Preparation method of phenolic resin type surfactant and prepared phenolic foam plastic

A technology of phenolic foam plastics and surfactants, applied in the field of phenolic foam plastics, can solve problems affecting water absorption, thermal conductivity and strength, and the stability of foam closed cells, forming foams, etc., to achieve low water absorption, stable structure, The effect of low thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

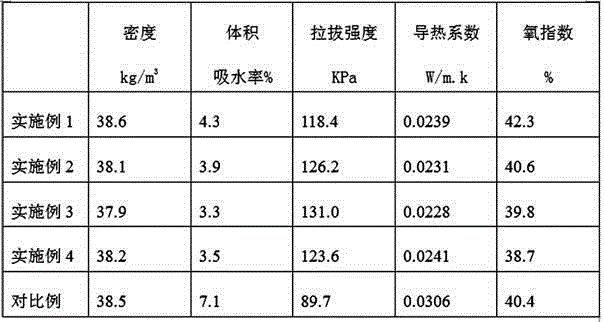

Examples

Embodiment 1

[0065] Each raw material proportioning by weight of described phenolic resin type surfactant is as follows:

[0066] 30 parts of alkylphenol

[0067] 70 parts of phenol

[0068] Paraformaldehyde 42 parts

[0069] 1 part of 30% sodium hydroxide solution;

[0070] urea 5 parts

[0071] 4 parts water

[0072] Preparation process: Mix 300g of nonylphenol and 210g of phenol into the reactor, add 210g of paraformaldehyde and 40g of water, stir evenly, adjust the pH to 8.0 with 30% sodium hydroxide solution, and raise the temperature to 78~ Pre-polymerize alkylphenols and aldehydes at a constant temperature of 82°C for 40 minutes, then add the remaining 490g of phenol and 210g of paraformaldehyde and continue to heat up to 90°C until the viscosity reaches 9000±1000cp. Prepared phenolic resin type surfactant.

[0073] Prepare phenolic foam plastics with above-mentioned phenolic resin type surfactant, raw material proportioning is as follows by weight;

[0074] 90 parts of conve...

Embodiment 2

[0080] Raw material and preparation method identical proportioning with embodiment 1 prepare phenolic resin type surfactant;

[0081] Phenolic foam plastics are prepared according to the following proportions by weight of raw materials:

[0082] Conventional phenolic resin 80 parts

[0083] 20 parts of phenolic resin type surfactant

[0084] Foaming agent 6.3 parts

[0085] Curing agent 17 parts

[0086] Described foam preparation process is identical with embodiment 1; Increased the consumption of described phenolic resin type surfactant in the weight ratio, because the molecular weight of phenolic resin type surfactant is bigger, so the active group of unit weight is relatively conventional phenolic resin With less resin, the required curing dosage is correspondingly reduced; when the dosage of phenolic resin type surfactant increases, the viscosity of the system increases accordingly, so the dosage of foaming agent needs to be increased correspondingly to meet the foamin...

Embodiment 3

[0088] Raw material and preparation method identical proportioning with embodiment 1 prepare phenolic resin type surfactant;

[0089] Phenolic foam plastics are prepared according to the following proportions by weight of raw materials:

[0090] Conventional phenolic resin 75 parts

[0091] 25 parts of phenolic resin type surfactant

[0092] Foaming agent 6.8 parts

[0093] Curing agent 16 parts

[0094] The preparation process of the phenolic foam plastic is the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com