Self-cleaning negative pressure blower

A negative pressure fan and self-cleaning technology, which is applied in the direction of mechanical equipment, machine/engine, liquid fuel engine, etc., can solve the problems of frequent cleaning of the fan, heavy workload, and the failure of the fan to work smoothly, so as to ensure work efficiency and efficiency guarantee Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

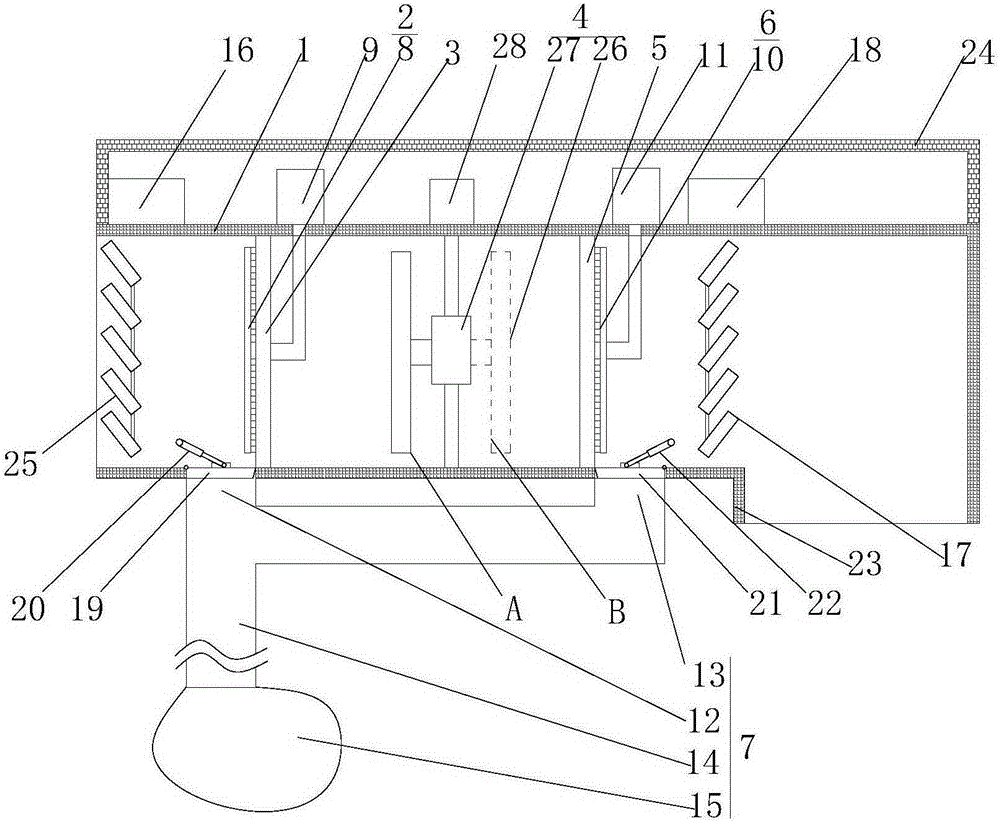

[0017] Such as figure 1 as shown, figure 1 It is a schematic structural diagram of a self-cleaning negative pressure fan proposed by the present invention.

[0018] refer to figure 1 , a self-cleaning negative pressure fan proposed by the present invention includes a first cylindrical shell 1, a first cleaning assembly 2, a first filter screen 3, an exhaust assembly 4, a second filter screen 5, a second cleaning assembly 6 and dirt collection assembly 7;

[0019] The first axial end of the first cylindrical shell 1 is provided with an indoor inlet and outlet, and the second end is an outdoor inlet and outlet. The first cleaning assembly 2, the first filter screen 3, the exhaust assembly 4, and the second filter screen 5 1. The second cleaning assembly 6 is all arranged in the cavity of the first cylindrical housing 1, and is arranged sequentially along the first end to the second end of the first cylindrical housing 1; the exhaust assembly 4 includes a fan blade 26 and a mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com