Self-reset viscous-elastic damping wall

A viscoelastic, self-resetting technology, applied in the direction of walls, building components, earthquake resistance, etc., can solve problems such as limited energy consumption capacity, and achieve the effect of improving energy consumption capacity, reducing maintenance probability or reconstruction probability, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

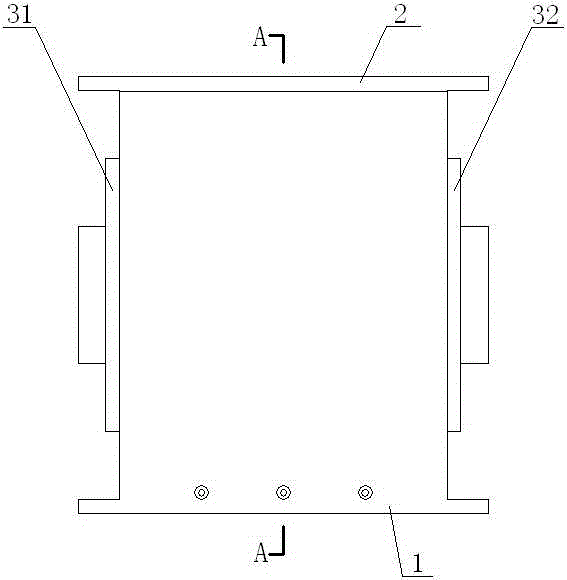

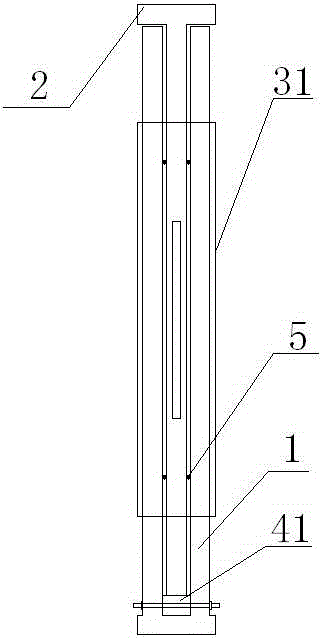

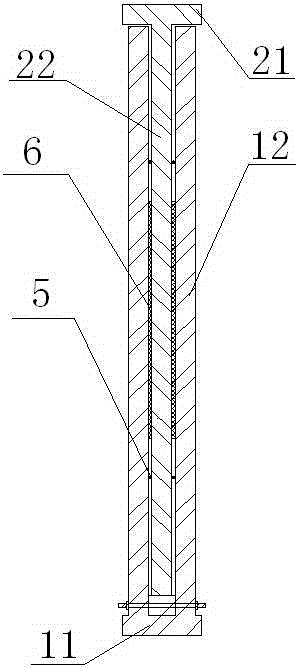

[0029] Combine below Figure 1 to Figure 9 The structure and working process of the present invention are further described.

[0030] The self-resetting viscoelastic damping wall of the present invention includes a double T-shaped steel box body 1, a T-shaped steel plate 2, a left cover plate 31 and a right cover plate 32, and both the left cover plate 31 and the right cover plate 32 are rectangular steel cover plates The double T-shaped steel box 1 includes a lower flange plate 11 and two box body webs 12, the two box body webs 12 are arranged in parallel and fixedly arranged on the lower flange plate 11, the lower flange plate 11 and the two Two box webs 12 form an inverted double T-shaped structure, and a steel roller 41 is arranged between the two box webs 12 near the lower flange plate 11, and the axial direction of the steel roller 41 is in line with the box body. The web 12 is vertical, and the lower edge of the steel roller 41 is close to the lower flange plate 11 of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com