No-glue cotton feeder with cotton mixing device

A technology of cotton feeding machine and non-adhesive cotton, which is applied in the field of cotton feeding machine, can solve the problems of inaccurate ratio and uneven mixing of artificially applied cotton materials, and achieve the effect of accurate ratio, uniform mixing ratio and precise mixing ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

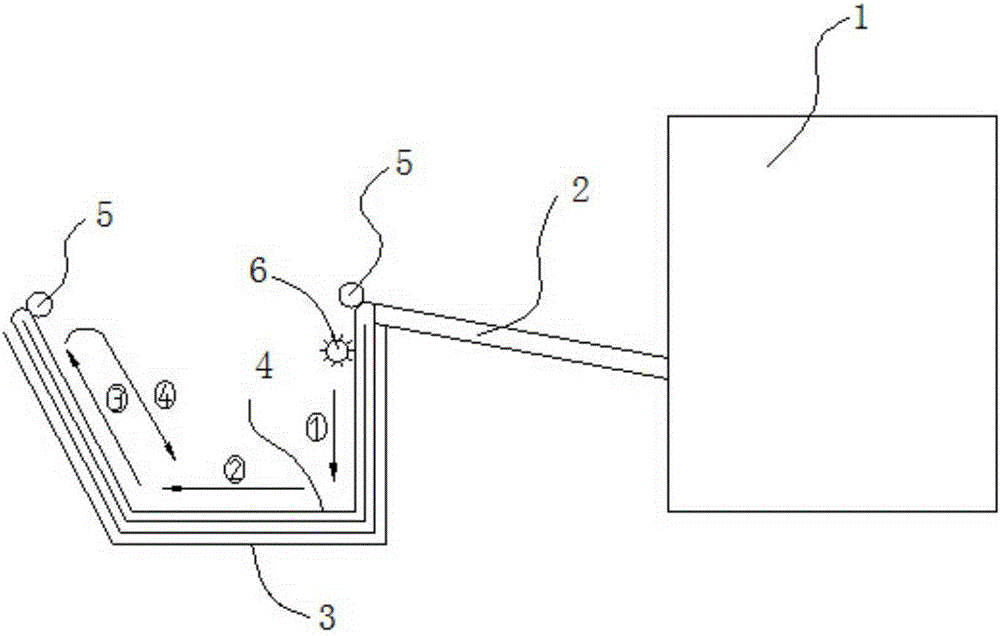

[0021] Such as figure 1 As shown, a cotton feeding machine for glue-free cotton with a cotton mixing device includes a cotton feeding machine body and a cotton depositing conveyor belt connected to the cotton feeding machine body, and also includes a cotton mixing device. The entrance of the cotton mixing device and the cotton depositing The ends of the conveyor belt are connected, and the outlet of the cotton mixing device is connected with the feed port of the opener; the cotton mixing device includes a cotton box, a feeding conveyor belt, two conveying rollers and a breaking roller, and the box wall of the cotton box is divided into two parts. It is the inner wall and the outer wall, and there is a hollow interlayer between the inner and outer walls. The feeding conveyor belt is fixed on the inner wall of the cotton box, and the hollow interlayer between the inner and outer walls can accommodate the feeding conveyor belt; A conveying roller is provided respectively, and a b...

