Tailoring machine for clothing production

A cutting machine and clothing technology, applied in the field of clothing production, can solve problems such as affecting the safety of operators, wasting manpower, affecting processing work, etc., to avoid dust absorption, improve the quality of finished products, and reduce labor.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

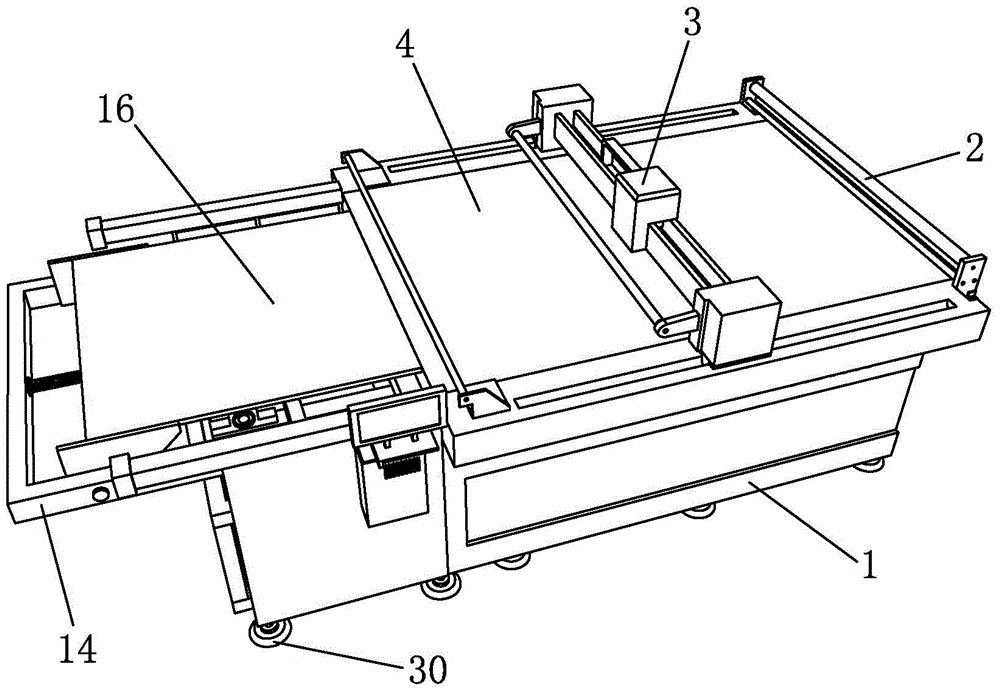

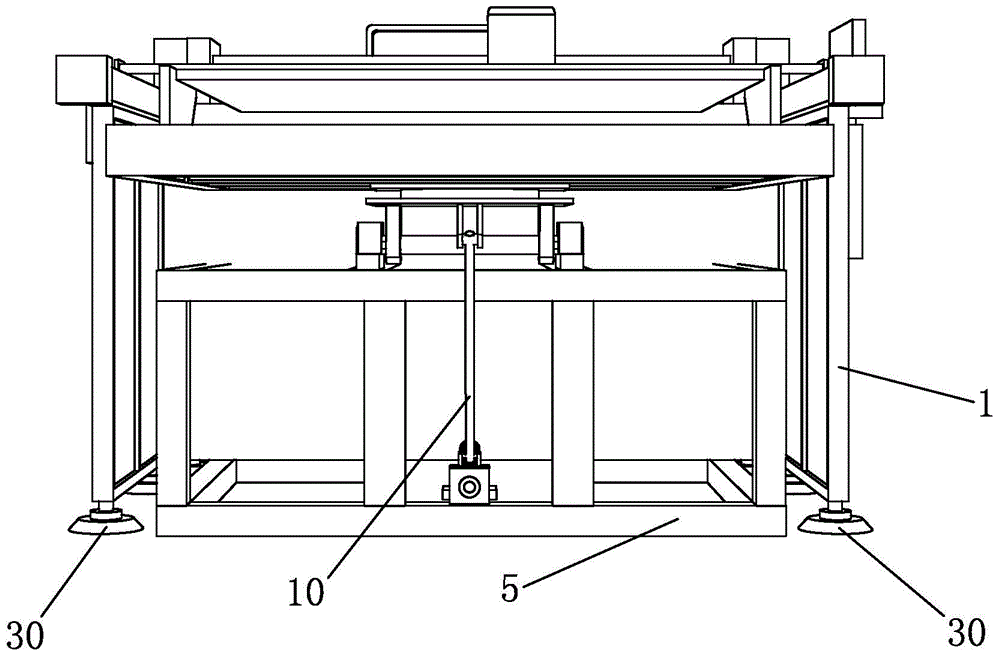

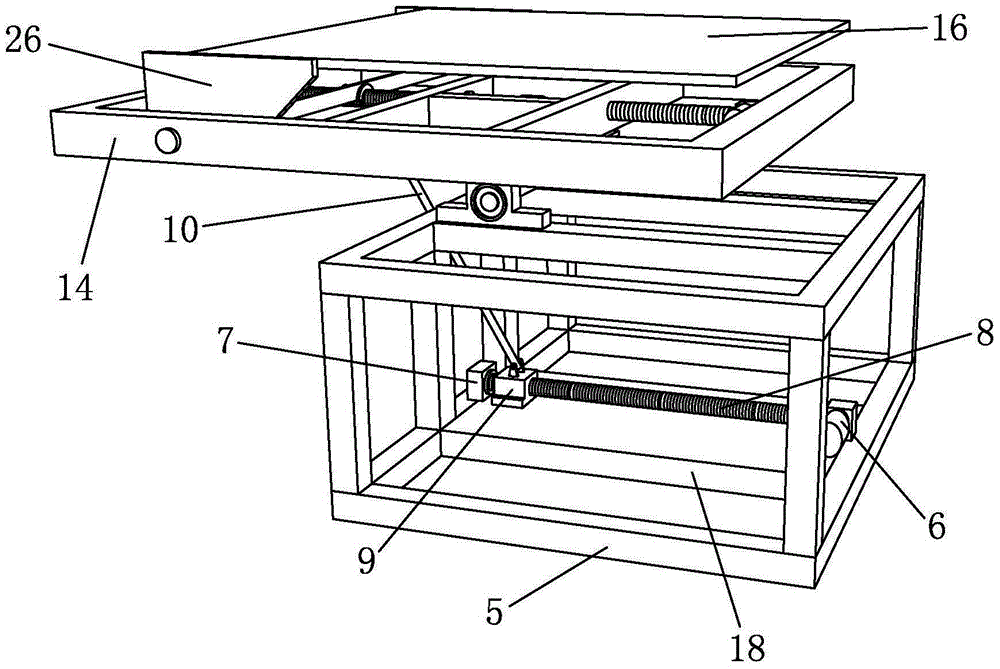

[0026] Such as Figure 1 to Figure 6 Shown is a cutting machine for garment production according to the present invention, which includes a frame 1 , an upper cloth frame 2 and a cutting mechanism 3 . The material of frame 1 should be made of light and high-strength materials as far as possible, generally made of aluminum alloy and ultra-thin steel plate. When frame 1 is in contact with the ground, the bottom of frame 1 will be slightly worn, and frame 1 is in contact with the ground. There will be a certain degree of slipping phenomenon on the ground, in order to prevent the occurrence of this type of phenomenon, to prolong the service life of the frame 1, the present invention is provided with a leg 30 at the bottom of the frame 1, the leg 30 supports the frame 1, and the frame 1 Raise a certain height, the support foot 30 is provided with anti-slip structure, the anti-slip structure adopts the aluminum core copper to wrap the hard rubber material outside, the hard rubber ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com