System and method for controlling pump performance in a transmission

A technology of controller and hydraulic system, which is applied in the direction of transmission, transmission control, fluid transmission, etc., which can solve the problems of filling clutch unnecessary time delay, affecting fuel economy and shifting quality, and increasing hydraulic demand, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The embodiments of the invention described below are not intended to be exhaustive or to limit the invention to the precise forms disclosed in the following detailed description. Rather, the embodiments were chosen and described so that others skilled in the art can understand and understand the principles and practice of the invention.

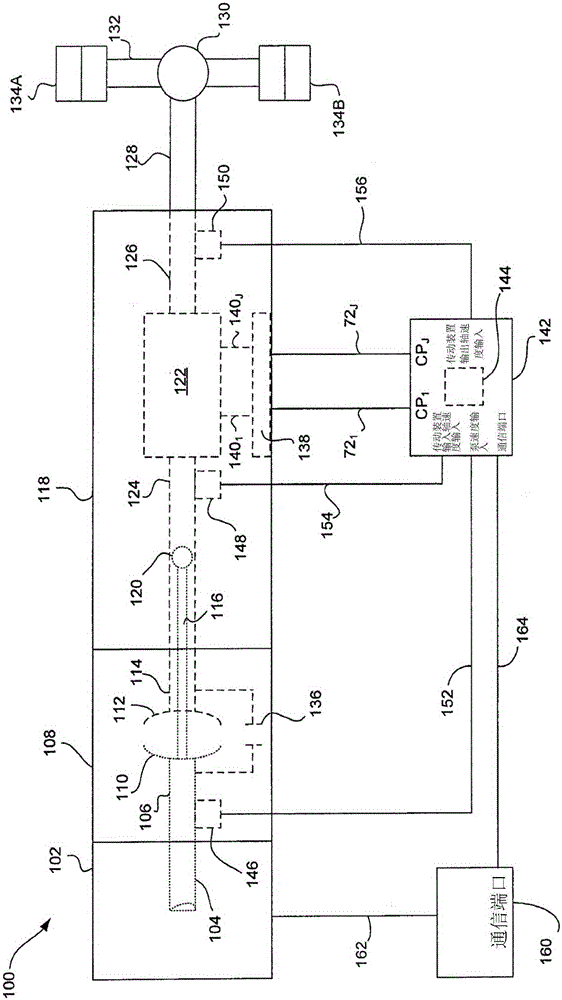

[0034] now refer to figure 1 , a block and schematic diagram of one illustrative embodiment of the vehicle system 100 having the drive unit 102 and the transmission 118 is shown. In the illustrated embodiment, drive unit 102 may include an internal combustion engine, a diesel engine, an electric motor, or other power generating device. The drive unit 102 is configured to rotatably drive an output shaft 104 that is coupled to an input or pump shaft 106 of a conventional torque converter 108 . The input or pump shaft 106 is coupled to an impeller or pump 110 that is rotatably driven by the output shaft 104 of the drive unit 102 . The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com