Ejector pin structure of laminating machine

A laminator and thimble technology, applied in lamination, lamination devices, layered products, etc., can solve problems such as inconsistent cross-linking degrees, achieve consistent EVA cross-linking degrees, and ensure consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

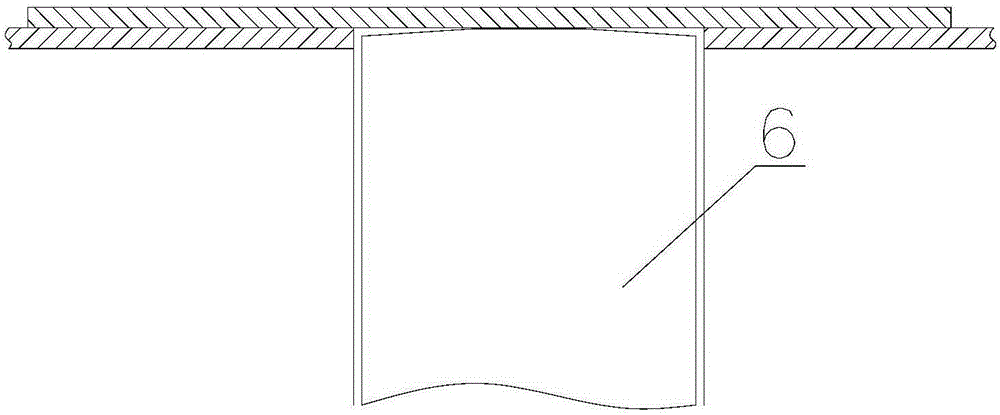

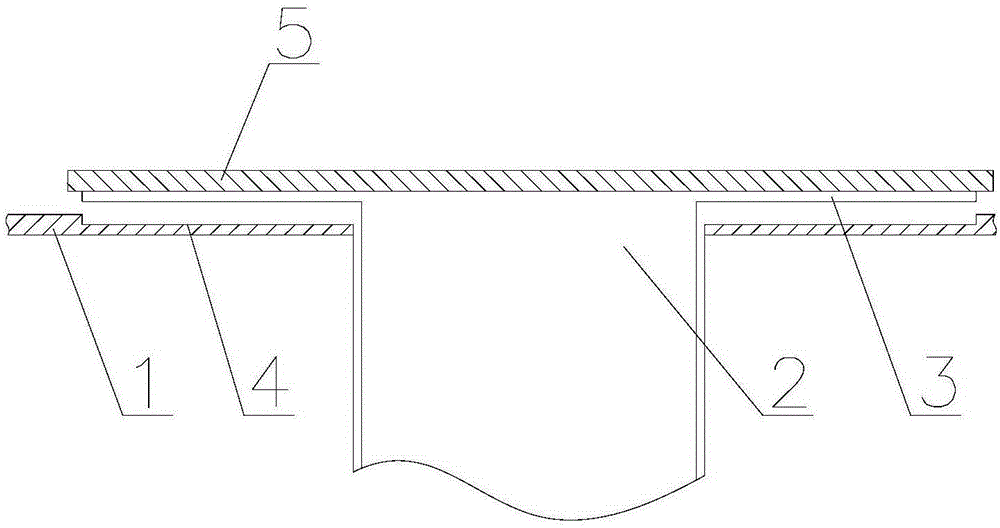

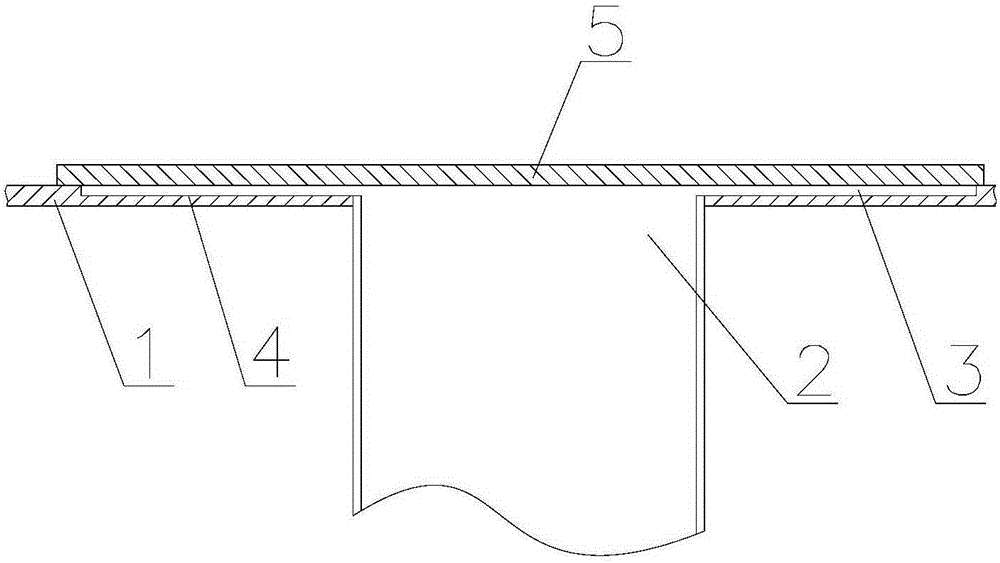

[0019] Such as Figure 2-4 As shown, a thimble structure of a laminator, the laminator has a heating plate 1, a guide hole is provided on the heating plate 1, the upper surface of the heating plate 1 is a plane, and the thimble structure includes a guide hole The matching needle body 2 and the platform 3 covered on the top of the needle body 2, the upper surface of the platform 3 is a plane, the needle body 2 is inserted in the guide hole, and the heating plate 1 is located on the The part directly below the platform 3 is provided with a depression 4 that matches the platform 3. When the lower surface of the platform 3 is in contact with the bottom surface of the depression 4, the upper surface of the platform 3 is flush with the upper surface of the heating plate 1. , to ensure the consistency of heat transfer, the material of the needle body 2 and the platform 3 is the same as that of the heating plate 1, the needle body 2 is cylindrical, and the platform 3 is cylindrical. I...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com