Vertical spraying solid-solution quenching machine train for high-strength aluminium alloy sheets

A vertical spraying and solid solution quenching technology, applied in quenching devices, heat treatment equipment, manufacturing tools, etc., can solve the problems of difficult control of plate shape, high production cost, general efficiency, etc., and achieve flexible operation and low production cost , fast heating effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

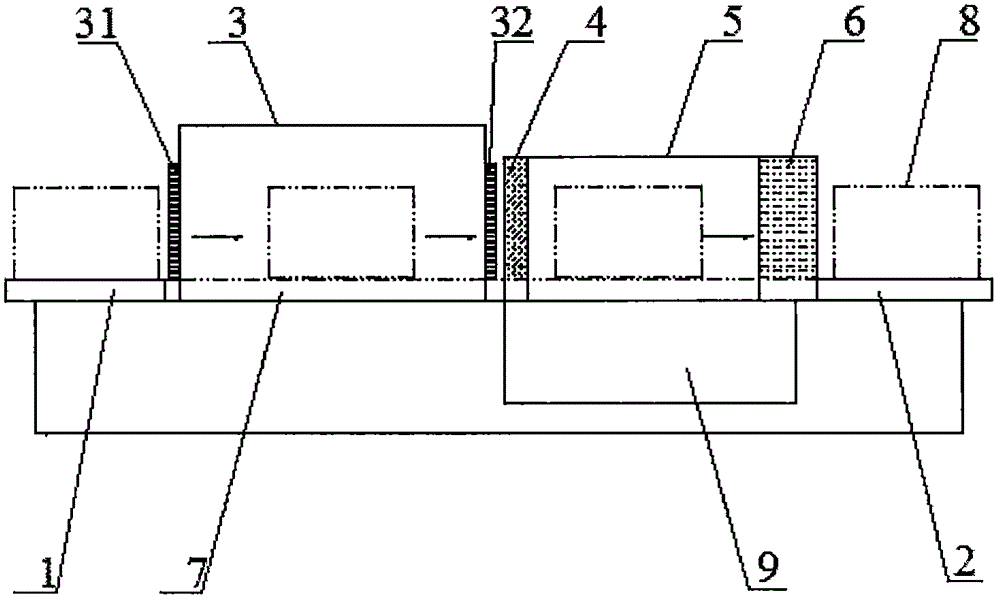

[0028] Embodiment 1: In the implementation process, the size of the feeding platform 1 is 8000mm × 1600mm, and there are two tracks on the transmission track platform 7, the track spacing is 1200mm, and the tracks extend to the furnace door of the solid solution heating furnace body 3, and are connected to the bottom of the furnace door and The tracks in the furnace meet.

