Shape memory material with fiber structure and preparation method of shape memory material

A memory material and fiber structure technology, applied in fiber processing, single-component polyurethane artificial filament, conjugated synthetic polymer artificial filament, etc., can solve the limitations of research and application, no microstructure construction, surface microstructure damage and other issues to achieve the effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

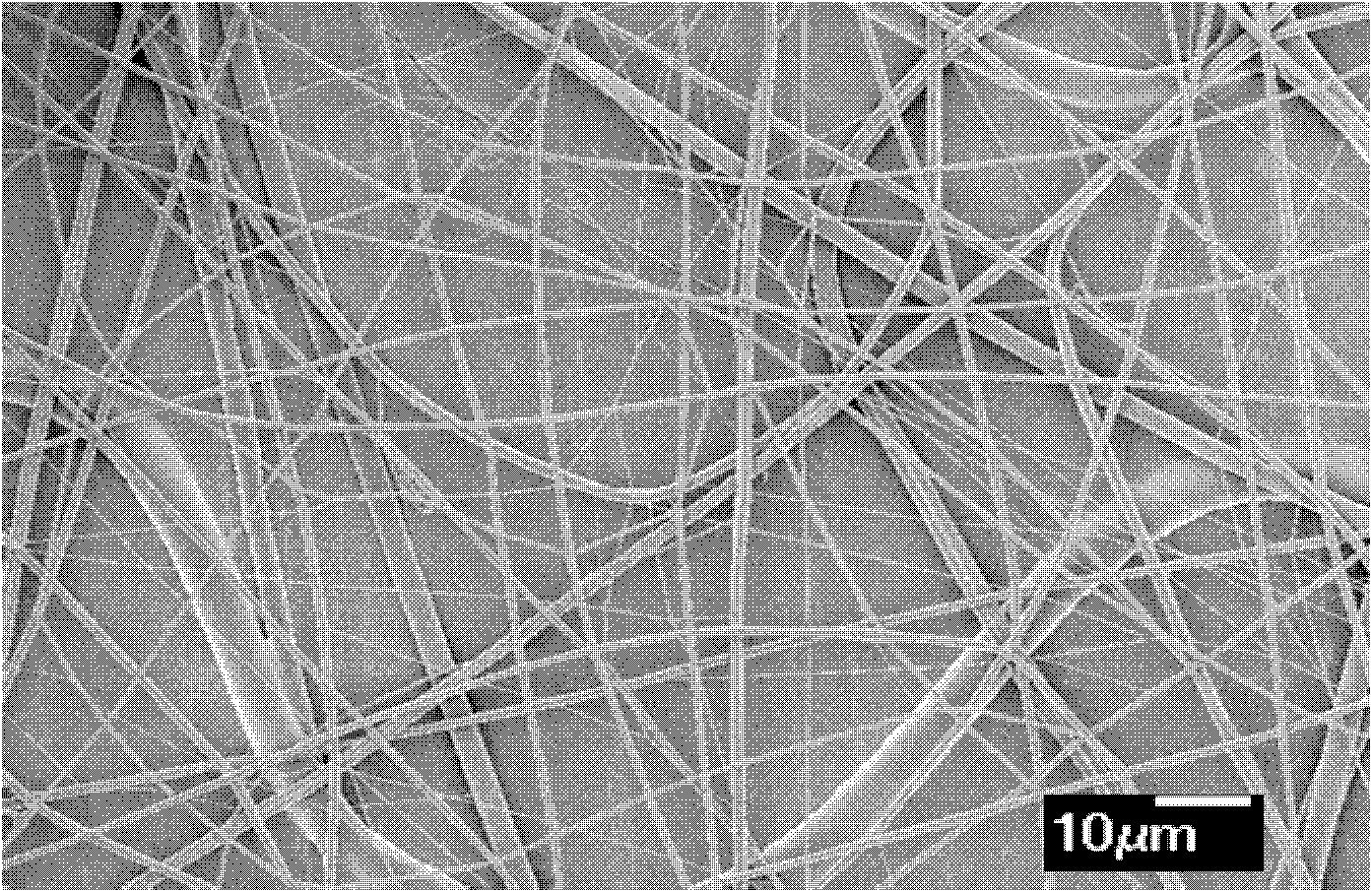

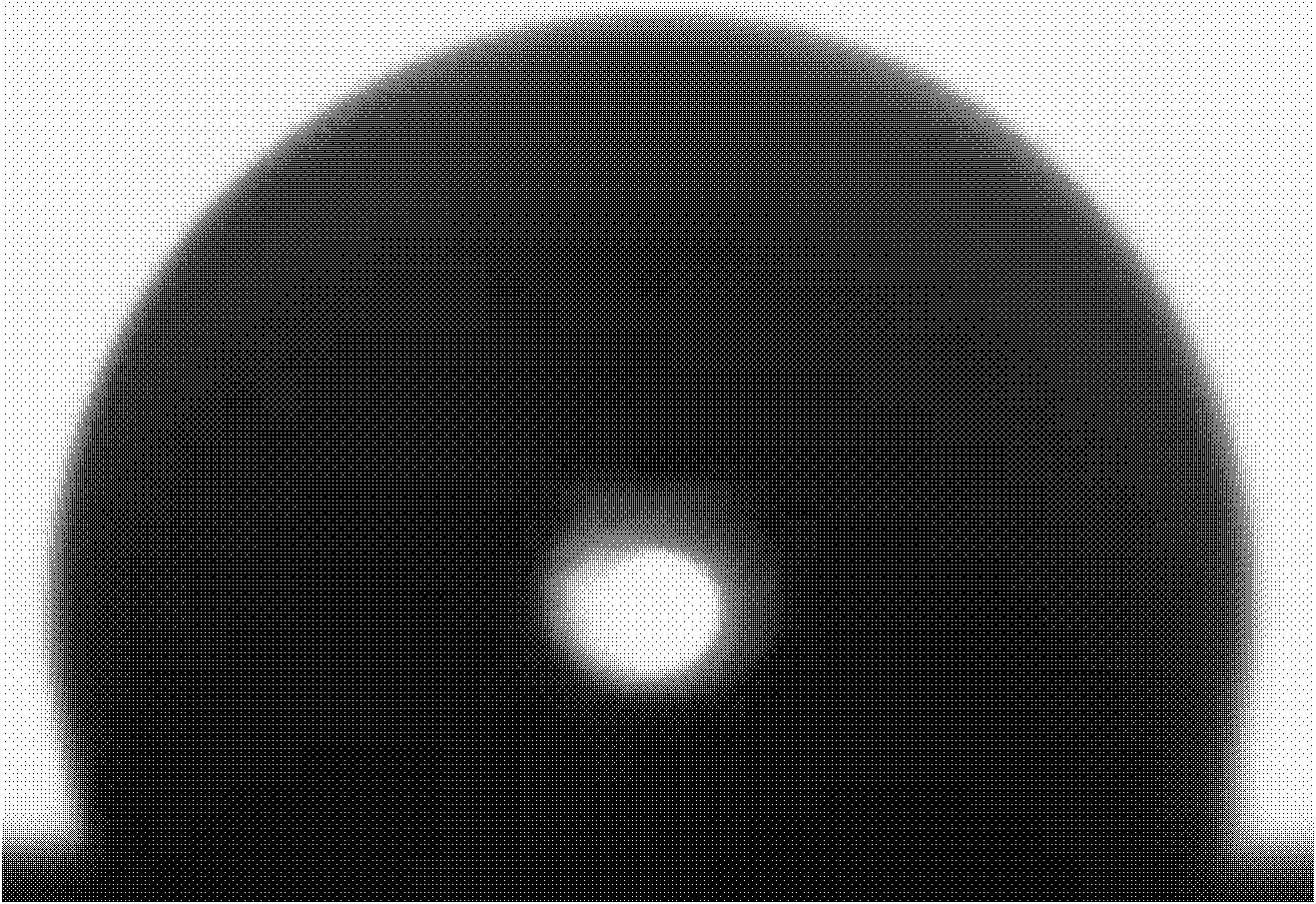

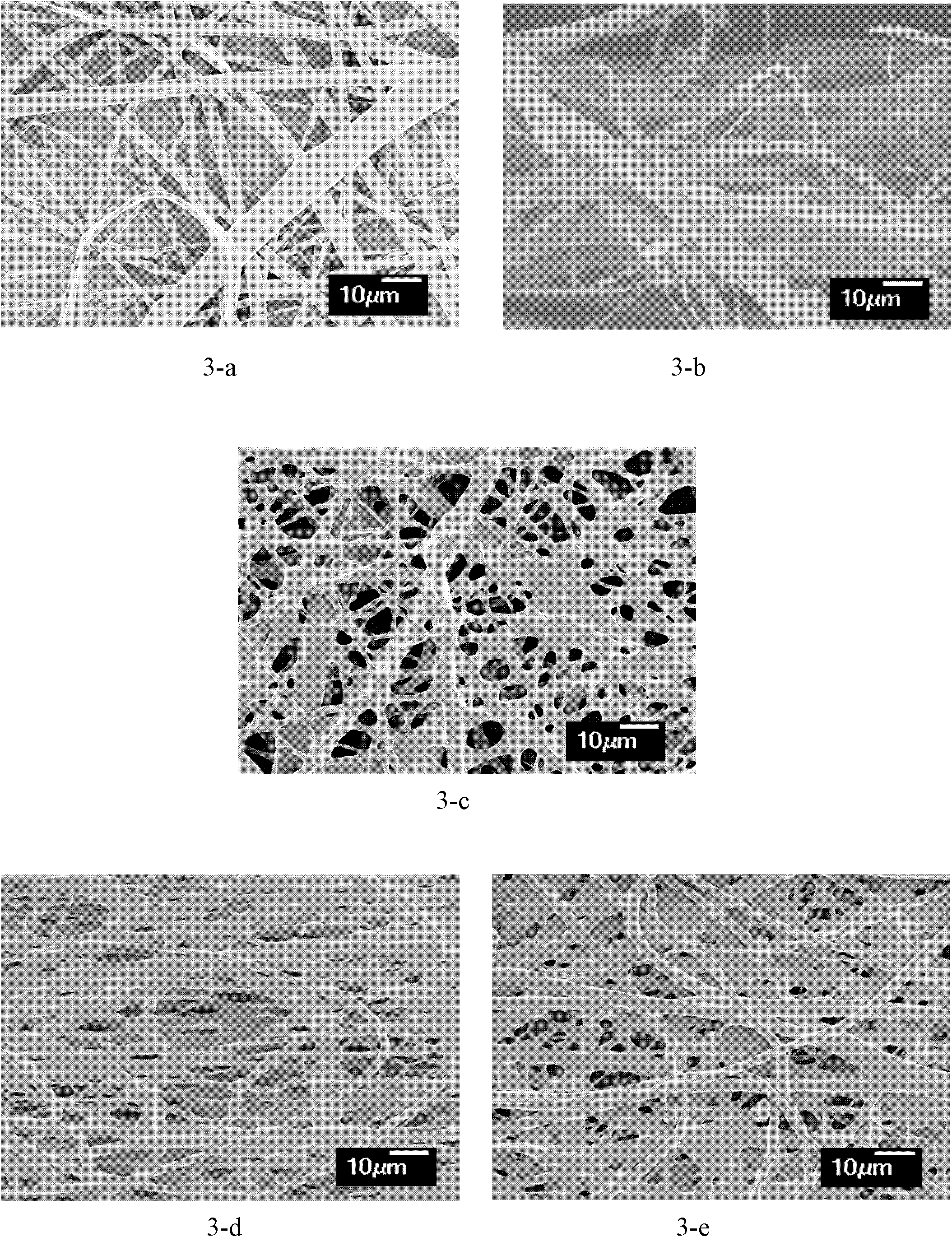

Method used

Image

Examples

Embodiment 1

[0049] 1) in N 2 Under protection, add HDI to a three-necked flask equipped with a stirrer, put the three-necked flask in an oil bath and heat it to 70°C, and then add the dehydrated N,N-dimethylformamide with a mass fraction of 50% PDA solution, mechanically stirred and reacted for 1 hour to prepare a HDI-terminated polyurethane prepolymer; cool the obtained HDI-terminated polyurethane prepolymer to 30°C, add γ-aminopropyltrimethoxysilane The reaction was carried out for 4 hours to obtain a silicone-methoxy-terminated polyurethane prepolymer (i.e. polymer 1); wherein: the molar ratio of PDA: HDI: γ-aminopropyltrimethoxysilane was 1: 3: 4;

