Energy-saving coordination control method for coal-fired power units

A thermal power generation unit, coordinated control technology, applied in the direction of electrical program control, program control, comprehensive factory control, etc., can solve the problem of large throttling loss of capacity air regulating valve, achieve the effect of convenient configuration and improved economy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0031] The invention provides an energy-saving coordinated control method for a thermal power generating set, comprising the following steps:

[0032] (1) Fully open the capacity air regulating door of the coal mill;

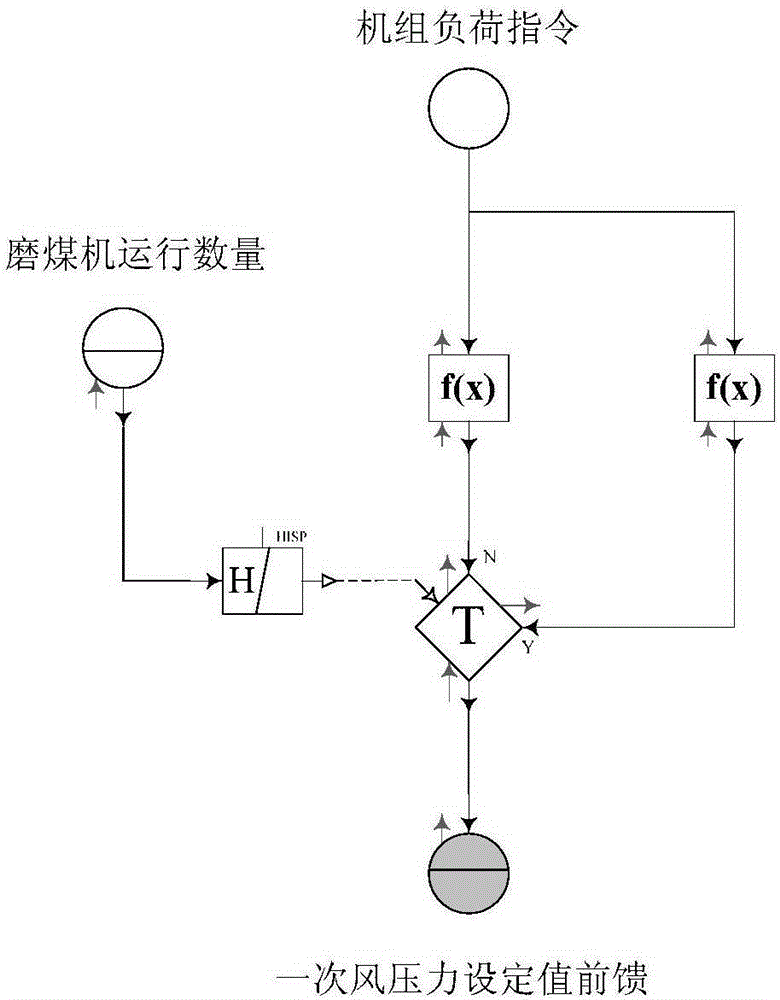

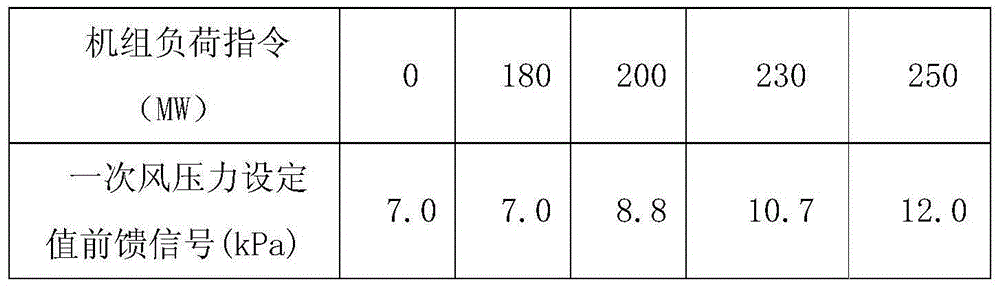

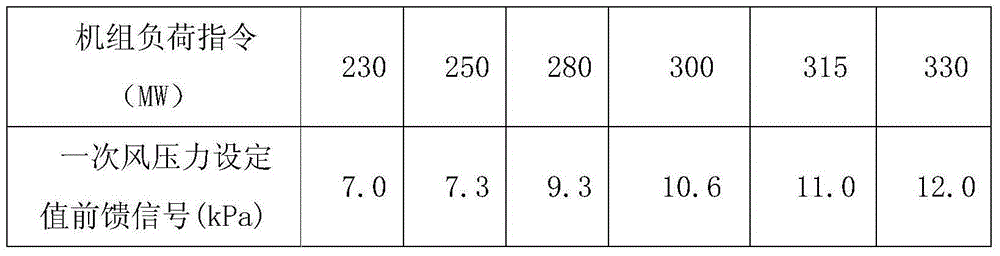

[0033] (2) Feedforward signal calculation of primary air pressure setting value. Such as figure 1 As shown, through the DCS analog input channel, the unit load command signal is taken, and the primary air pressure set value feedforward function is calculated to form the primary air pressure set value feedforward signal. The primary air pressure set value feedforward function corresponds to The relationship is shown in Table 1 and Table 2, and the specific function form is determined according to the operating data of the unit. The feed-forward function of the primary air pressure setting value in Table 1 and Table 2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com