Sediment collecting device for organisms

A collection device and biological technology, applied in the direction of cleaning hollow objects, cleaning methods and utensils, chemical instruments and methods, etc., can solve problems such as low work efficiency, poor cleaning effect, and difficult fixing of petri dishes, so as to improve work efficiency and prevent drop effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

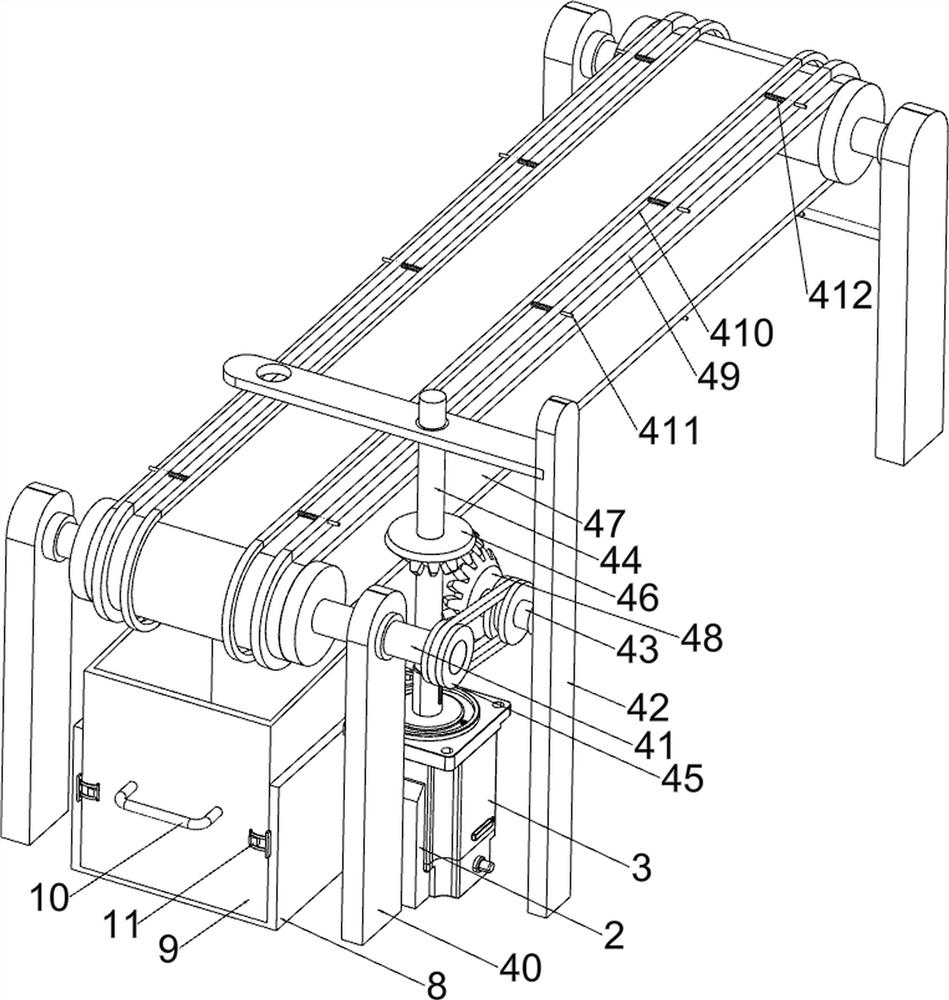

[0023] A sediment collection device for biological, such as figure 1 As shown, it includes a bottom plate 1, a fixed seat 2, a servo motor 3, a feeding mechanism 4, a rotating mechanism 5, a cleaning mechanism 6 and a material receiving mechanism 7. Servo motor 3, base plate 1 top is provided with feeding mechanism 4, base plate 1 top rear side is provided with rotating mechanism 5, base plate 1 top middle part is provided with cleaning mechanism 6, base plate 1 top front side is provided with material receiving mechanism 7.

