A multi-probe friction and wear test and in-situ shape detection system under vacuum

A friction and wear, detection system technology, applied in the direction of testing wear resistance, etc., can solve the problems of sample leakage, deviation of test results, unfavorable scientific analysis of experimental results, etc., to increase internal space, save adjustment and calibration time, The effect of convenient optical path adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

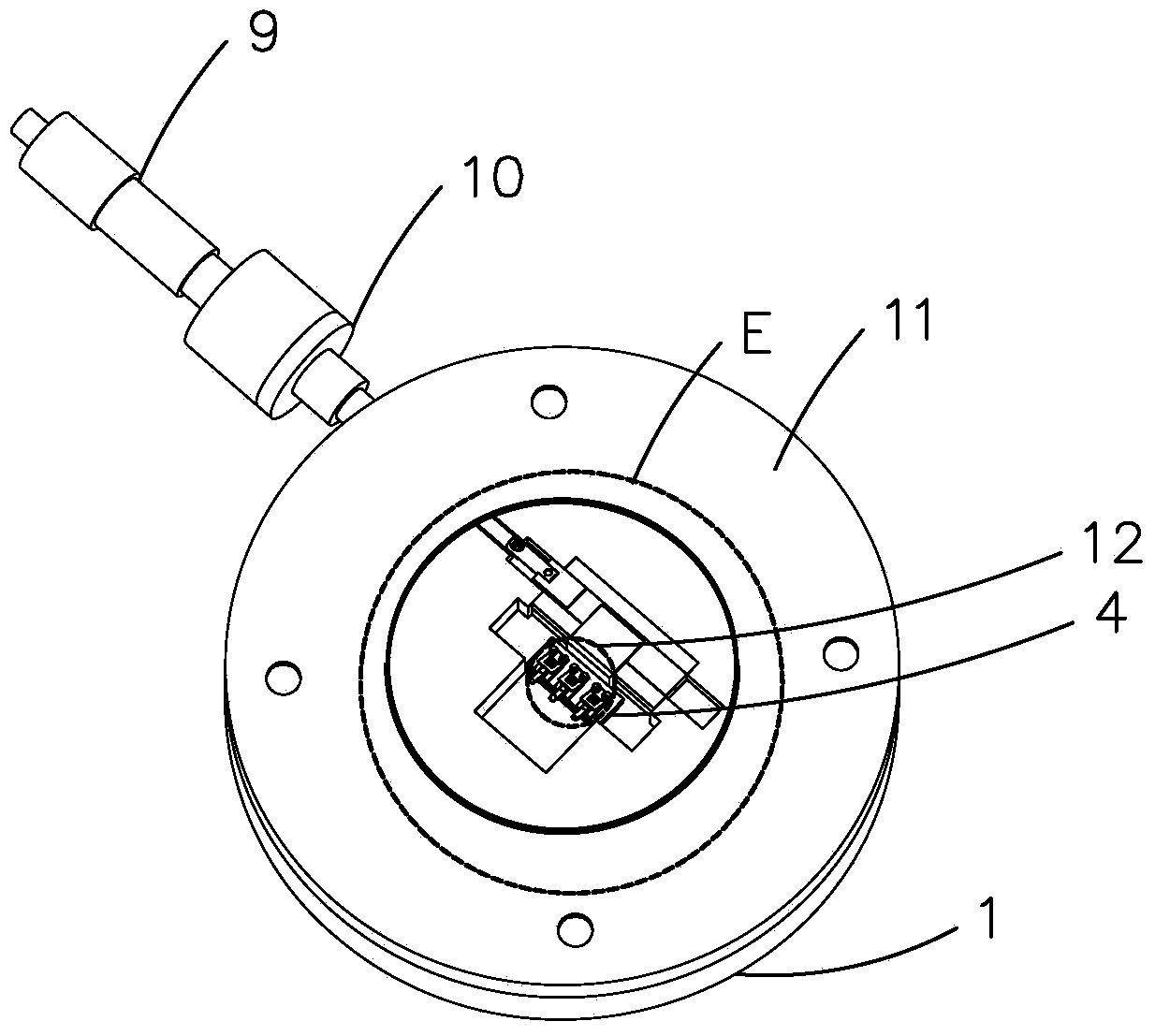

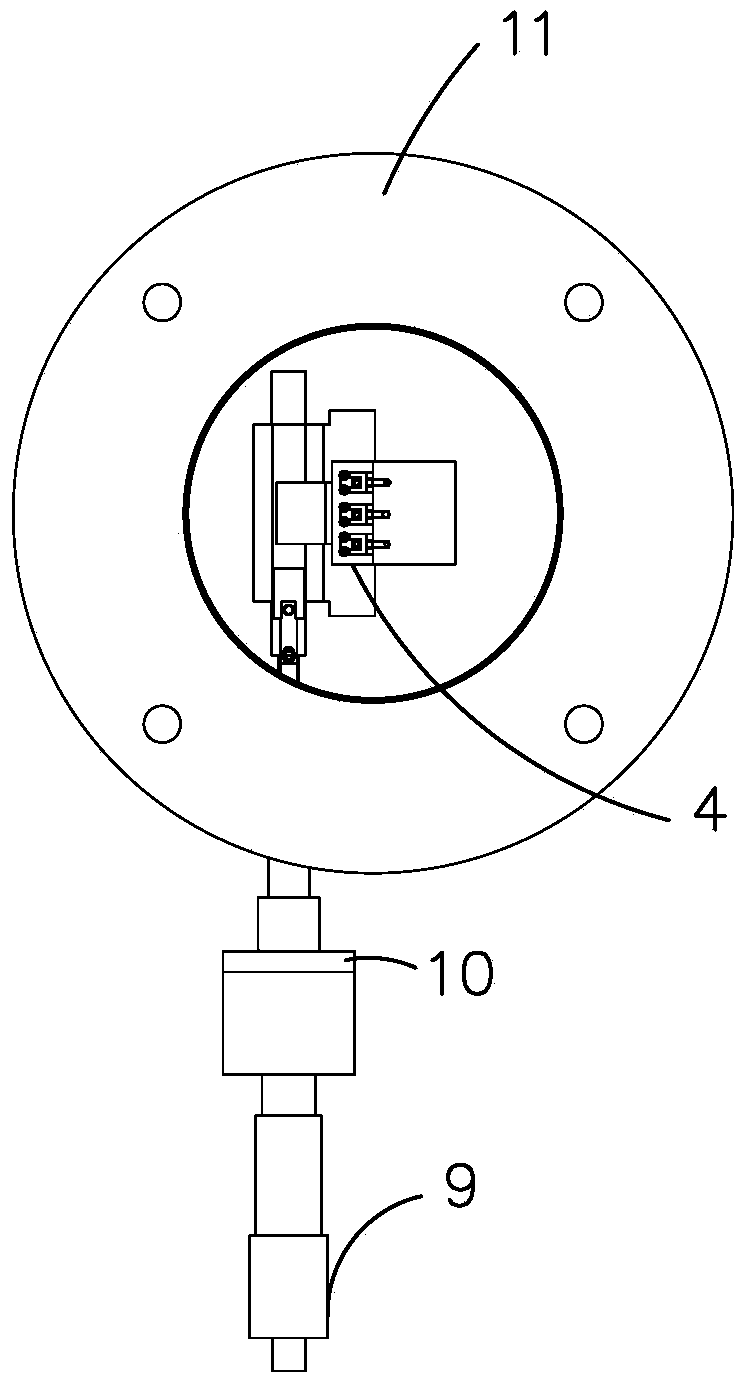