Embodiment 2

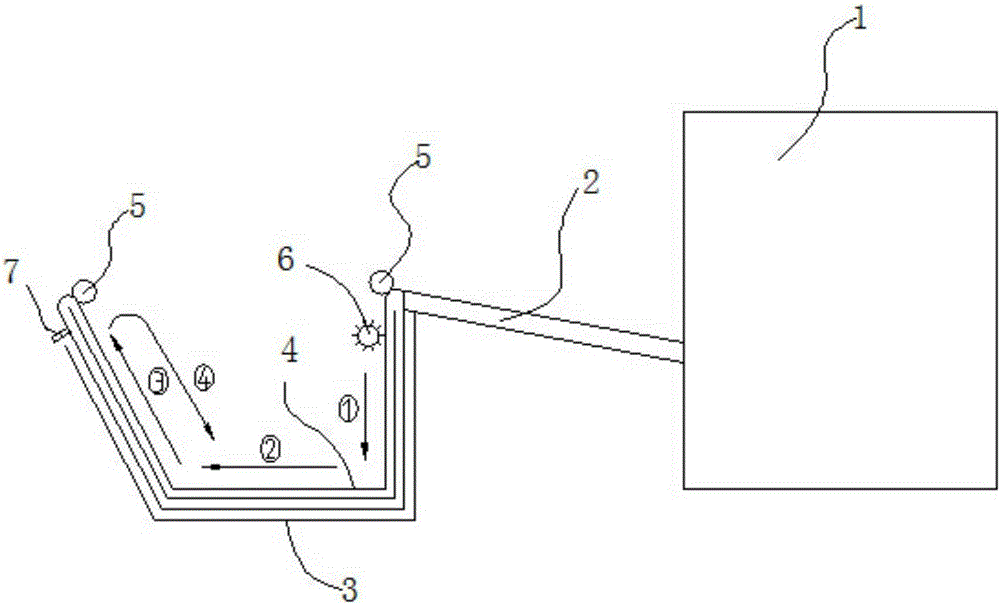

[0023] Such as figure 2 , image 3 As shown, a cotton feeding machine for glue-free cotton with a cotton mixing device includes a cotton feeding machine body and a cotton depositing conveyor belt connected to the cotton feeding machine body, and also includes a cotton mixing device. The entrance of the cotton mixing device and the cotton depositing The ends of the conveyor belt are connected, and the outlet of the cotton mixing device is connected with the feed port of the opener; the cotton mixing device includes a cotton box, a feeding conveyor belt, two conveying rollers and a breaking roller, and the box wall of the cotton box is divided into two parts. It is the inner wall and the outer wall, and there is a hollow interlayer between the inner and outer walls. The feeding conveyor belt is fixed on the inner wall of the cotton box, and the hollow interlayer between the inner and outer walls can accommodate the feeding conveyor belt; A conveying roller is provided respecti...

Embodiment 3

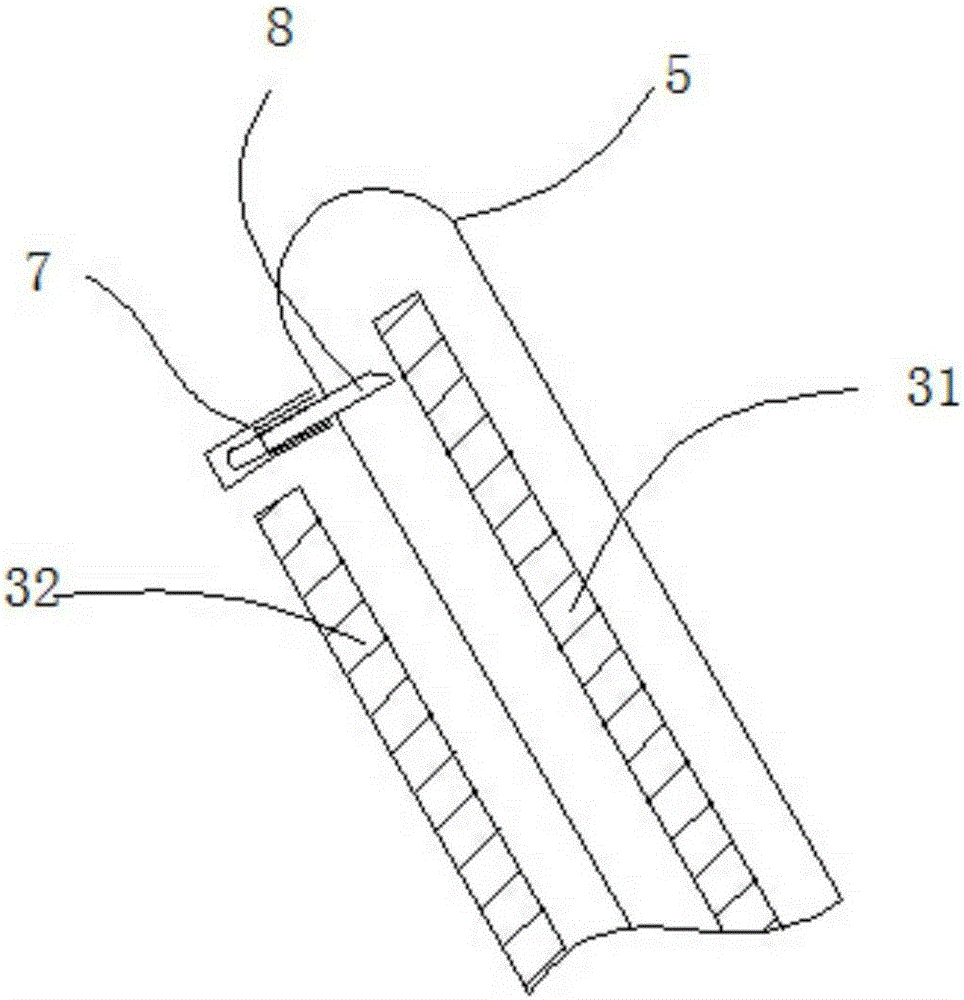

[0026] Such as Figure 4 , Figure 5 As shown, a cotton feeding machine for glue-free cotton with a cotton mixing device includes a cotton feeding machine body and a cotton depositing conveyor belt connected to the cotton feeding machine body, and also includes a cotton mixing device. The entrance of the cotton mixing device and the cotton depositing The ends of the conveyor belt are connected, and the outlet of the cotton mixing device is connected with the feed port of the opener; the cotton mixing device includes a cotton box, a feeding conveyor belt, two conveying rollers and a breaking roller, and the box wall of the cotton box is divided into two parts. It is the inner wall and the outer wall, and there is a hollow interlayer between the inner and outer walls. The feeding conveyor belt is fixed on the inner wall of the cotton box, and the hollow interlayer between the inner and outer walls can accommodate the feeding conveyor belt; A conveying roller is provided respect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com