[0024] The staff fixes the culture dish on the feeding mechanism 4, then starts the servo motor 3 to work, the servo motor 3 drives the feeding mechanism 4 to work, the feeding mechanism 4 moves the culture dish to the bottom of the rotating mechanism 5, and the feeding mechanism 4 drives the rotating mechanism 5 to work, The rotating mechanism 5 removes the sediment in the petri dish, and then the petri dish moves below the feeding mechanism 4 to make t...

Embodiment 2

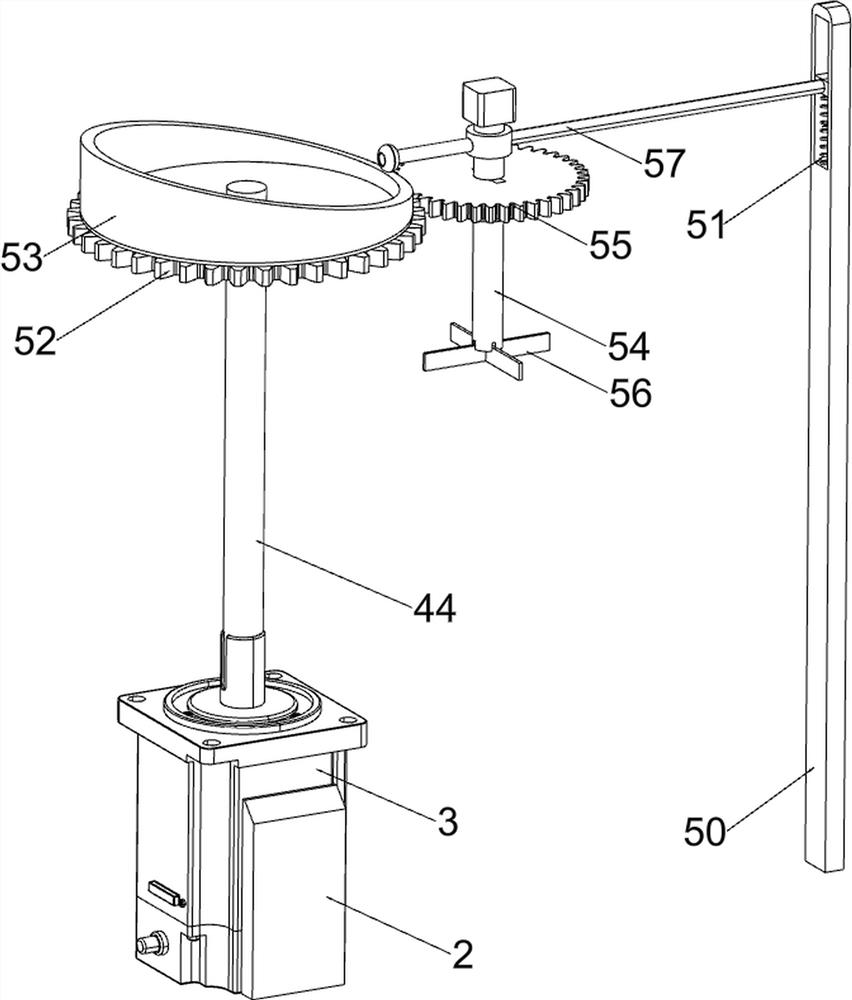

[0026] On the basis of Example 1, such as Figure 2-5 As shown, the feeding mechanism 4 includes a first support plate 40, a first rotating shaft 41, a support frame 42, a second rotating shaft 43, a third rotating shaft 44, a first pulley assembly 45, a half gear 46, a first conveyor belt 47, a first Bevel gear 48, limit ring 49, rubber ring 410, first connecting rod 411 and first spring 412, four first support plates 40 are evenly arranged on the top of bottom plate 1, and the first support plates 40 on the same side are all rotated The first rotating shaft 41 is connected in a formula, the left side of the top of the bottom plate 1 is provided with a support frame 42, and the middle part of the support frame 42 is rotatably provided with a second rotating shaft 43, and the second rotating shaft 43 is connected with a first bevel gear 48. A first pulley assembly 45 is connected between the rotating shaft 41 and the second rotating shaft 43, a third rotating shaft 44 is conne...

