A crawler walking self-rotating two-way drilling coal mining machine and its use method

A shearer, self-rotating technology, applied in drilling equipment and methods, earthwork drilling, drilling equipment, etc., can solve the problems of increased movement time of equipment during coal mining, inability to achieve simultaneous mining, and high labor intensity of workers, and achieve Wide practicality, saving moving time, improving coal mining efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] An embodiment of the present invention will be further described below in conjunction with accompanying drawing:

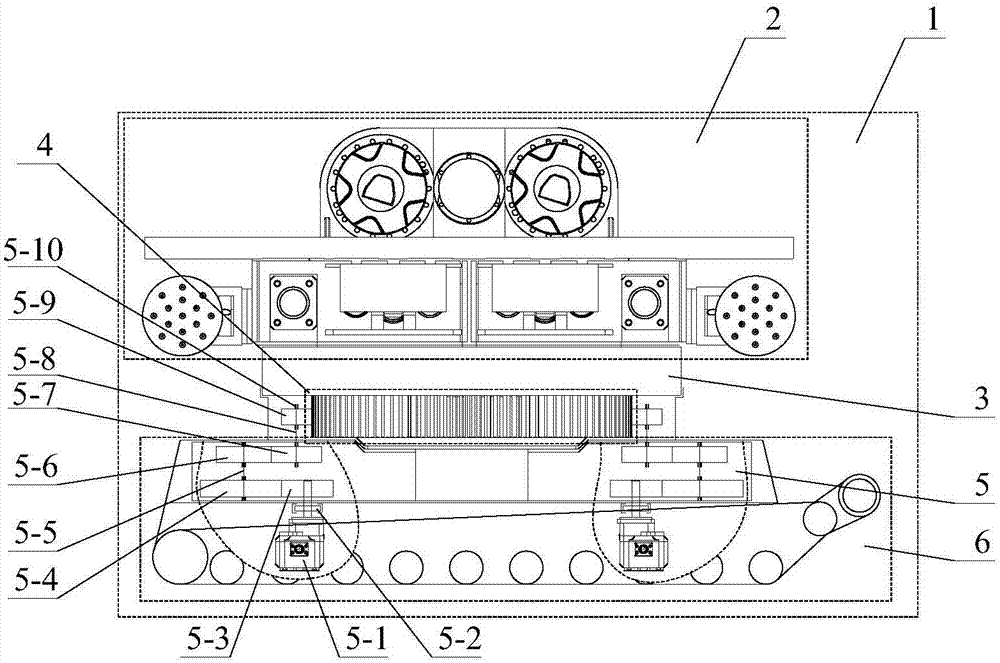

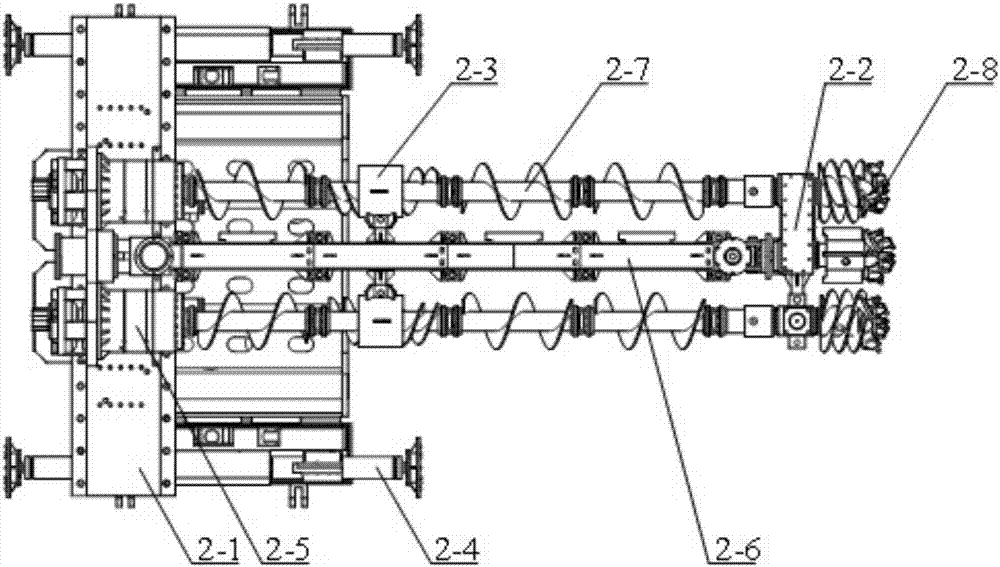

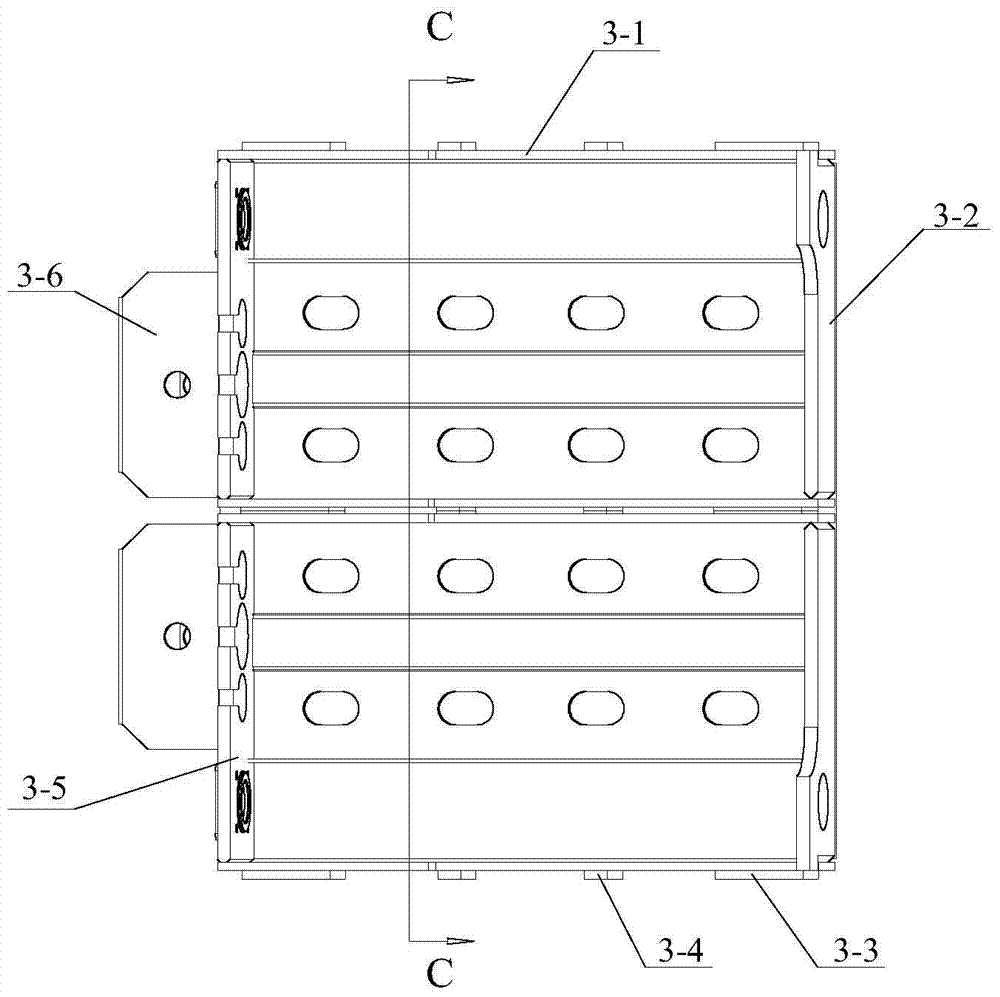

[0025] The crawler walking self-rotating two-way drilling shearer of the present invention comprises a shearer upper frame assembly 2, a shearer base 3 arranged under the shearer upper frame assembly 2, and a slewing support is provided under the shearer base 3 Device 4, a crawler running mechanism 6 is provided under the slewing support device 4, and a transmission device 5 connected with the slewing support device 4 is arranged on the crawler running mechanism 6;

[0026] The slewing support device 4 includes an inner ring 4-1, an outer ring 4-3 sleeved on the inner ring 4-1, a rolling ball 4-2 is arranged between the inner ring 4-1 and the outer ring 4-3, The outer ring 4-3 is fixed together with the shearer base 3 via bolts, and the inner ring 4-1 is fixed together with the crawler belt traveling mechanism 6 via bolts;

[0027] The crawler belt running...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com