Electro-Fenton source sludge reduction method and system based on electrochemical sludge pretreatment

A pretreatment and electrochemical technology, applied in sludge treatment, chemical instruments and methods, water/sludge/sewage treatment, etc., can solve problems affecting the subsequent utilization of sludge, complicated system regulation process, and toxic effects of by-products , to achieve the effects of saving the cost of chemicals, improving reaction efficiency and promoting electro-oxidation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

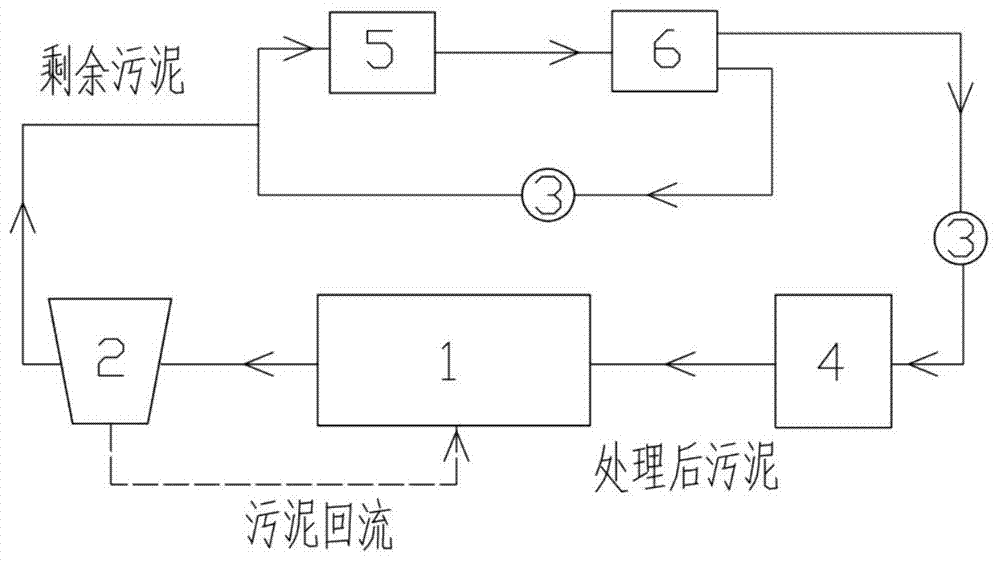

[0025] Embodiment 1: a kind of electro-Fenton source sludge reduction method based on electrochemical sludge pretreatment of the present invention comprises the following steps:

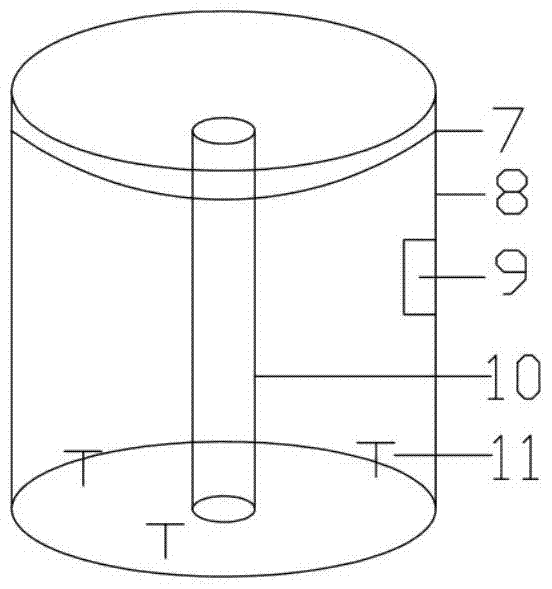

[0026] (1) Electrolytic pretreatment of excess sludge: After the excess sludge with a solid content of 3%-5% enters the reactor, a pre-electrolytic reaction is carried out. When the pH value and temperature conditions meet the requirements of electro-Fenton treatment, it starts to run one step;

[0027] (2) Electro-Fenton oxidation treatment of sludge: After the pH value and temperature conditions of the electrolytically pretreated sludge meet the requirements of electro-Fenton treatment, the aeration equipment near the cathode at the bottom of the reactor starts to aerate and injects air into the reactor. Put in iron powder;

[0028] (3) Sludge pH adjustment: add Ca(OH) with a concentration of 5% to the sludge after electro-Fenton oxidation treatment 2 The solution adjusts the pH of the sludge to ...

Embodiment 2

[0037] Embodiment 2: The difference between this example and Example 1 is: electrolytic pretreatment of residual sludge in the step (1) in the electro-Fenton source sludge reduction method based on electrochemical sludge pretreatment: voltage The gradient is 6V / cm, and the pretreatment time is 30min.

[0038] In the step (2), the pH of the electro-Fenton oxidation treatment of the sludge is controlled at 3, and the ratio of the dry weight of iron powder to the sludge to the reactor is 0.005.

[0039] The (3) step sludge pH value adjustment: add Ca(OH) with a concentration of 5% to the sludge after electro-Fenton oxidation treatment 2 The solution adjusts the pH of the sludge to 7, Ca(OH) 2 The ratio of dosage to sludge dry weight is 0.05.

Embodiment 3

[0040] Embodiment 3: The difference between this example and Example 1 is: electrolytic pretreatment of residual sludge in the step (1) in the electro-Fenton source sludge reduction method based on electrochemical sludge pretreatment: voltage The gradient is 2V / cm, and the pretreatment time is 20min.

[0041] In the step (2), the pH of the electro-Fenton oxidation treatment of the sludge is controlled at 2, and the ratio of the dry weight of the iron powder to the sludge to the reactor is 0.005.

[0042] The (3) step sludge pH value adjustment: add Ca(OH) with a concentration of 5% to the sludge after electro-Fenton oxidation treatment 2 The solution adjusts the pH of the sludge to 7, Ca(OH) 2 The ratio of dosage to sludge dry weight is 0.03.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com