Embodiment 3

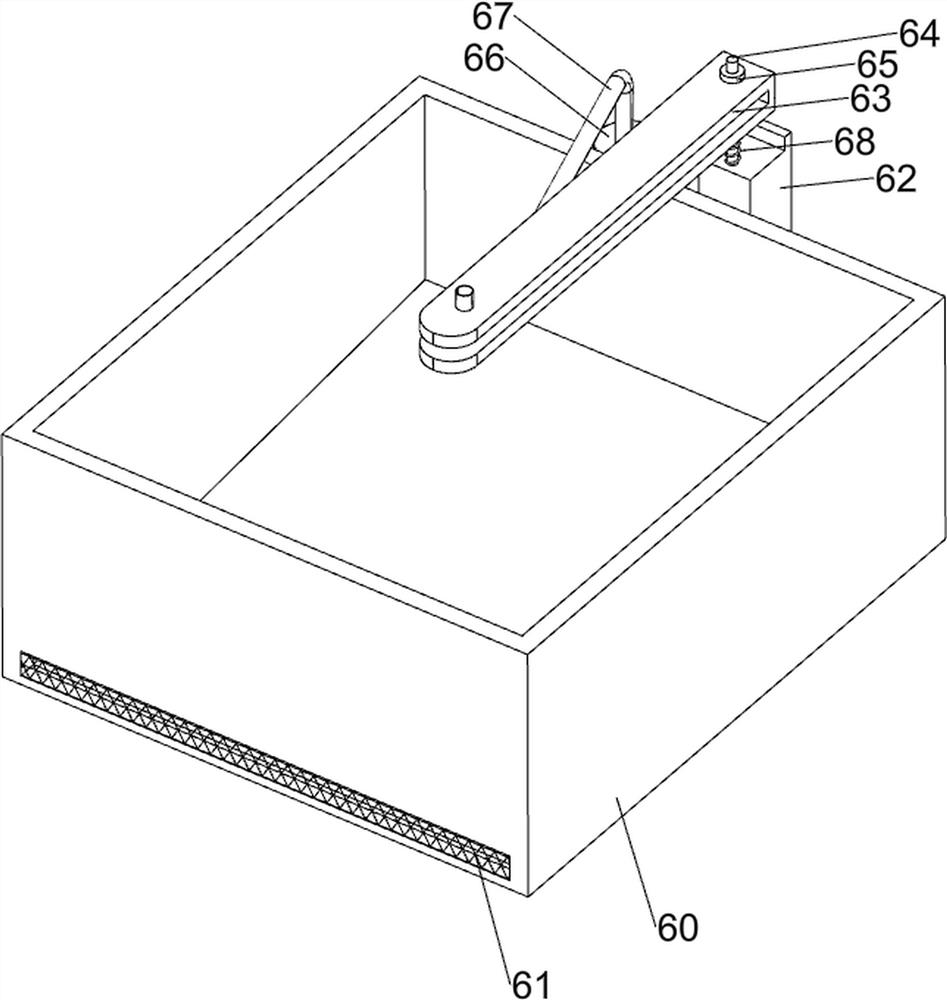

[0035] On the basis of Example 2, such as figure 2 and Figure 5 As shown, it also includes a placement basket 8, a storage basket 9, a handle 10 and a clamping switch 11. The rear side of the top of the bottom plate 1 is provided with a placement basket 8, and the placement basket 8 is slidingly connected with a storage basket 9, and the rear side of the storage basket 9 A handle 10 is provided, and a locking switch 11 is installed between the placement basket 8 and the storage basket 9 .

[0036] The staff can place the storage basket 9 in the placement basket 8, and buckle the clamping switch 11 to fix the storage basket 9. When the culture dish moves to the bottom surface of the first conveyor belt 47, the sediment in the culture dish will drop to In the storage basket 9, when the storage basket 9 needs to be taken out after all the sediments have been collected, the locking switch 11 is turned on, and the handle 10 is pulled to pull the storage basket 9 out, thereby col...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com