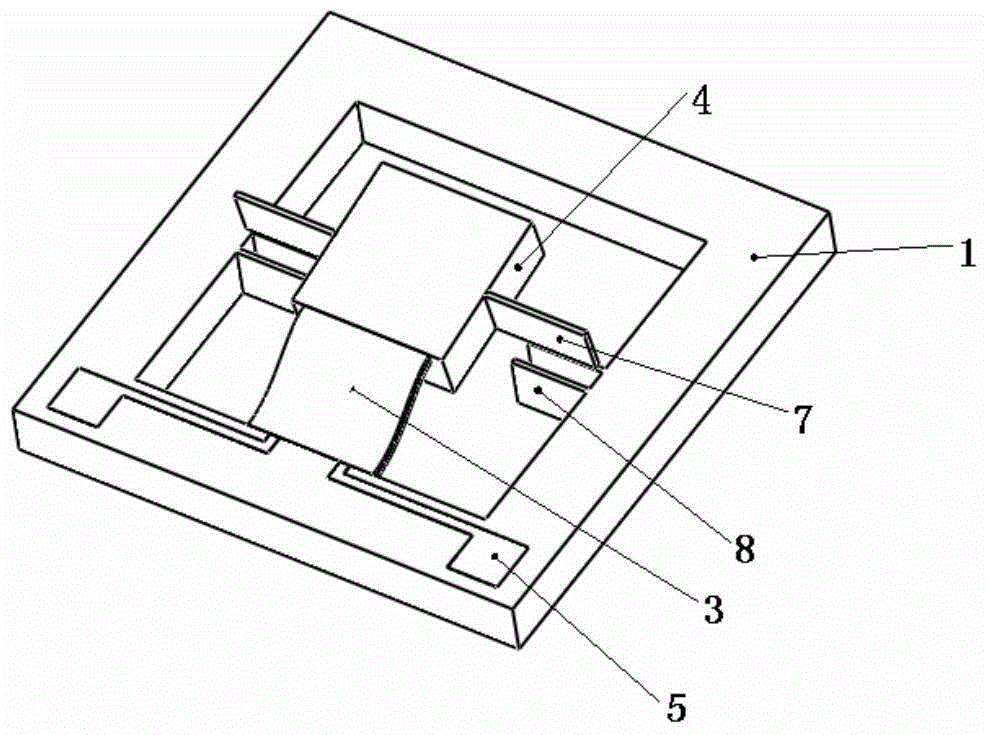

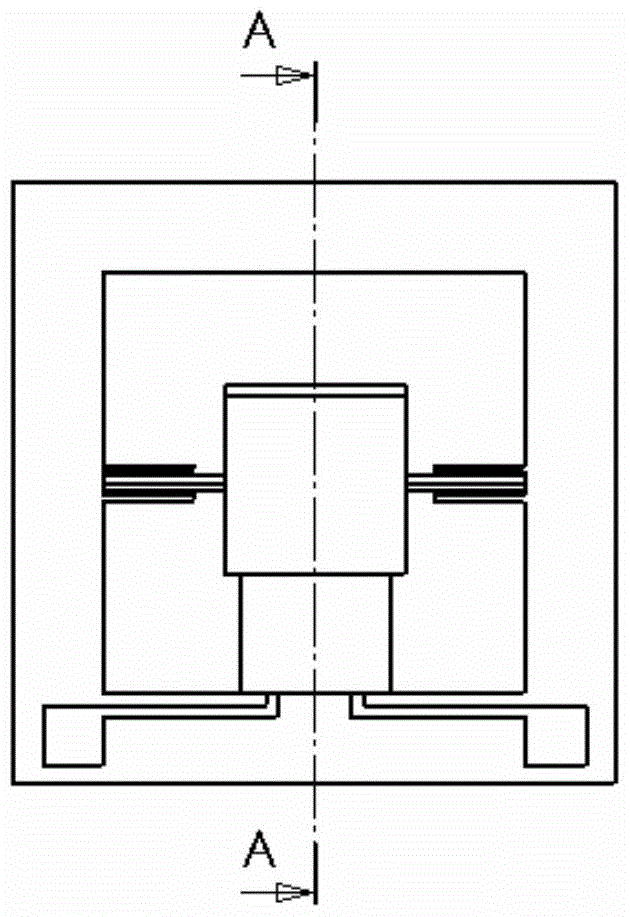

[0048] Such as figure 1 As shown, a MEMS structure includes a substrate 1, a suspended component 4, such as a mass or a mirror, and a controllable deformation component 3, wherein one end of the controllable deformation component 3 is connected to the substrate 1 , the other end is connected to the suspended component 4; a first connecting portion 7 is provided on the side of the suspended component 4; one end of the first connecting portion 7 is fixedly connected to the suspended component 4, and the other end is suspended. A second connection part 8 is provided on the substrate 1, and the second connection part 8 forms a matching relationship with the first connection part 7; the application of this structure can be applied to fields such as micro-optical light path adjustment and optical communication.

[0049] The substrate 1 provides a support for the MEMS structure of the present invention;

[0050] The first connecting portion 7 and the second connecting portion 8 are us...

Embodiment 2

[0070] The main difference between this embodiment and embodiment 1 is that the symmetrically distributed controllable deformation component 3 is used; the controllable deformation component 3 is made of Cu and W materials with different expansion coefficients;

