Burner

A burner, spiral channel technology, applied in the burner, combustion method, combustion type and other directions, can solve the problems of insufficient combustion of pulverized coal, unsatisfactory degree of change, etc., so that the shape and size of the flame are more easily adjustable, easy to change, well-mixed effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

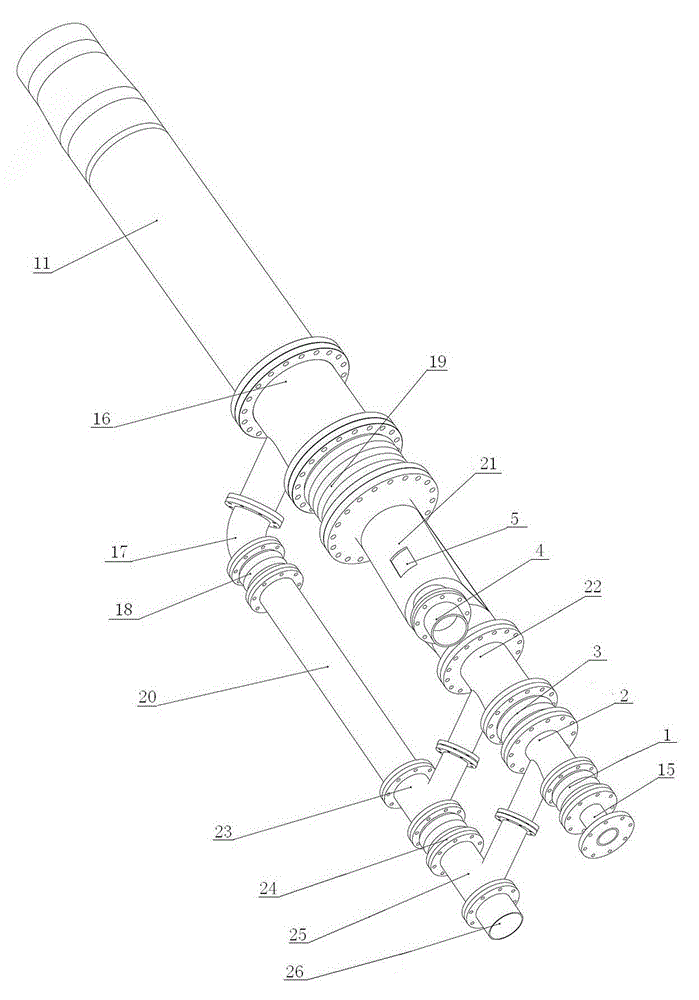

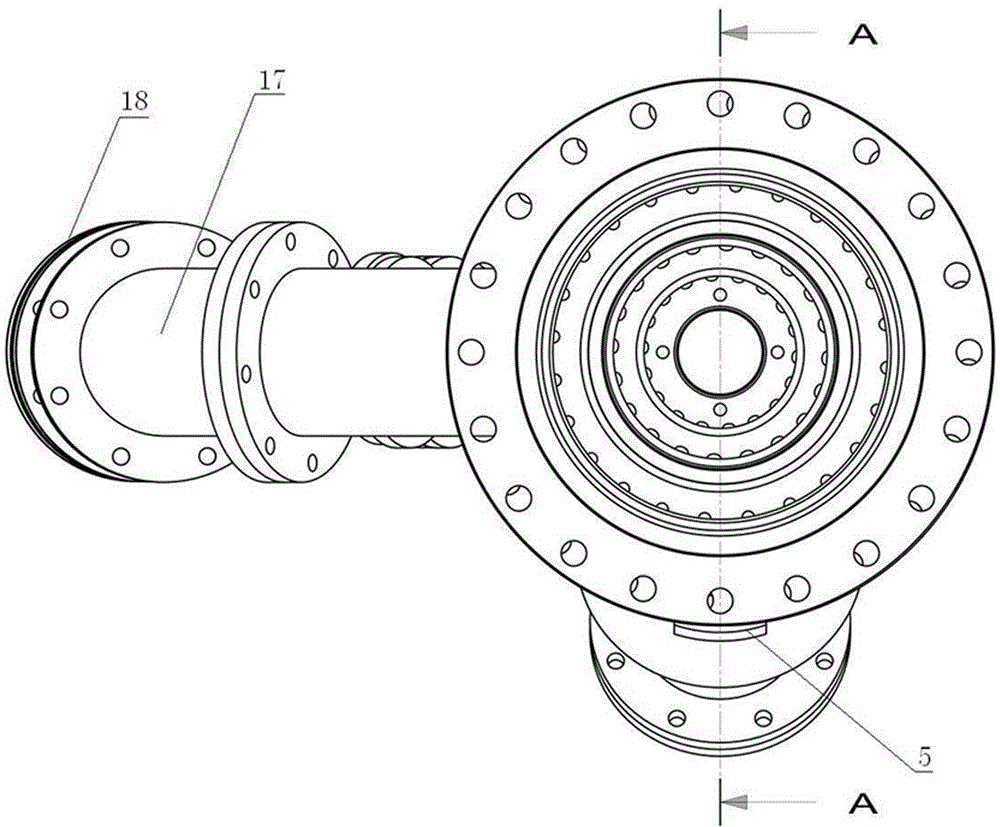

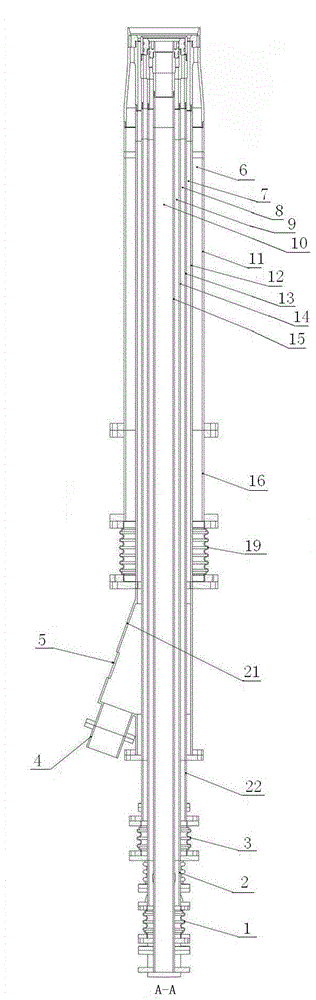

[0021] Such as Figure 1-5 As shown, a burner includes a central oil injection channel 10, and the oil injection channel 10 is outwardly followed by a vortex air duct 9, a swirl air duct 8, a pulverized coal air duct 7, and an outer axial flow air duct 6, wherein the vortex air duct Road 9 is composed of vortex cone-shaped spiral passages with the same rotation direction, swirl air passage 8 is composed of swirl cone-shaped spiral passages with the same rotation direction, and outer axial flow air passage 6 is composed of outer axial wind cones with the same rotation direction. form a spiral channel. The central axis of the conical spiral channel of the vortex channel 9, the swirl channel 8, and the outer axial flow air channel 6 is a cylindrical helix, and its rise angle is 15°-25°, and the taper of the conical spiral channel is 8°-15° change between.

[0022] The rotation direction of the vortex conical helical channel and the rotational direction of the swirl conical heli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com