Multi-angle steel plate drilling device

A drilling device, multi-angle technology, applied in the driving device, boring/drilling, drilling/drilling equipment, etc., can solve the problems of high cost, high price of numerical control equipment, and complicated operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

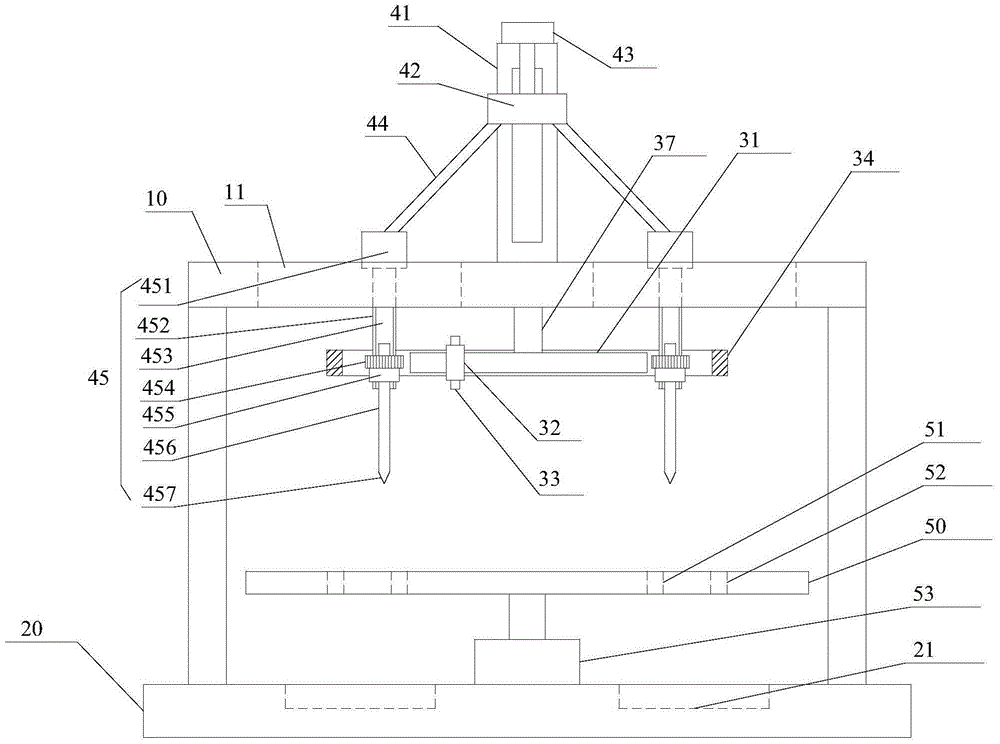

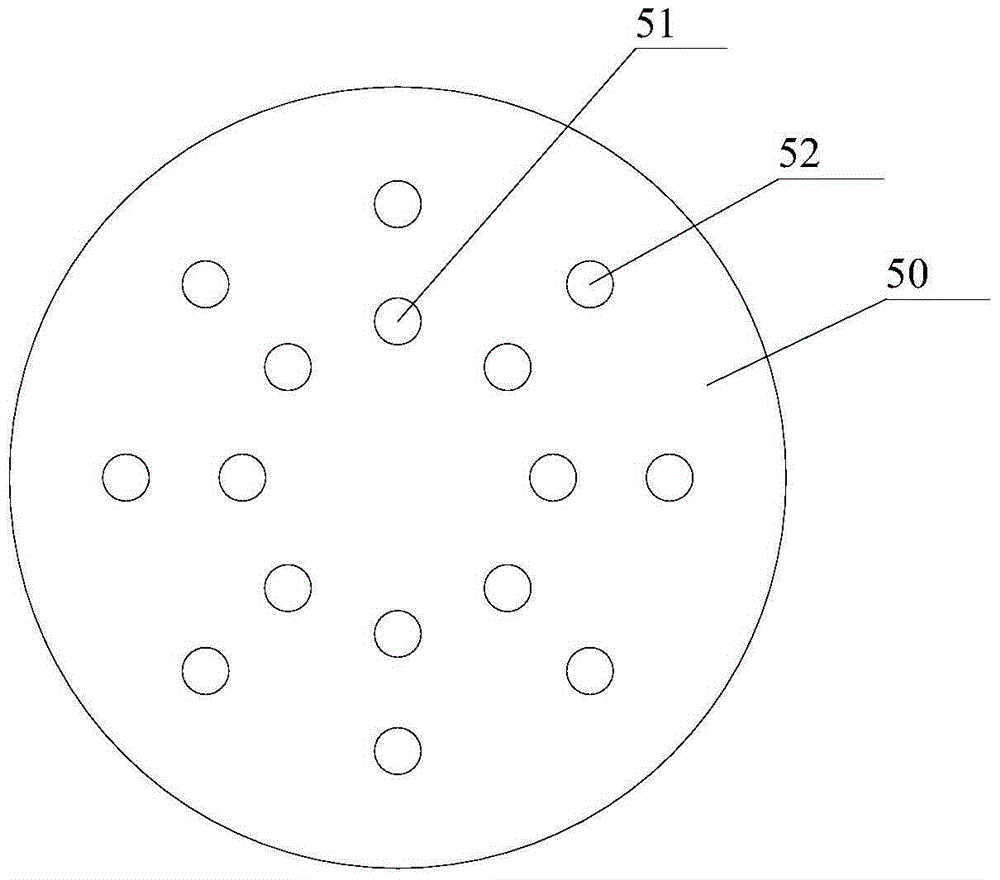

[0023] refer to figure 1 , figure 2 , image 3 , the present invention proposes a multi-angle steel plate drilling device, including a first support 10, a second support 20, a driving mechanism, a drilling mechanism for drilling a steel plate, a support plate 50 for supporting a steel plate, a second drive means 53, wherein:

