Sensorless tension identification method for two-motor speed regulating system

A technology of motor speed regulation and identification method, which is applied in multiple motor speed/torque control, electronic commutator and other directions, can solve the problems of difficult installation, many material and environmental constraints, and high-precision tension sensors are expensive. Achieve the effect of wide application range, high application value, enhanced approximation and anti-interference ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

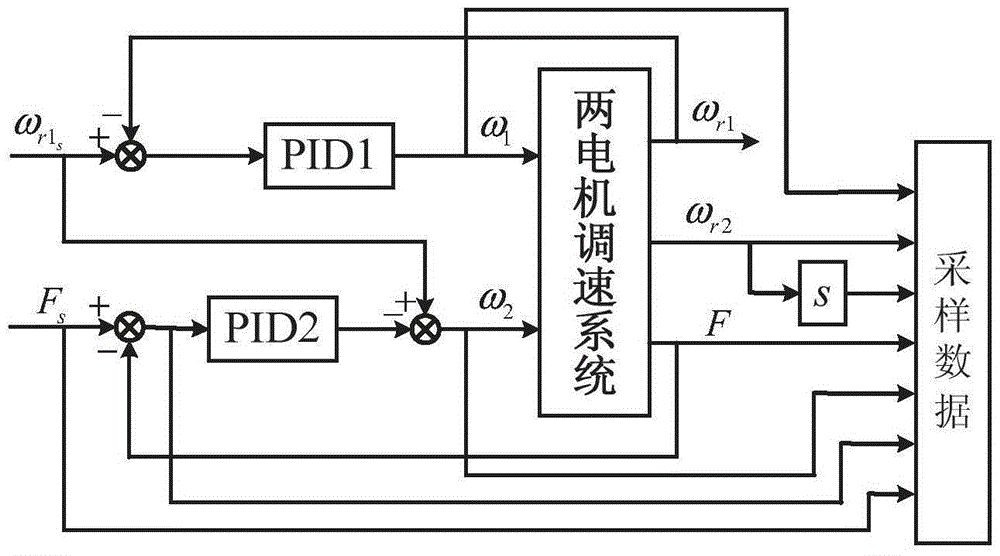

[0040] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

[0041] Embodiments of the present invention are described in detail below, examples of which are shown in the drawings, wherein the same or similar reference numerals designate the same or similar elements or elements having the same or similar functions throughout. The embodiments described below by referring to the figures are exemplary only for explaining the present invention and should not be construed as limiting the present invention.

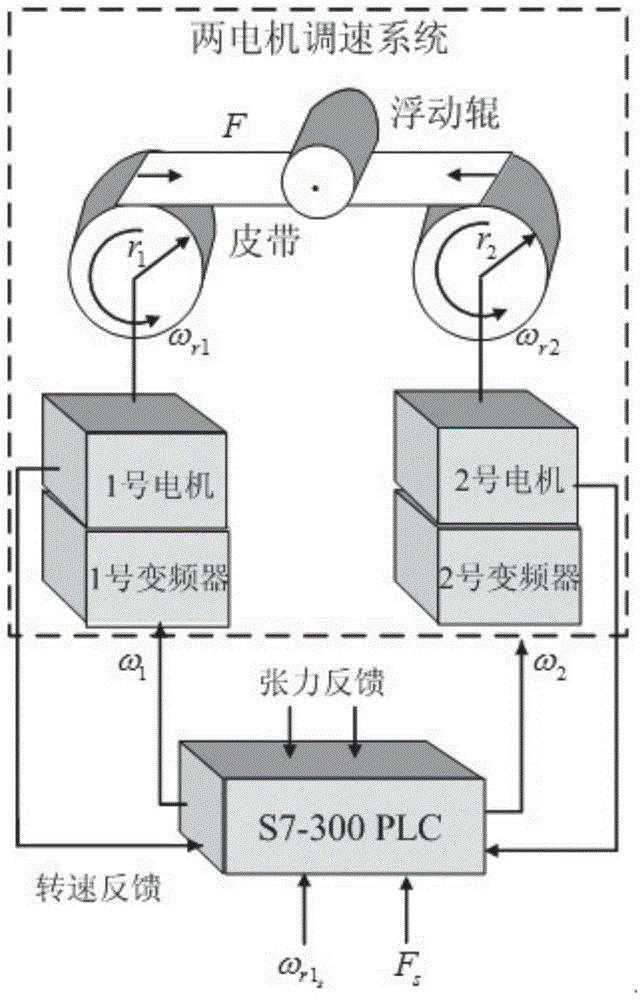

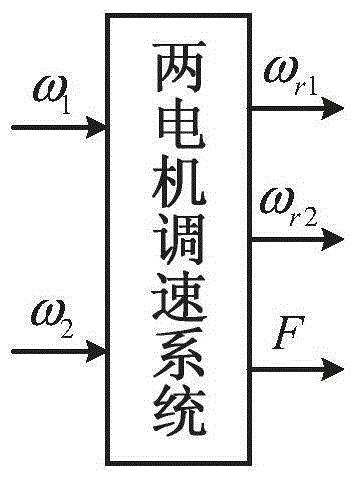

[0042] The present invention is as figure 1 The two-motor speed control system platform shown is implemented on the basis. The system includes two frequency converters and two induction motors. The induction motor is connected to the driving roller through a reducer. The two driving rollers are connected by a belt. The belt is equipped ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com