A slag breaking device for the bottom of slag gasifier

A technology of slag gasification and gasification furnace, which is applied in the manufacture of combustible gas, petroleum industry, grain processing, etc. It can solve the problems of poor slag discharge of gasifier, clogging of slag outlet, and affecting the normal operation of gasifier, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

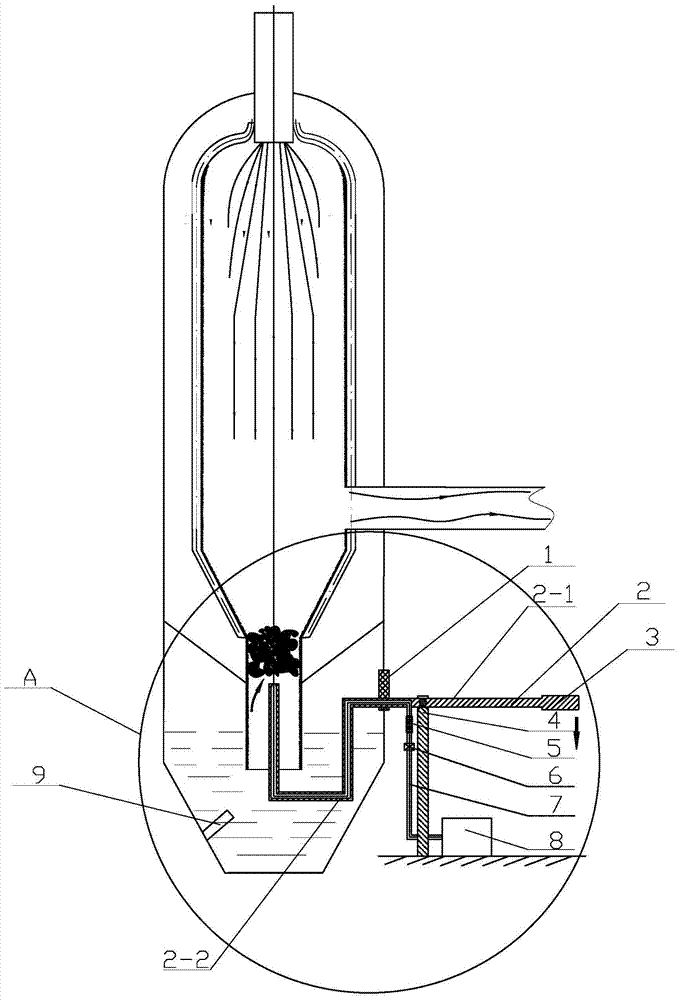

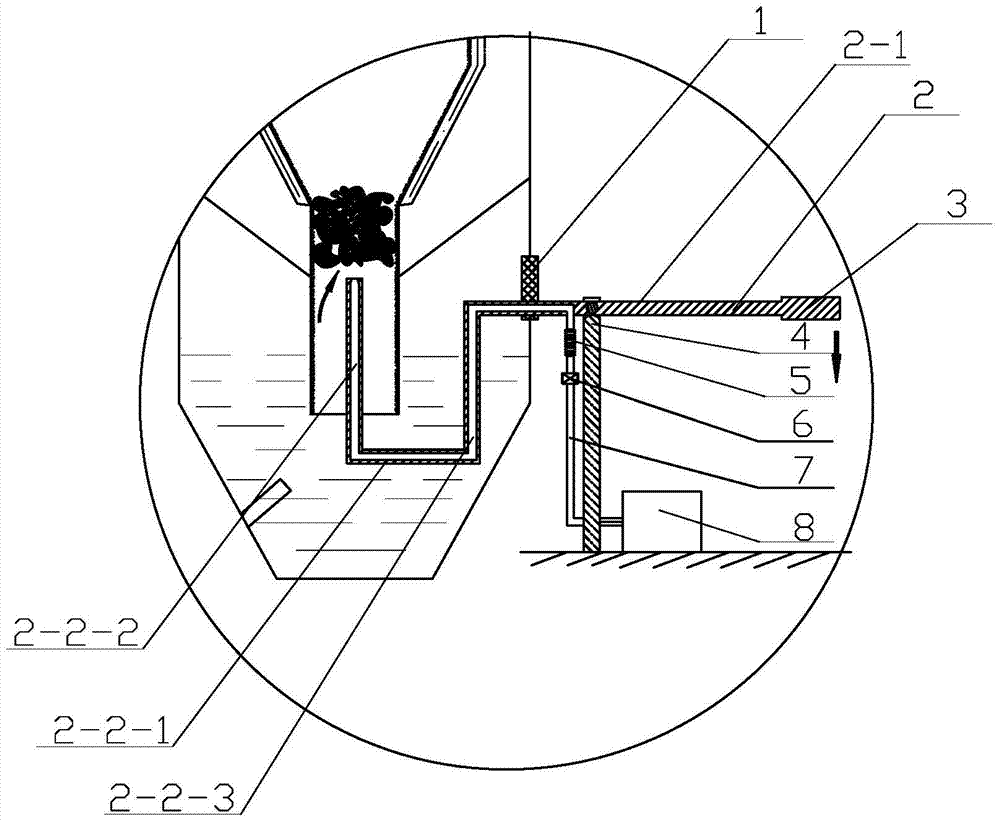

[0011] Specific implementation mode one: combine figure 1 with figure 2 Describe this embodiment, a slag breaking device for the bottom of a slag gasifier in this embodiment includes a flexible sealing device 1, a lever 2, an operating handle 3, a support rod 4, a telescopic rod 5, a flow regulating valve 6, a water supply Pipe 7, water pump 8, and support rod 4 are installed vertically on the ground. Lever 2 is rotatably connected to the upper part of support rod 4. The head end of lever 2 passes through the furnace body of the gasifier and extends into the lower part of the bottom of the gasifier. Inside the tube, the lever 2 is sealed and connected to the gasifier body through a flexible sealing device 1. The end of the lever 2 is provided with an operating handle 3, and a hollow channel is opened from the head end of the lever 2 to the connecting part between the lever 2 and the support rod 4 for water supply. The pipe 7 is airtightly connected with the hollow passage, t...

specific Embodiment approach 2

[0012] Specific implementation mode two: combination figure 1 with figure 2 Describe this embodiment, the lever 2 of this embodiment includes a horizontal part 2-1 and a bending part 2-2, the horizontal part 2-1 is rotatably connected with the lever 2, the bending part 2-2 and the horizontal part 2-1 The left ends are joined and made into one piece. In this way, the bending part 2-2 is provided to facilitate the lever to be inserted into the furnace body, so as to realize the crushing of the slag in the furnace body. Other compositions and connections are the same as in the first embodiment.

specific Embodiment approach 3

[0013] Specific implementation mode three: combination figure 1 with figure 2 To illustrate this embodiment, the bending part 2-2 of this embodiment includes a horizontal rod 2-2-1, a first vertical rod 2-2-2 and a second vertical rod 2-2-3, and the first vertical rod 2-2-3. A vertical rod 2-2-2 and a second vertical rod 2-2-3 are relatively vertically arranged, and the first vertical rod 2-2-2 and the second vertical rod 2-2- 3 are connected by horizontal rods. Such setting is convenient to adapt to the requirements of the downcomer structure of the furnace body, and at the same time, it is convenient to adjust the movement direction of the first vertical rod 2-2-2, so that the cooling water output by the first vertical rod 2-2-2 can be poured On the slag, and after the slag is broken, it can also provide enough falling space for the broken slag. Other compositions and connections are the same as those in the second embodiment.

[0014] Specific implementation mode four:...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com