Novel planar Gunn diode and preparation method thereof

A Gunn diode and planar technology, which is applied in the field of new planar Gunn diode and its preparation, can solve the problems of lower reliability, difficult working frequency, unfavorable application, etc., and achieve the goal of improving device performance, increasing transmission frequency, and reducing mutual interference Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

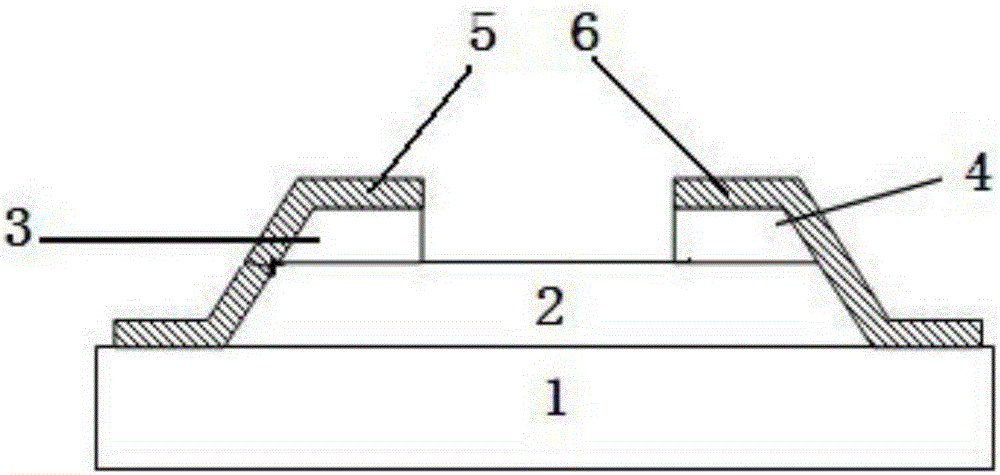

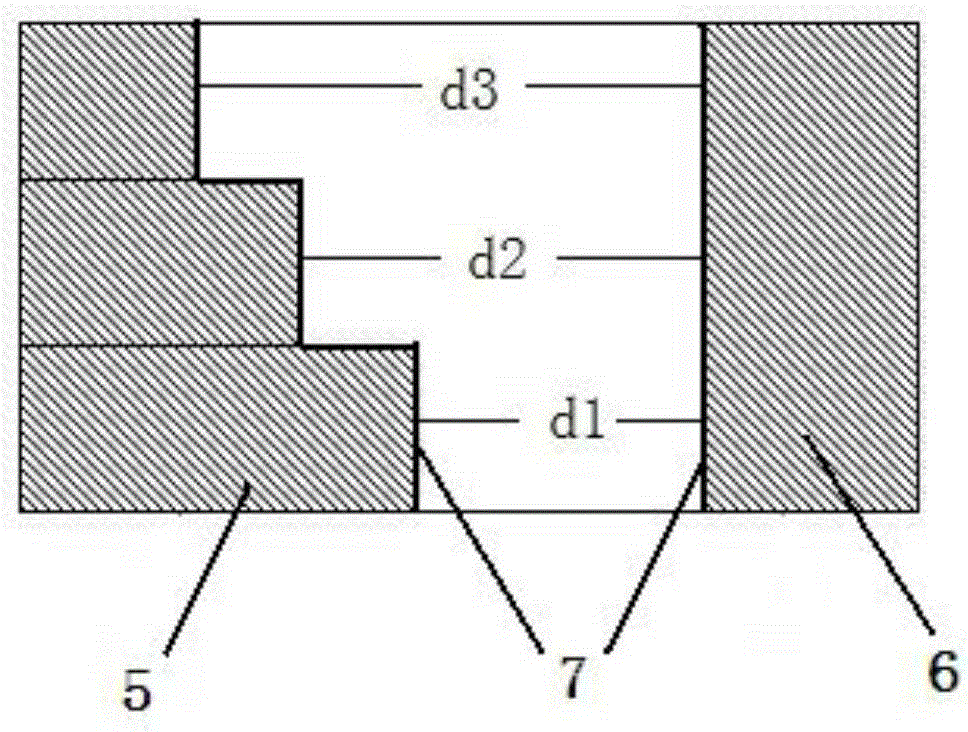

[0045] A new type of planar Gunn diode, comprising: an insulating substrate 1, a channel layer 2, and a first electrode part and a second electrode part arranged on the channel layer 2 from bottom to top, the first At least one of the electrode part, the second electrode part, and the channel formed by the first electrode part and the second electrode part is integrated, and the electrode edge 7 of the first electrode part is connected to the second electrode Part of the electrode edges 7 are not parallel.

[0046] The electrode edge 7 of the first electrode part refers to the intersection line between the surface of the first electrode part opposite to the second electrode part and the channel layer 2. Similarly, the second electrode part The electrode edge 7 refers to the intersection line between the surface of the second electrode portion opposite to the first electrode portion and the channel layer 2 .

[0047] The advantage of the design here is that the electrode edge ...

Embodiment 2

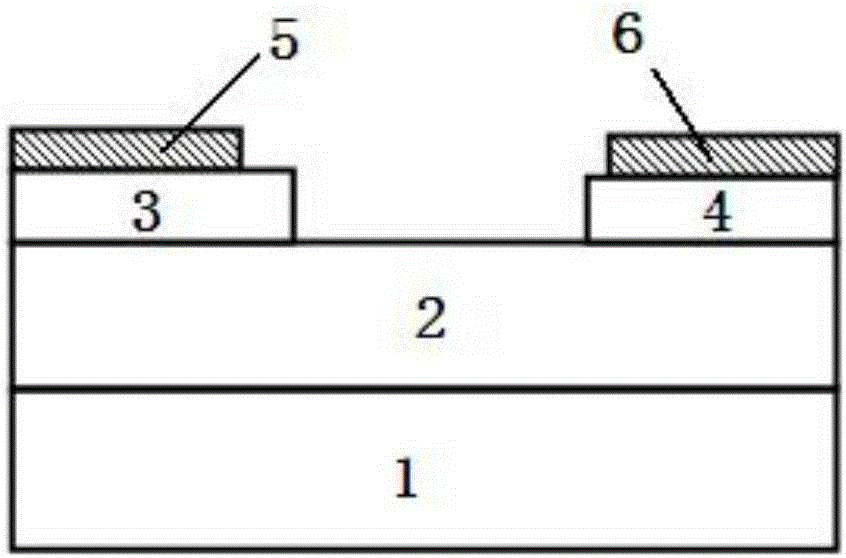

[0056] According to a new type of planar Gunn diode described in Embodiment 1, the difference is that the first electrode part includes a first electrode 5 and a first capping layer 3, and the first capping layer 3 is arranged on the first Between the electrode 5 and the channel layer 2, the second electrode part includes a second electrode 6 and a second cap layer 4, and the second cap layer 4 is arranged between the second electrode 6 and the channel layer. Between layers 2, the first electrode 5 does not cover the first capping layer 3, and the second electrode 6 does not cover the second capping layer 4, as image 3 shown.

Embodiment 3

[0058] According to a new type of planar Gunn diode described in Embodiment 1, the difference is that the first electrode part includes a first electrode 5 and a first capping layer 3, and the first capping layer 3 is arranged on the first Between the electrode 5 and the channel layer 2, the second electrode part includes a second electrode 6 and a second cap layer 4, and the second cap layer 4 is arranged between the second electrode and the channel layer 6. Between layers 2, the first electrode 5 does not cover the first capping layer 3, and the second electrode 6 covers the second capping layer 4 to contact the channel layer 2, as Figure 4 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com