Drawer type chip removing water tank

A drawer type, water tank technology, applied in metal processing machinery parts, maintenance and safety accessories, metal processing equipment, etc., can solve the problems affecting the precision of workpiece processing, and achieve the effect of convenient operation, labor saving and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

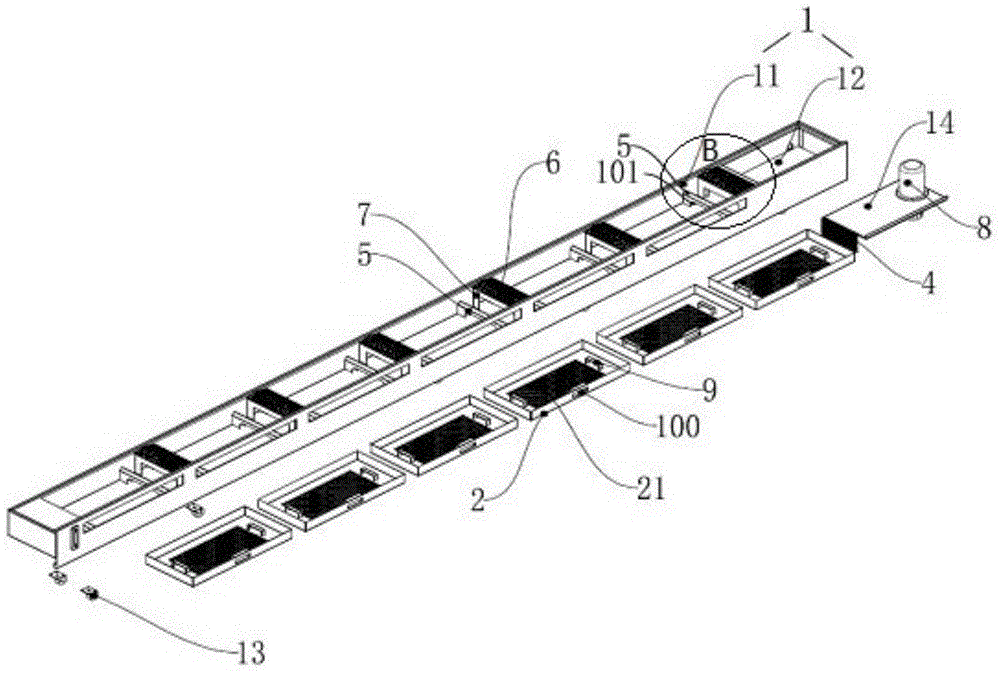

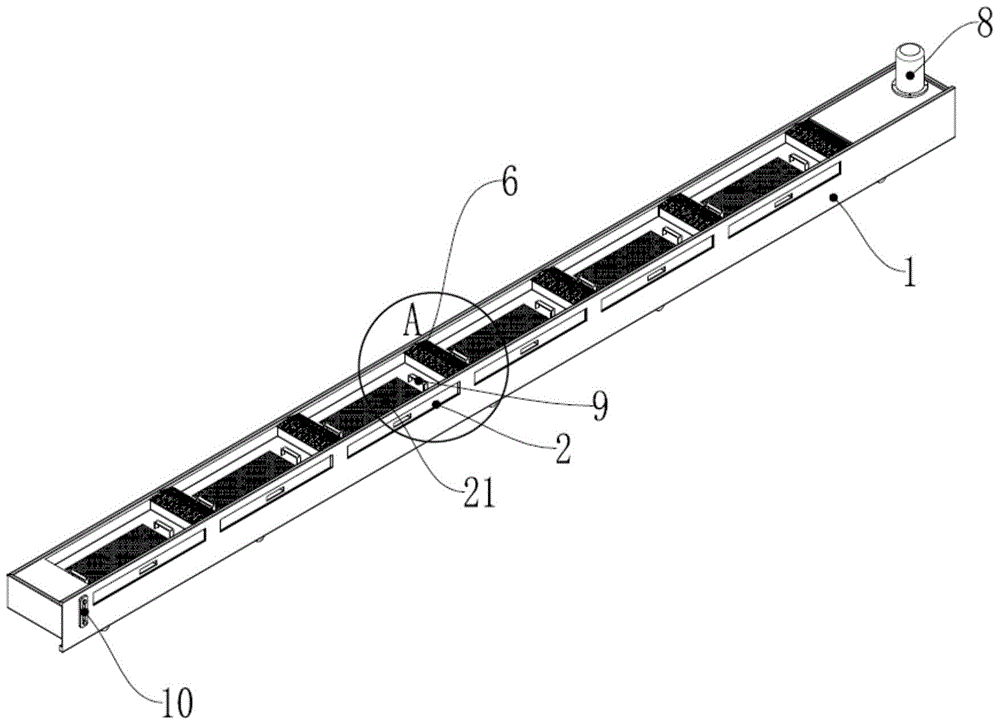

[0024] like figure 1 and figure 2 A drawer-type chip removal water tank is shown, including a box body 1 and a plurality of chip trays 2;

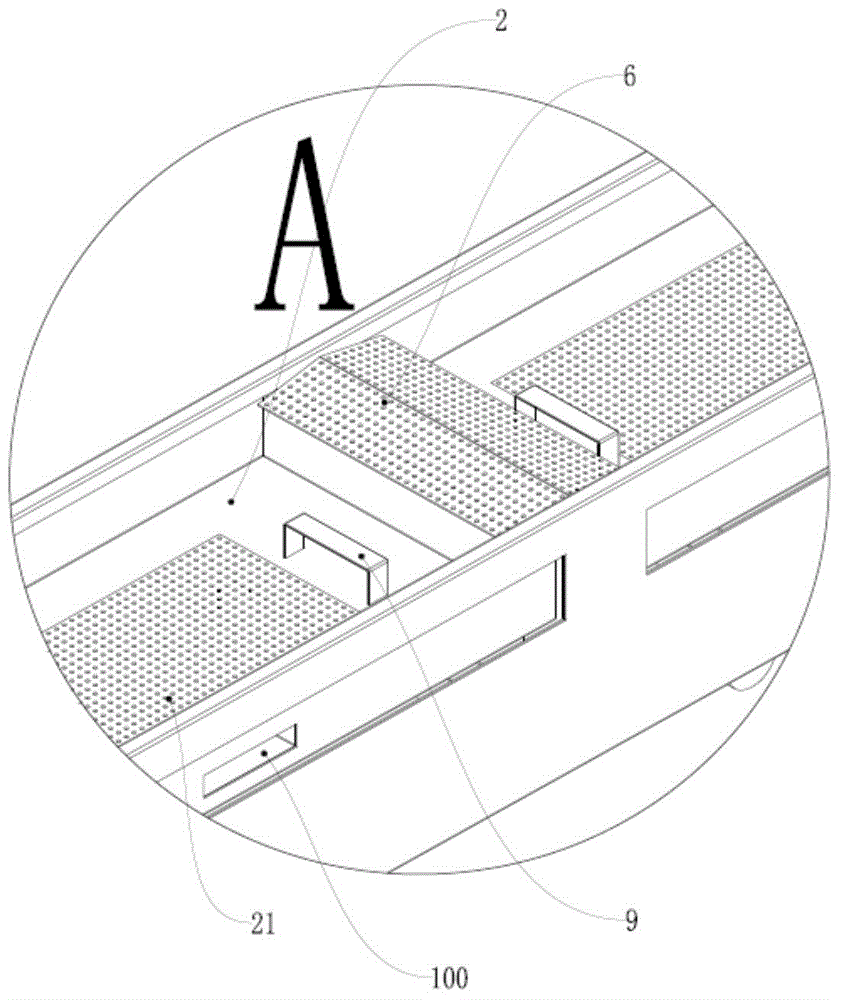

[0025] Described box body 1 is provided with filter net plate 4, and described filter net plate 4 is placed vertically, and described box body 1 is divided into guide dust case lattice 11 and filter case lattice 12; One of described dust guide case lattice 11 The side is provided with a plurality of chip receiving trays 2 that match the chip receiving tray 3; the inside of the chip guide box 11 is provided with a support frame 5, and the support frame 5 is an inverted U-shaped structure 5; The upper end of the support frame 5 is inclined toward the direction of the chip receiving tray 2; the chip receiving tray 2 is inserted into the chip guide box 11 through...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com