[0024] A working area is formed between the first support 10 and the second support 20, and the support plate 50 and the driving mechanism are located in the working area.

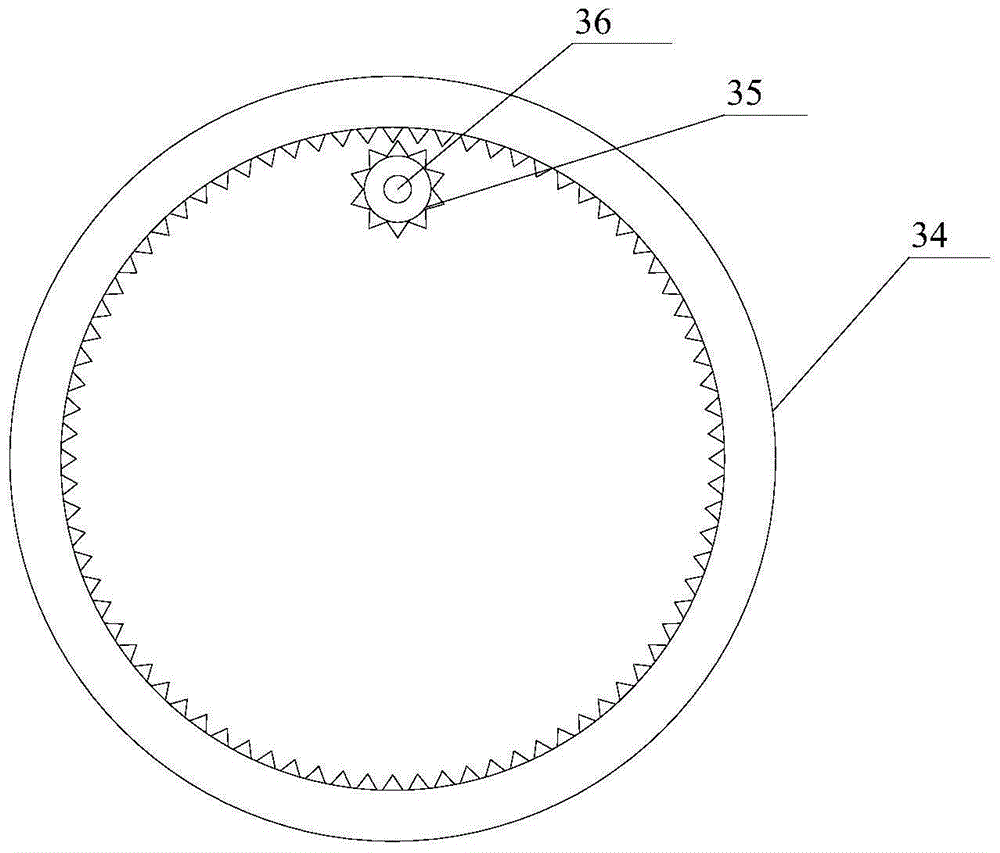

[0025] The driving mechanism includes a first gear 31, a first rotating shaft 33, a second gear 32, a third gear 35, a second rotating shaft 36, and an internal gear 34. The first gear 31 is rotationally connected with the first bracket 10 through a connecting rod 37, The first rotating shaft 33 is fixedly connected with the second gear 32, and the second gear 32 meshes with the first gear 31; the outer circumference of the first gear 31 is coaxially provided with the internal ge...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap