Grain noise detection fixture, device and method

A particle noise and detection fixture technology, applied in the direction of electrical components, electrical components, etc., can solve the problems of inability to realize particle noise detection and lower product qualification rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] Below in conjunction with accompanying drawing, invention is described in further detail.

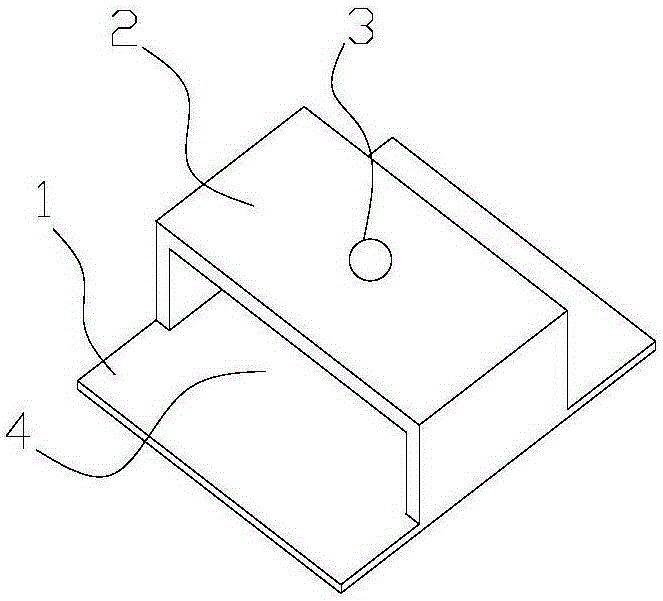

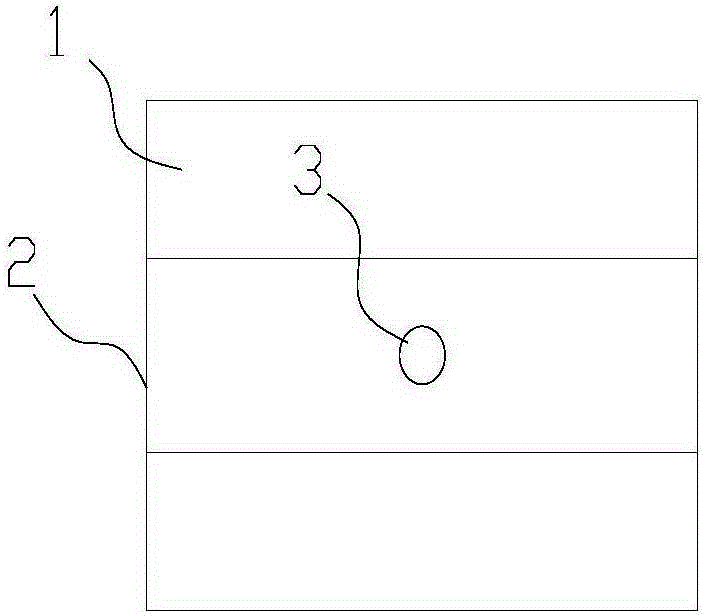

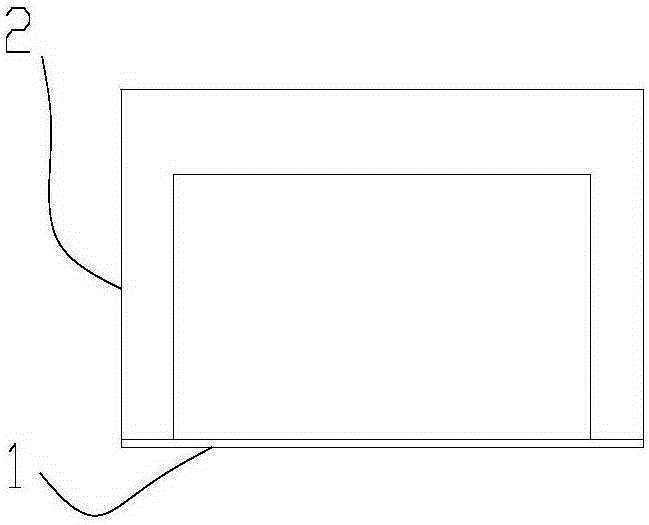

[0034] Figure 1~4 A particle noise detection jig according to an embodiment of the present invention is schematically shown. The fixture includes a base 1, a clamping frame 2 integrally formed with the base located on one side of the base 1, and the clamping frame 2 and the base 1 are enclosed to form a space for accommodating the component to be detected (for example, a circuit to be detected) The cavity 4 and the clamping frame 2 are provided with one or more fastener mounting holes 3 communicating with the cavity 4, and the fastener mounting holes 3 are bolt holes.

[0035] In practical application, place the component to be tested in the cavity 4, screw the bolts into the cavity 4 through the bolt holes until the bolts withstand the component to be tested, and then properly tighten the bolts to fasten the component to be tested. The operation is simple and convenient, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com