Laser direct-write lithography machine precise temperature control method

A temperature control method, laser direct writing technology, applied in temperature control, non-electric variable control, control/regulation system, etc., can solve problems such as error, unstable temperature of laser direct writing lithography machine, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

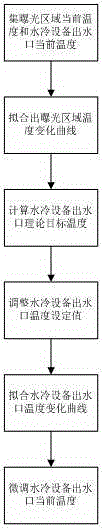

[0032] A preferred embodiment of the present invention will be described in detail below with reference to the accompanying drawings.

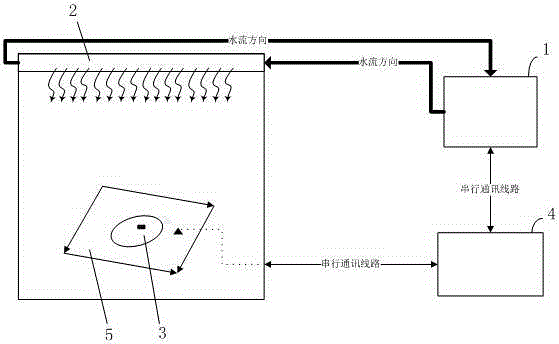

[0033] figure 1 It shows a schematic structural view of the temperature control system of the laser direct-writing lithography machine of the present invention, and the temperature control system of the laser direct-writing lithography machine includes a water-cooling device 1 with a communication port, and a condenser for heat exchange A fan filter unit 2, a high-precision temperature sensor 3 with a communication port, and an industrial computer 4 with a certain real-time response to commands.

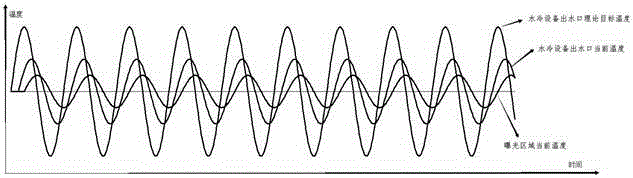

[0034] The temperature sensor 3 is installed on the exposure area 5 of the laser direct writing lithography machine, and the fan filter unit 2 is installed on the top of the machine for air circulation. The temperature of the exposure area in the machine is controlled at the target temperature. The temperature sensor 3 and the water cooling device...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com