Lithium-ion secondary battery, separator and preparation method thereof

A secondary battery and lithium ion technology, applied in secondary batteries, battery components, circuits, etc., can solve the problems of low porosity, achieve strong mechanical strength, avoid short circuit, and good electrochemical stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

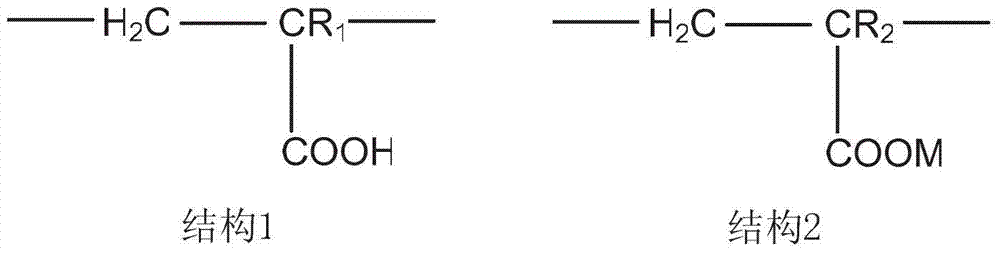

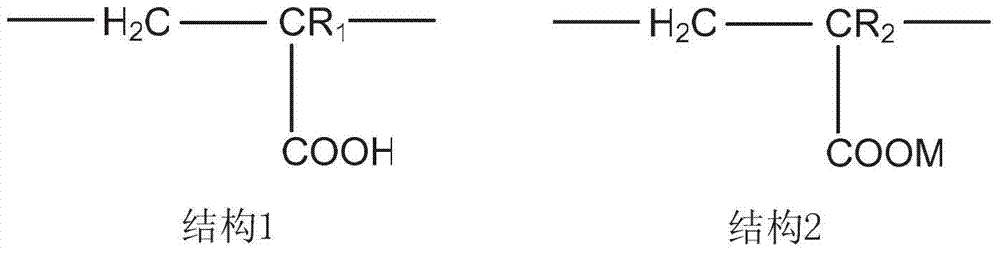

preparation example Construction

[0036] The preparation method of the separator of the lithium ion secondary battery according to the second aspect of the present invention is used to prepare the separator of the lithium ion secondary battery according to the first aspect of the present invention, comprising the steps of: (1) adding water-soluble polymer powder Added into deionized water, stirred evenly to obtain a water-soluble polymer solution; (2) adding the water-soluble solute to the obtained water-soluble polymer solution, stirred evenly at room temperature and performed ultrasonic treatment to obtain a mixed solution, wherein, the The water-soluble solute is a carbonate compound; (3) uniformly coating the obtained mixed solution on at least one surface of the porous substrate, heating and drying to obtain the separator of the lithium-ion secondary battery.

[0037] In the method for preparing a separator for a lithium-ion secondary battery according to the second aspect of the present invention, in step...

Embodiment 1

[0047] 1. Preparation of separator film for lithium-ion secondary battery

[0048] (1) Take 2kg of polyacrylic acid (PAA, water-soluble polymer) with a weight-average molecular weight of 1,000,000, add it to 8kg of deionized water in 3 times, and stir it with a rotating speed of 10r / min during the feeding process. After the feeding is completed, stir for 180 min at a speed of 800 r / min to obtain a water-soluble polymer solution with a mass fraction of 20%;

[0049] (2) Add 2kg ethylene carbonate (EC, water-soluble solute) into the resulting water-soluble polymer solution, and stir at room temperature for 1 hour at a speed of 1000r / min, so that EC is completely dissolved in the water-soluble polymer solution, and then Ultrasonic treatment was carried out for 15 minutes to remove tiny air bubbles in the solution to obtain a mixed solution, which was then sealed and shaded for later use;

[0050] (3) The obtained mixed solution is uniformly coated on one of the surfaces of the p...

Embodiment 2

[0060] Lithium-ion secondary battery is prepared according to the method of Example 1, just in the preparation of the separator of lithium-ion secondary battery (i.e. in step 1):

[0061] (2) The mass of ethylene carbonate is 3kg.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com