Scrap iron trolley

A technology of trolleys and iron filings, which is applied to trolleys, motor vehicles, multi-axis trolleys, etc., can solve the problems of inconvenient collection and transportation of iron filings, and the impact on the production environment, so as to achieve the effects of preventing safety accidents, facilitating transportation and cleaning, and ensuring the production environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

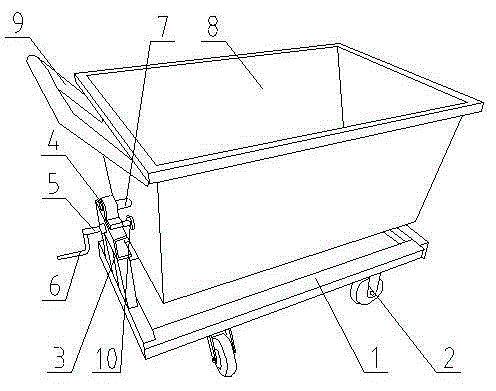

[0020] see figure 1 , a chip trolley according to the present invention, which includes a supporting frame 1, a plurality of moving rollers 2 are arranged at the bottom of the supporting frame 1, brackets 3 are arranged on the left and right sides of the supporting frame 1, and bearings are arranged on the top of the supporting frame 3 Seat 4, the left side bracket 3 is equipped with a limit screw 5 up and down, the limit screw 5 is located below the bearing seat 4, and a collection box 8 is arranged between the left and right side brackets 3, and the collection box 8 Rotating shafts 7 are arranged on the left and right sides, and a limiting hole 10 is arranged under the rotating shaft 7. The rotating shaft 7 is supported on the bearing seat 4, and the position of the limiting screw 5 corresponds to the position of the limiting hole 10. A handle 6 is provided at the outer end of the limiting screw 5 .

[0021] A push handle 9 is provided on the left side of the collection box...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com