Powdery material arch breaking system used in energy-saving and environment-friendly warehousing equipment

A powdery material, energy-saving and environmentally friendly technology, applied in the field of powdery material arch breaking system and arch breaking system, can solve problems such as unreasonable layout of fluidization rods, achieve the effect of improving work efficiency, solving arching, and outstanding effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

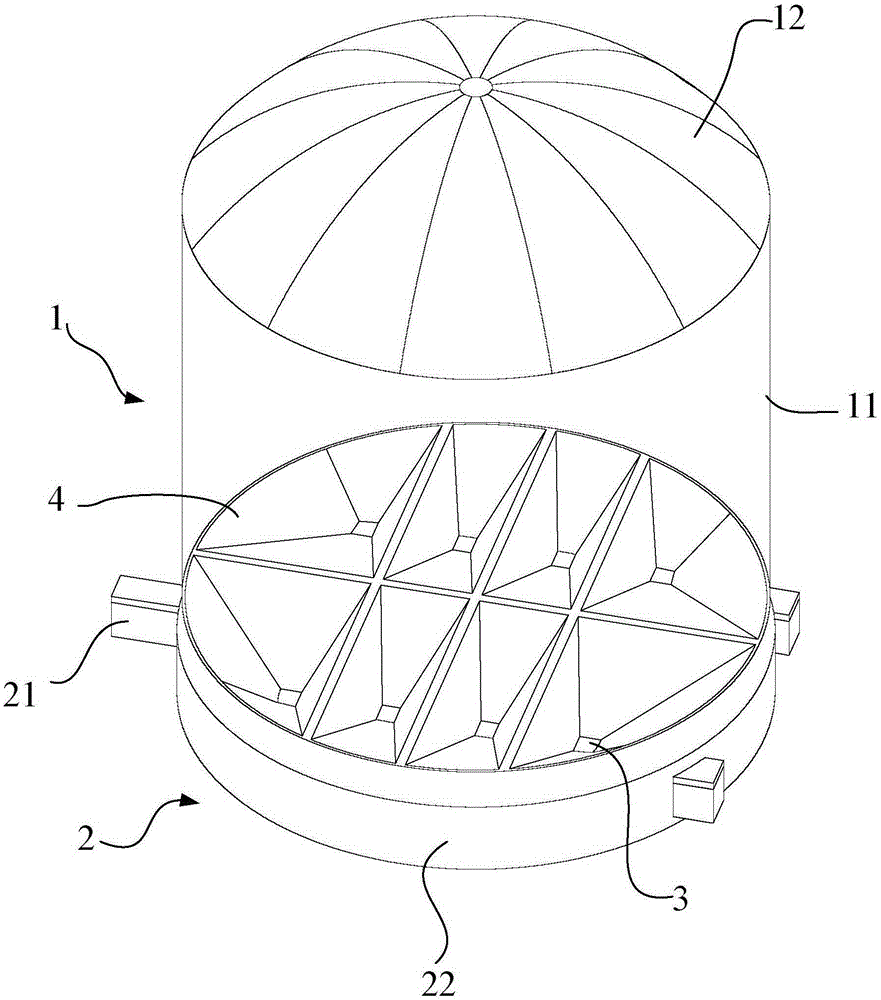

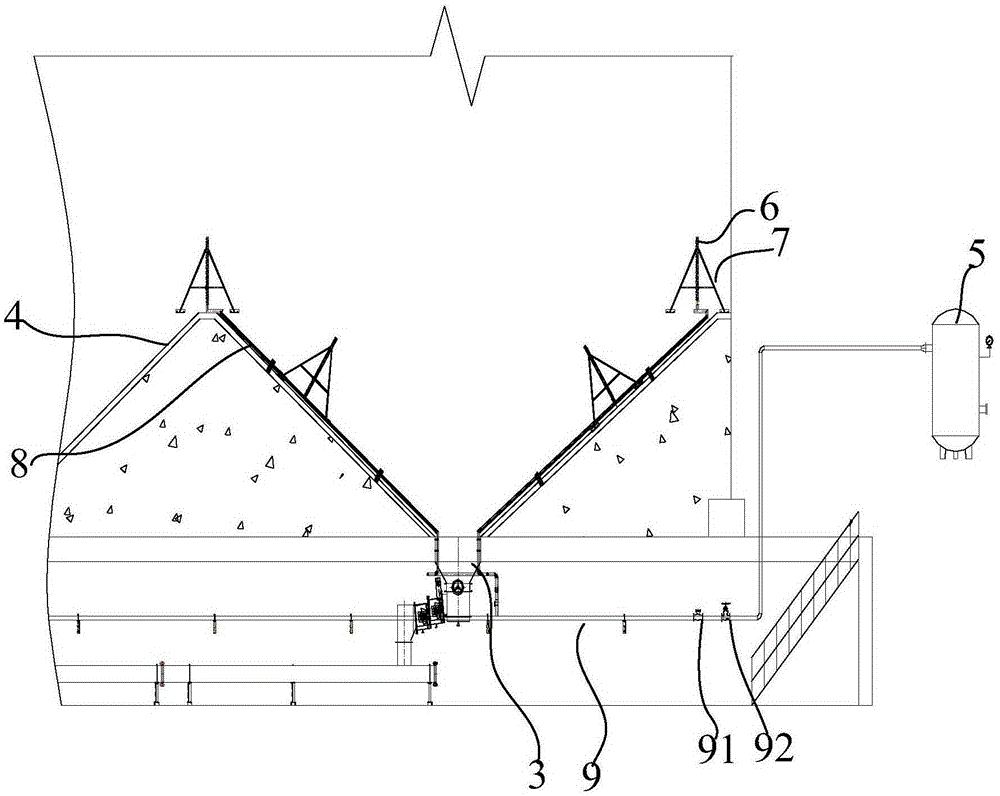

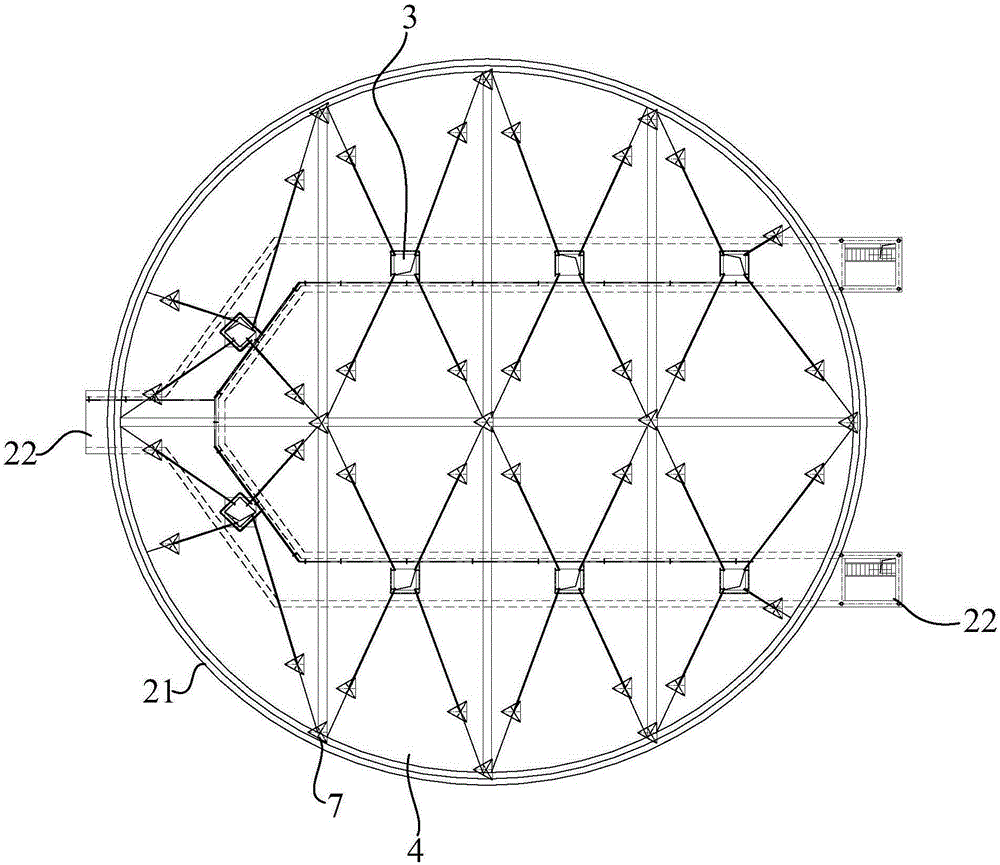

[0029] Example 1, such as figure 1 , figure 2 , image 3 As shown, this embodiment provides an arch-breaking system for powdery materials used in energy-saving and environmentally-friendly storage equipment, including a steel plate warehouse, which includes a silo body 1 and an annular foundation 2 arranged below the silo body 1, The shape of the silo body 1 is cylindrical. The silo body 1 includes a cylinder body 11 and a silo roof 12 on the top of the cylinder body 11. A discharge port 3 is arranged at the bottom of the cylinder body 11, and a discharge port 3 is arranged around the discharge port 3. There is a material guide cone 4, and the annular foundation 2 includes an annular pouring 21 for fixing the silo body 1 and a discharge corridor 22 arranged in the annular pouring 21 to cooperate with the discharge port 3. The above descriptions are all references to the existing Steel plate warehouses are described, there may be slight differences, but they are roughly simi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com