Inclined gap type reactor iron core structure and production process thereof

A technology of iron core structure and reactor, which is applied in the direction of transformer/inductor magnetic core, circuit, electrical components, etc., can solve the problems of easy displacement and vibration, increased loss of accessories, etc., and achieve the reduction of magnetic voltage drop, noise and The effect of reduced loss and ingenious and practical structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

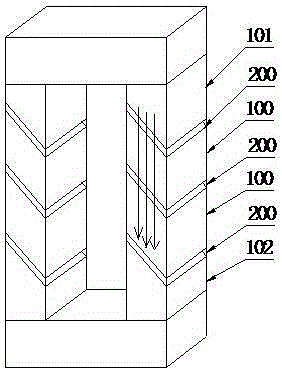

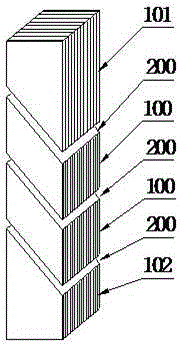

[0021] This embodiment discloses an inclined-plane air-gap reactor core structure, such as figure 1 As shown, it includes at least a plurality of silicon steel pieces 100 arranged in a row. The silicon steel piece 100 is composed of a plurality of stacked silicon steel sheets. An air gap is formed between two adjacent silicon steel pieces 100, and an air gap plate 200 is arranged in the air gap. , the air-gap plate 200 is bonded and fixed to the silicon steel piece by an adhesive. In this embodiment, the air gap is set obliquely, the angle between the air gap and the magnetic circuit is less than 180° and not equal to 90° (the arrow in the figure indicates the direction of the magnetic circuit), the air gap plate 200 is placed in the air gap, and the air gap plate 200 Tilt setting.

[0022] The silicon steel piece in this embodiment is provided with two kinds of shapes, see figure 1 and 2 , the silicon steel pieces on the upper and lower sides (namely 101 and 102) are arran...

Embodiment 2

[0030] This embodiment is basically the same as Embodiment 1, except that the air-gap plate of this embodiment uses a fiber insulation board with a rough surface, and the surface of the fiber insulation board has numerous fine burrs.

Embodiment 3

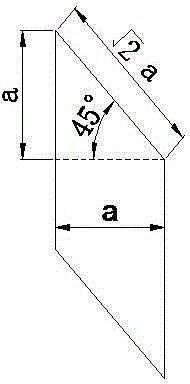

[0032] This embodiment is basically the same as Embodiment 2, the difference is that the angle between the air gap and the magnetic circuit in this embodiment is 45°, see image 3 , the area of the air gap is 1.414 times larger than the traditional one.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com