Construction Method for Removing Anchor Bar Obstacles During Grooving Process of Underground Diaphragm Wall

A technology of underground diaphragm wall and construction method, which is applied in the direction of excavation, sheet pile wall, foundation structure engineering, etc. It can solve the problems affecting the safety of surrounding buildings and structures, the collapse of groove walls, etc., and achieve the purpose of preventing hole collapse and requiring small site space , to ensure the effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

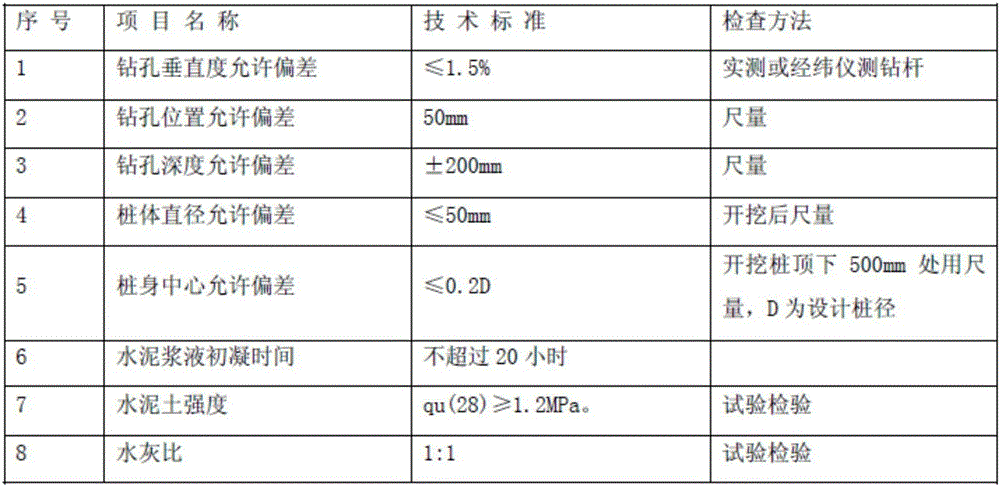

[0049] Embodiment: The construction method of removing the anchor bar obstacle in the process of forming the underground diaphragm wall in this example, the steps are:

[0050] A. Construction preparation:

[0051] a. Level the site, reasonably arrange the material shed and the installation location of machinery and equipment, the location of water and electricity connectors and drainage ditch, and shorten the distance of high-pressure hoses as compactly as possible;

[0052] b. Calibrate the hole position according to the design;

[0053]c. Set up temporary sheds to store a certain amount of materials;

[0054] d. Mechanical maintenance, dry running, load running, test spraying;

[0055] B. Rig in place:

[0056] The frame of the drilling rig is made of welded section steel. The lower part is made of two thicker steel pipes as a platform and a moving roller. The steel pipes are underlaid with square wood. The frame is placed stably on the platform, the drill pipe is verti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com