Coaxial three-reflection telescope objective for planar view field without secondary blocking

A coaxial three-mirror and telescopic objective lens technology is applied in the field of optical imaging, which can solve the problems of large volume and secondary blocking, and achieve the effects of strong light-gathering ability, wide adaptable temperature range and good stray light suppression performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

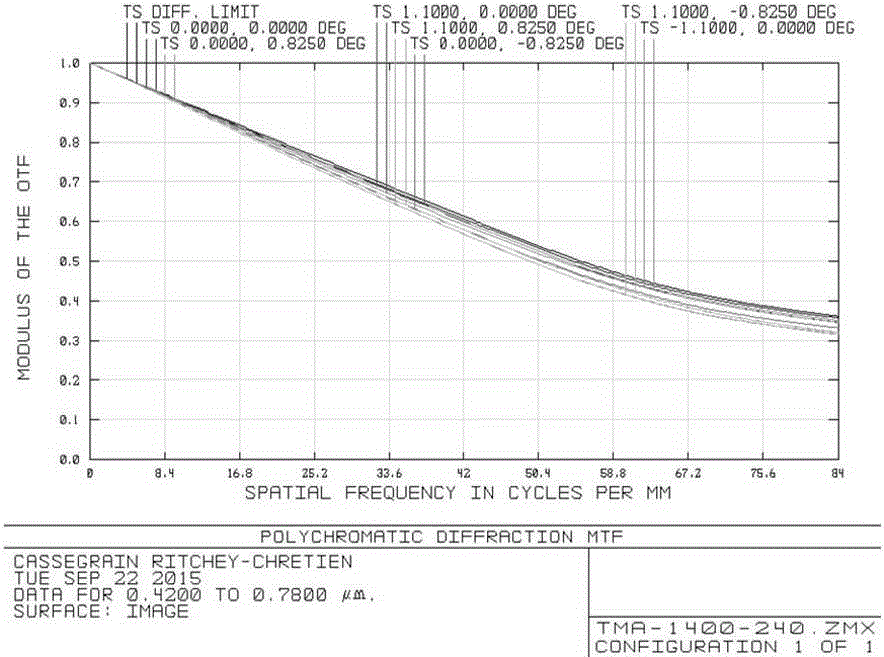

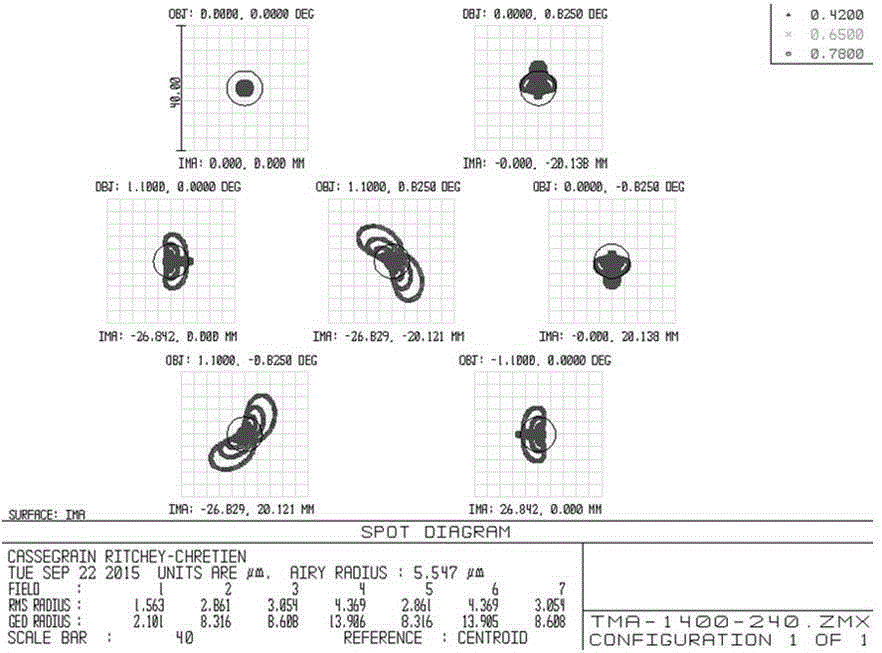

[0028] The technical solution of this embodiment is to provide a coaxial triple-mirror telescopic objective lens with no secondary obscuring surface field of view. The design parameters are: focal length 1400mm, full field of view angle 2.2°×1.65°, F number 7, working band 0.42μm ~0.78 μm.

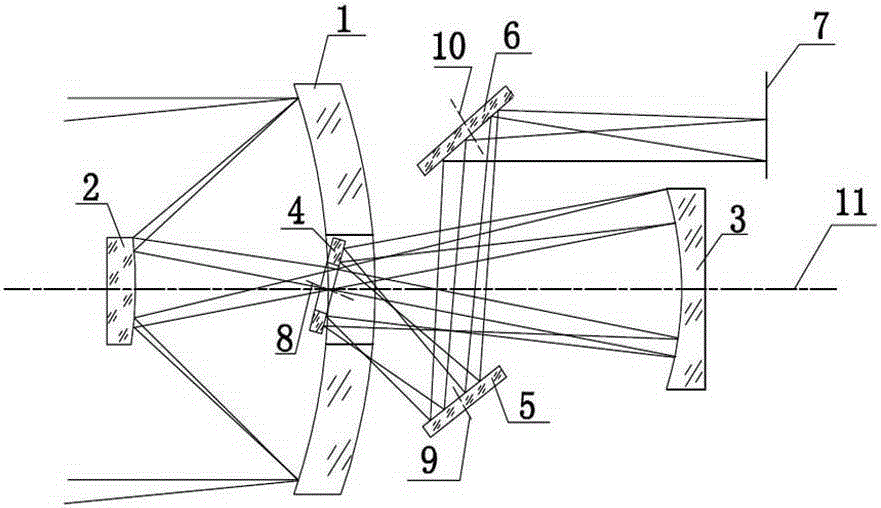

[0029] See attached figure 1 , which is the optical path diagram of the telescopic objective provided in this embodiment. The primary mirror 1, the secondary mirror 2 and the third mirror 3 are coaxial, the aperture stop is located on the primary mirror 1, and the deflection mirror 4 is located between the secondary mirror 2 and the third mirror 3. After the incident light is reflected by the primary mirror 1 and the secondary mirror 2 in turn, a real image is formed between the secondary mirror 1 and the third mirror 3, and the reflected light passes through the central hole of the deflection mirror 4 without obstruction, and the three mirrors 3 pair a real image For relay imaging, the ...

Embodiment 2

[0038] This embodiment adopts the index requirements of Embodiment 1, that is, the focal length is 1400 mm, the full field of view is 2.2°×1.65°, the F number is 7, and the working band is 0.42 μm to 0.78 μm.

[0039] See attached Figure 6 , which is the imaging optical path diagram of the coaxial triple mirror telescopic objective lens provided in this embodiment. The primary mirror 1, the secondary mirror 2 and the third mirror 3 are coaxial, the aperture stop is located on the primary mirror 1, and the deflection mirror 4 is located between the secondary mirror 2 and the third mirror 3. After the incident light is reflected by the primary mirror 1 and the secondary mirror 2 in turn, a real image is formed between the secondary mirror 2 and the third mirror 3, and the reflected light passes through the center hole of the deflection mirror 4 without obstruction, and the three mirrors 3 pair a real image For relay imaging, the reflected light is incident on the clear apertur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com