Polyester bamboo-fiber/original-bamboo-fiber elastic glued cushion

The technology of fiber elasticity and polyester bamboo is applied in the field of polyester bamboo fiber elastic glue-coated soft pad and its preparation field, which can solve the problems of human sleep inhalation hazards, uneven thickness, unfavorable health, etc. The effect of reducing labor costs and reducing noise disturbance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The technical solutions of the present invention will be further explained below in conjunction with the drawings and embodiments, but the following content is not intended to limit the protection scope of the present invention.

[0038] The present embodiment provides a kind of preparation method of polyester bamboo (former) fiber elastic glue-coated cushion, and implementation process is realized by 11 road process equipments, and concrete steps are as follows:

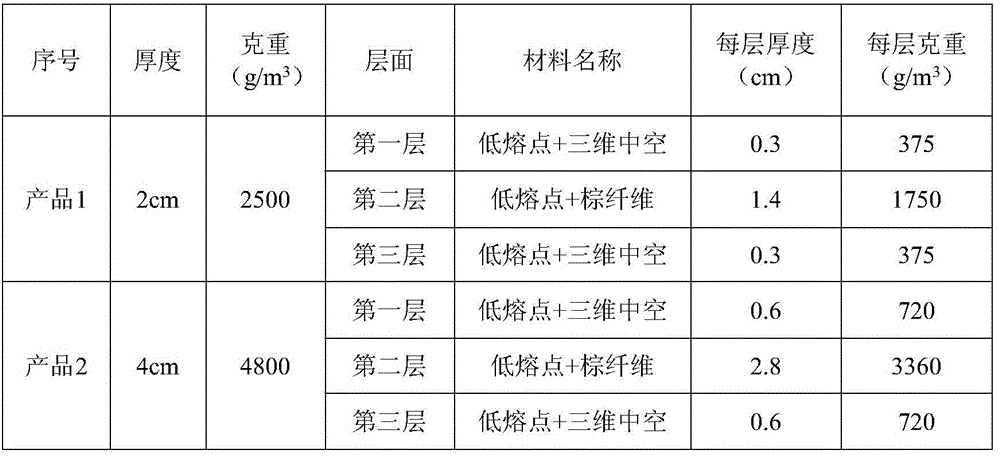

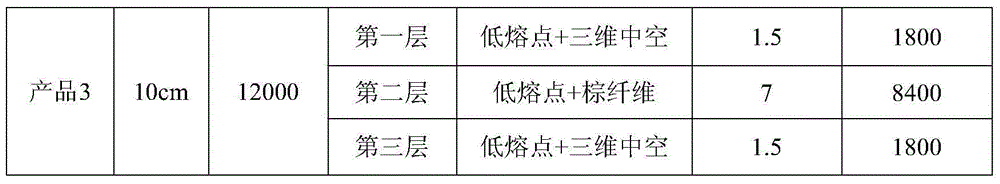

[0039] ①According to the multi-layer material, the upper and lower sides are made of low melting point bi-component skin-core fiber and three-dimensional curled round hollow fiber, and the ingredients are prepared according to the thickness, density and hardness of the material;

[0040] ② Spread the prepared raw materials evenly on the batching machine, and automatically feed according to the equipment instructions;

[0041] ③The pre-opening machine automatically pre-opens after feeding, and conveys accordin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com