[0050] 2) Take 2 g of the polymer 1 prepared in step 1) and use it as a spinning solution after being magnetically stirred evenly; introduce the spinning solution into an electrospinning device at room temperature for electrospinning, and collect the material with an aluminum foil collecting plate;

[0051] 3) Heat the material collected ...

Embodiment 2

[0054] 1) in N 2 Under protection, add NDI to a three-necked flask equipped with a stirrer, put the three-necked flask in an oil bath and heat to 90°C, and then add dehydrated 1,4-dioxane with a mass fraction of 30 % PCL solution, mechanically stirred and reacted for 5 hours to prepare an NDI-terminated polyurethane prepolymer; cool the obtained NDI-terminated polyurethane prepolymer to 50°C, and add γ-aminopropyltrimethoxysilane to react After 1.5 hours, the polyurethane prepolymer (i.e. polymer 1) terminated by silicon methoxy was obtained; wherein: the molar ratio of PCL: NDI: γ-aminopropyltrimethoxysilane was 1: 2.5: 1.5;

[0055] 2) Take 2 g of the polymer 1 prepared in step 1) and use it as a spinning solution after being magnetically stirred evenly; introduce the spinning solution into an electrospinning device at room temperature for electrospinning, and collect the material with an aluminum foil collecting plate;

[0056] 3) Soak the material collected on the aluminu...

Embodiment 3

[0059] 1) Under the protection of N2, add TDI to a three-necked flask equipped with a stirrer, put the three-necked flask into an oil bath and heat it to 60°C, and then add the dehydrated N-methylpyrrolidone with a mass fraction of 5% PEA solution, mechanically stirred and reacted for 4 hours to prepare a TDI-terminated polyurethane prepolymer; cool the obtained TDI-terminated polyurethane prepolymer to 30°C, add γ-glycidyl etheroxypropyl trimethoxy base silane was reacted for 0.5 hours to obtain a silicon ethoxy-terminated polyurethane prepolymer (i.e. polymer 1); wherein: the molar ratio of PEA: TDI: γ-glycidyl etheroxypropyltrimethoxysilane was 1: 1.1 : 0.1;

[0060] 2) 6g (60wt%) of polymer 1, 3.9g (39wt%) of polymer 2 solution and 0.1g (1wt%) of oxide precursor solution were magnetically stirred and mixed at room temperature to prepare a spinning solution;

[0061] The polymer 2 solution is 30wt% polystyrene N,N-dimethylformamide solution;

[0062] The oxide precursor s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com