[0071] Such as Figure 10 As shown, a MEMS structure includes a substrate 1, a suspended component 4 (such as a mass or a mirror), two symmetrically distributed controllable deformation components 3, one end of the controllable deformation component 3 is connected to the The substrate 1 is connected, and the other end is connected to the suspended component 4; a first connecting portion 7 is provided on the side of the suspended component 4; one end of the first connecting portion 7 is fixedly connected to the suspended component 4, and the other end dangling. A second connection part 8 is provided on the substrate 1, and the second connection part 8 forms a matching relationship with the first connection part 7; the...

Embodiment 3

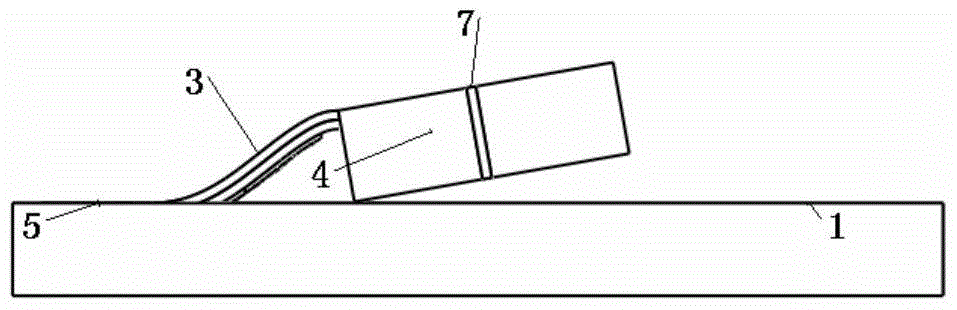

[0089] The main difference between this embodiment and embodiment 1 is that the controllable deformation part 3 is made of Au, SiO 2 Two kinds of materials with different expansion coefficients are compounded, and its effect is to lift the suspended part 4 above the surface of the substrate 1; and there is no electric lead 5; what the bonding material 6 uses is epoxy resin glue.

[0090] Such as Figure 9 As shown, a MEMS structure includes a substrate, a suspended part (mass or mirror), and a single controllable deformation part, wherein one end of the controllable deformation part is connected to the substrate, and the other end is connected to the suspended part. The suspension part is connected; a first connection part 7 is provided on the side of the suspended part; one end of the first connection part 7 is fixedly connected with the suspended part, and the other end is suspended. The application of the structure can be applied to the fields of micro-optical light path a...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap