Seed cotton foreign fiber treatment system

A foreign fiber and processing system technology, applied in fiber processing, mechanical processing, textiles and papermaking, etc., can solve the problems of cotton layer cannot be cleaned, long cleaning time, low cleaning efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

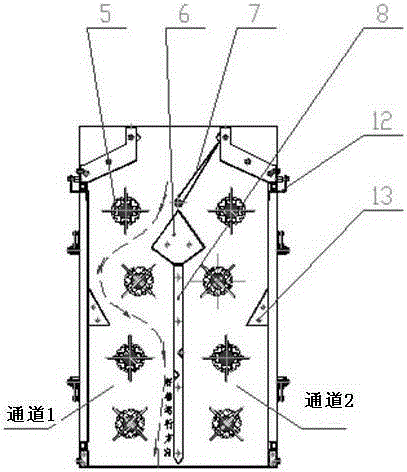

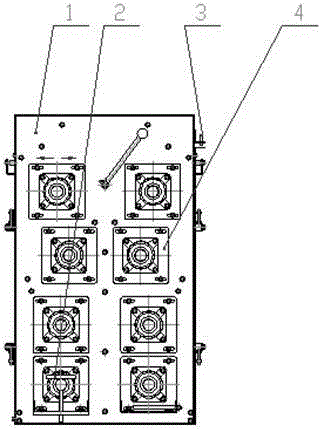

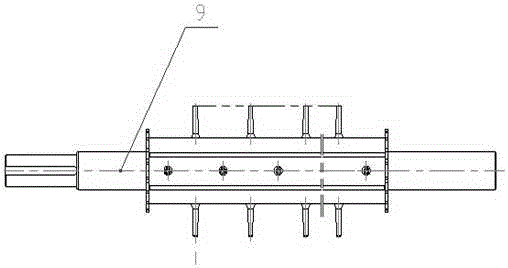

[0024] Referring to the accompanying drawings, it shows a seed cotton heterogeneous fiber processing system, including wallboard support 1, safety bolt 2, proximity switch 3, winding roller adjustment plate 4, winding roller 5, diverter plate 6, turning plate 7, and middle partition 8. The winding roller 4 includes a winding roller shaft 9, a thorn 11 riveted on the bent plate 10, and a toothed end plate welded on the bent plate 10 and the winding roller. The flap system includes a flap 7 and a wall support The handle on the outside, the middle partition 8 is an integral structure.

[0025] The safety pin 2 is set on the wallboard support (1) of the seed cotton foreign fiber processing system, and the proximity switch 3 is set above the door 12 of the seed cotton foreign fiber processing system. Prevent the rotation of the winding roller at the same time as the electrical appliance, to ensure the personal safety of workers.

[0026] The winding roller adjustment plate 4 is s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com