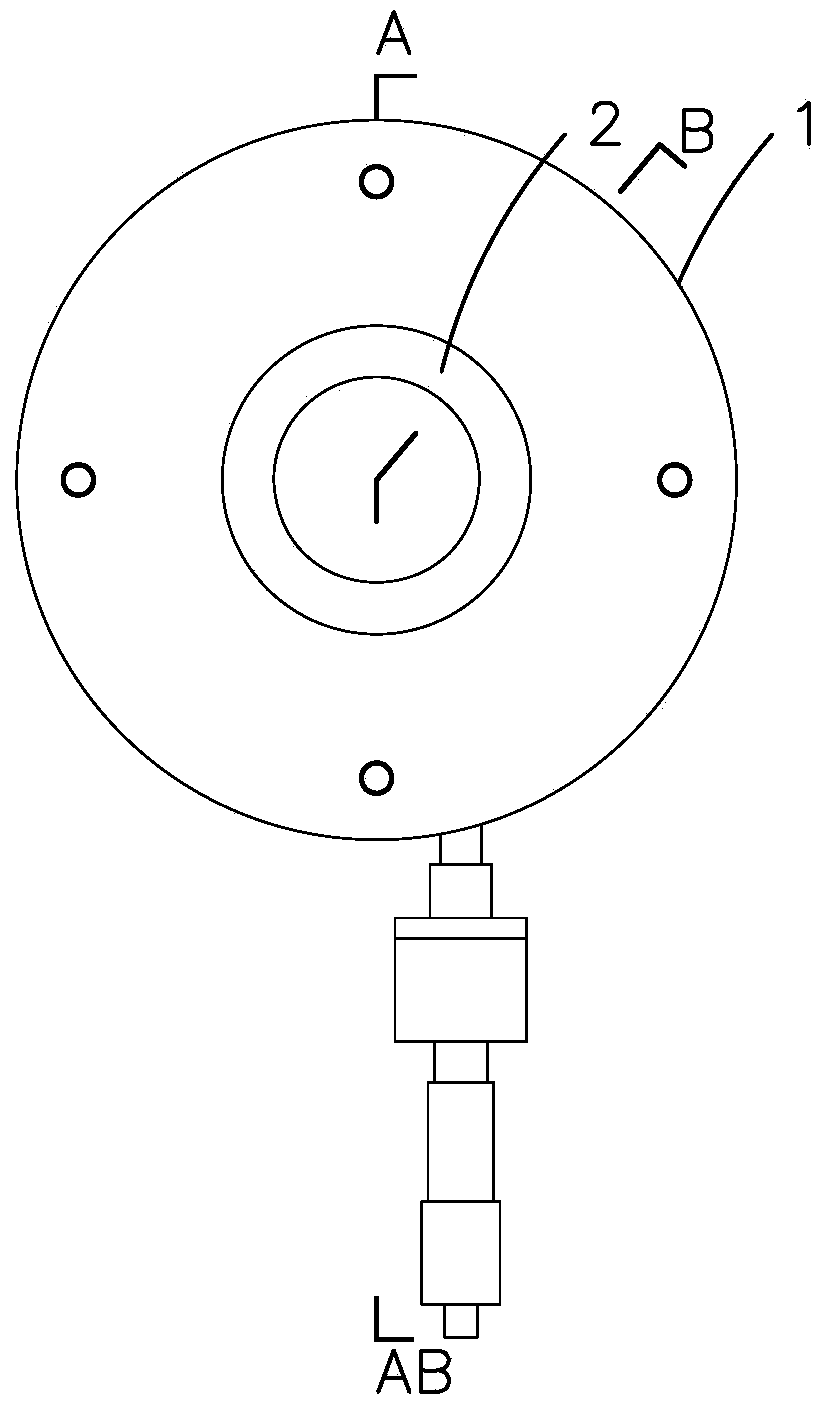

[0030] Such as Figure 1-8 Shown, a kind of specific embodiment of the present invention is:

[0031] A multi-probe in-situ friction and wear test and in-situ shape detection system under vacuum, including a main body and an external manual drive device 9; the main body includes a cavity upper cover 1, and a light window top cover installed on the cavity upper cover 1 2 and the multi-probe assembly inside the upper cover 1 of the installation cavity; a vacuum flange 10 for ensuring dynamic connection sealing is provided between the main body and the external manual drive device 9 .

[0032] The multi-probe assembly includes a plurality of probes 12, preferably the number of probes 12 is 2-3, a moving plate 4 for carrying the probes 12 and carrying them to switch positions in situ, and a transition point connected to one side of the moving plate 4. Plate 5, a guide rail 6 used to ensure the stability of the in-situ switching positioning movement of the needle point, and a conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com