Suspended swing arm contourgraph for ultra-large diameter surface shape detection

A swing arm profiler and surface shape detection technology, applied in the direction of instruments, measuring devices, etc., can solve the problems of reduced detection accuracy, excessive arm length, etc., and achieve the effects of improving stability, realizing detection, and reducing measurement uncertainty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

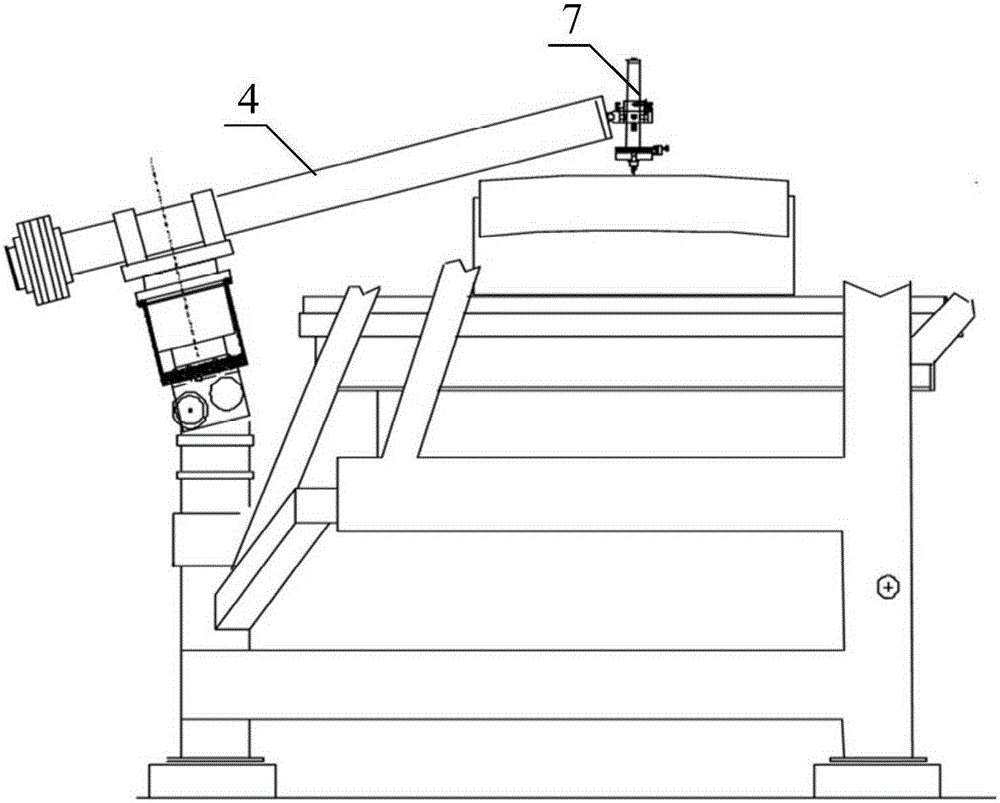

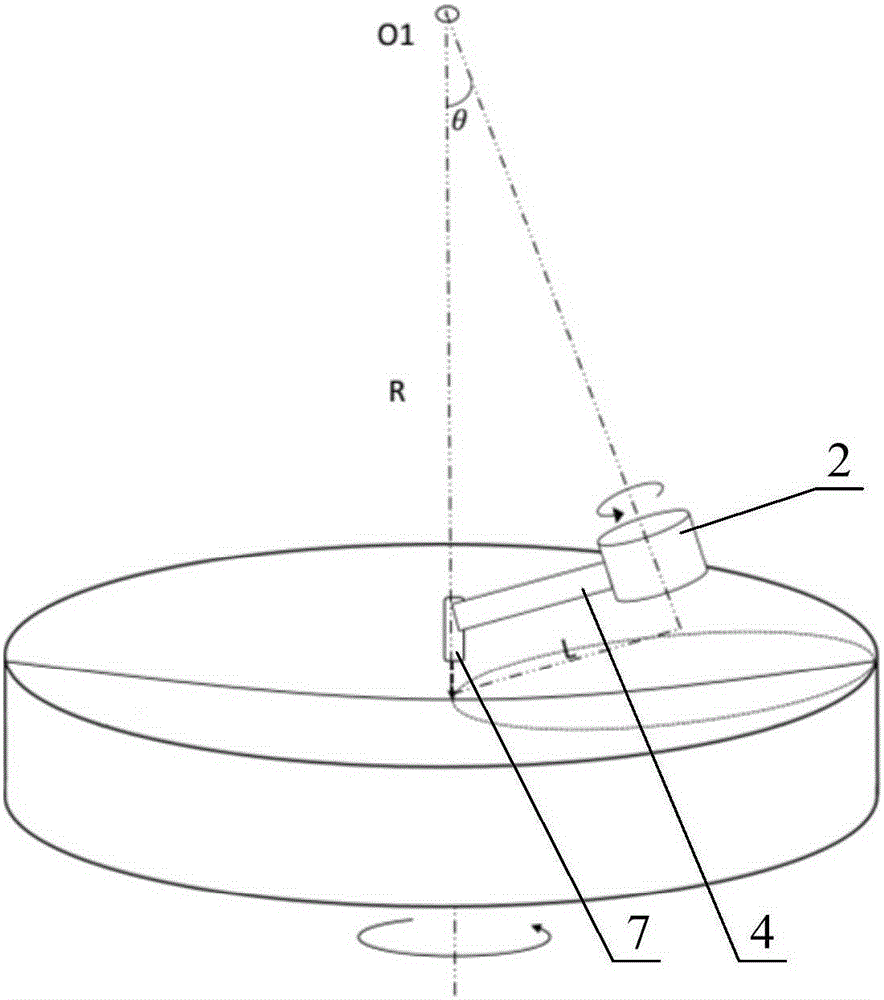

[0040] See attached image 3 , attached Figure 4 And attached Figure 5 , the suspended arm swing arm profiler for ultra-large diameter surface shape detection of the present invention includes a connecting piece A1, an air bearing turntable 2, a connecting piece B3, a measuring arm 4, a counterweight 5, a connecting piece C6 and a displacement sensor 7;

[0041] The air-floating turntable 2 is suspended and connected to the suspension device 8 through the connecting piece A1; the measuring arm 4 is fixed to the air-floating turntable 2 through the connecting piece B3; one end of the measuring arm 4 is fixed to the displacement sensor 7 through the connecting piece C6 The measuring head; the counterweight 5 is used to be fixed on the other end of the measuring arm 4 relative to the measuring head of the displacement sensor 7, so as to realize the bala...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com