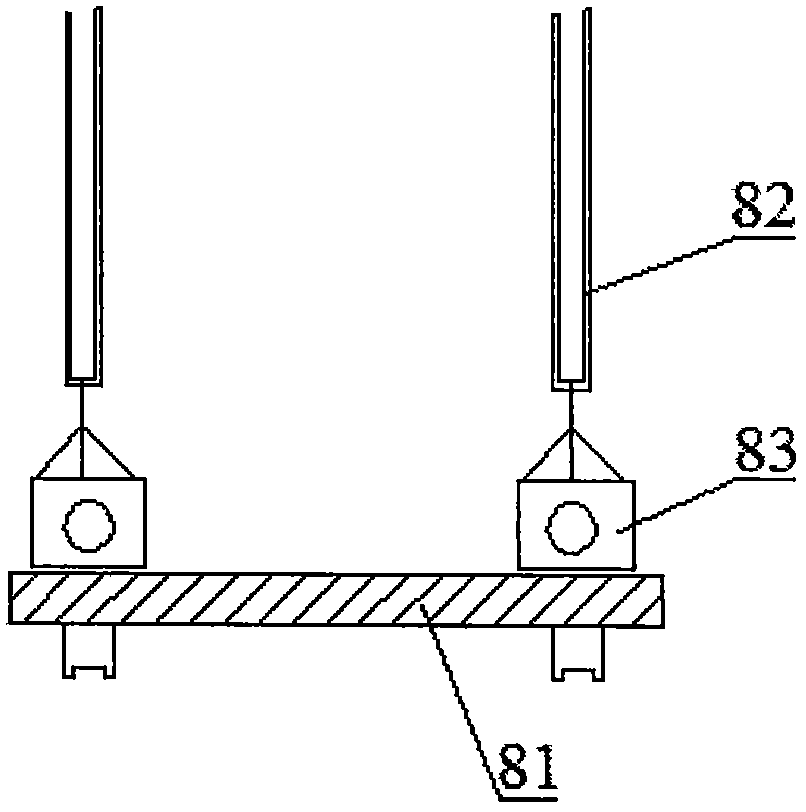

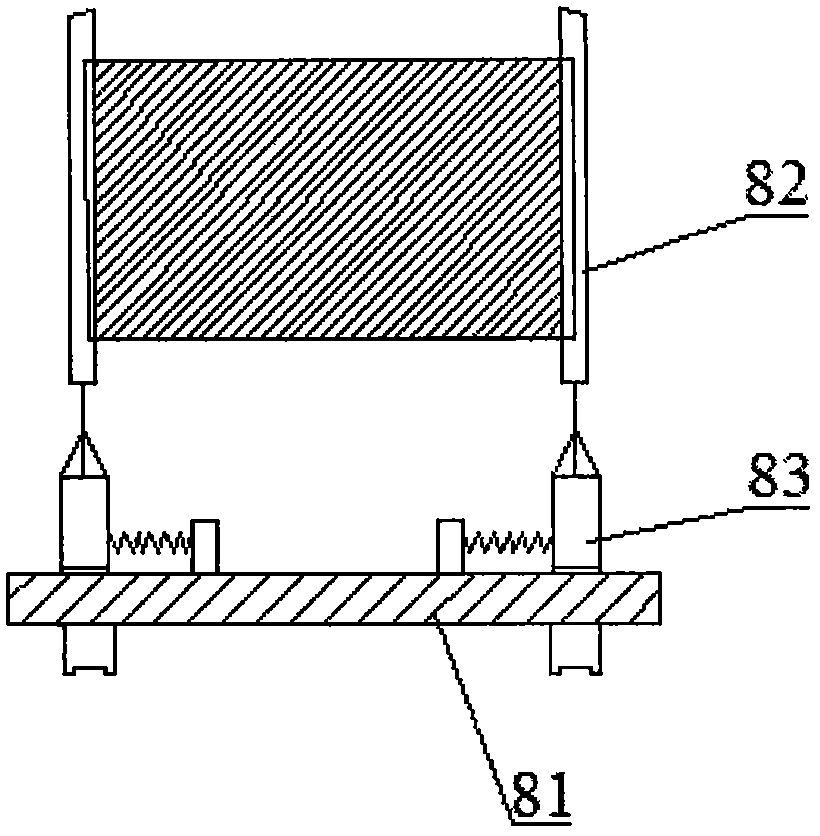

[0029] A special fixture 8 with a specification of 6000mm×1500mm is adopted, and a total of six 7075 aluminum alloy sheets with a specification of 6000mm×1250mm×10mm are installed on the special fixture 8. There is an elastic clamp 82 and an elastic tensioning device 83 on the special fixture 8 In the cold state, use the elastic tensioning device 83 to apply a tension of about 300kg along the length of the sheet, and the elastic tensioning device reserves 70mm of expansion and contraction; open the entrance furnace door 31 of the solid solution heating furnace body 3, and the special The fixture 8 is drawn ...

Embodiment 2

[0033] Embodiment 2: In the implementation process, the size of the feeding platform 1 is 8000mm × 1600mm, and there are two tracks on the transmission track platform 7, the track spacing is 1200mm, and the tracks extend to the solid solution heating furnace body 3 furnace door, and under the furnace door and The tracks in the furnace meet.

[0034] Using a special fixture 8 with a specification of 6000mm×1500mm, six 7075 aluminum alloy sheets with a specification of 6000mm×1250mm×1mm are installed on the special fixture 8, and there is an elastic clamp 82 and an elastic tensioning device 83 on the special fixture 8 In the cold state, use the elastic tensioning device 83 to apply a tension of about 150kg along the length of the sheet, and the elastic tensioning device reserves 70mm of expansion and contraction; open the entrance furnace door 31 of the solid solution heating furnace body 3, and the special The fixture 8 is drawn into the heating furnace along the track.

[003...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com