A film-forming method for a polymer-based solid electrolyte

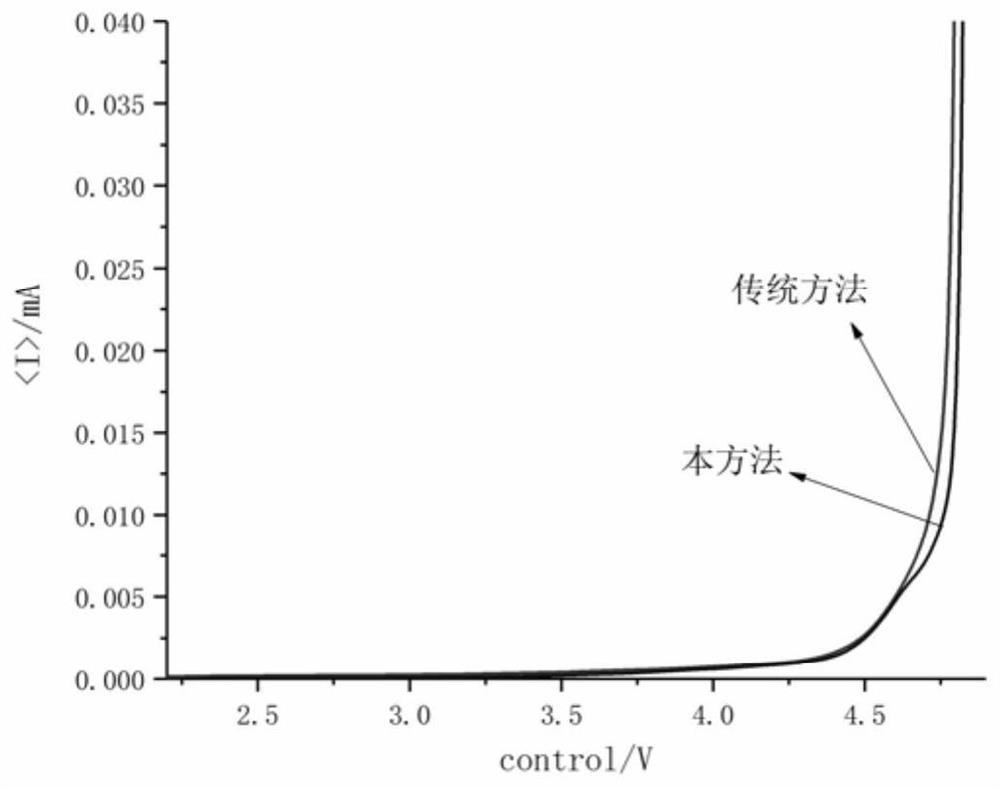

A technology of solid electrolyte and film-forming method, applied in circuits, fuel cells, electrical components, etc., can solve the problems of exposed polymer film skeleton, uneven distribution of fillers, poor structural uniformity, etc., to achieve good compositional uniformity and easy continuous. The effect of high production and production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] A film-forming method of a polymer-based solid electrolyte of the present invention, comprising the following steps:

[0032] (1) 0.5g lithium perchlorate was added in 10gDMF, stirred for 2 hours to fully dissolve the lithium salt;

[0033] (2) 3g of polymethylethylene carbonate was added to the mixed solution after step (1), stirred for 6 hours, and the viscosity was adjusted to 10Pa·s by adding DMF to obtain a homogeneously mixed polymer slurry;

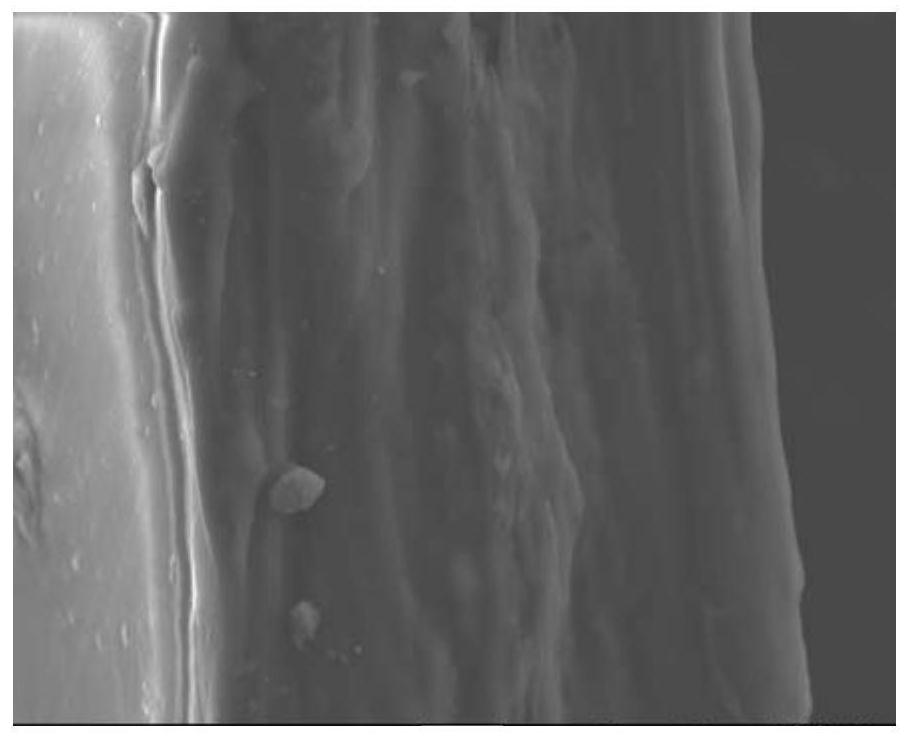

[0034] (3) The slurry is scraped and coated with a layer of 50um wet film on the glass substrate, and then covered with cellulose non-woven fabric on the surface of the wet film;

[0035] (4) Apply the polymer slurry obtained in step (2) uniformly on the surface of the cellulose non-woven fabric with a thickness of 30 μm and a pore size distribution of 0.5um to 1um by scraping, with a thickness of 200um, and then place it in 60 ℃ oven for 12 hours, and then transferred to 100 ℃ vacuum oven for 12 hours to obtain a polymer-b...

Embodiment 2

[0039] A film-forming method of a polymer-based solid electrolyte of the present invention, comprising the following steps:

[0040] (1) Add 0.8 g of lithium bis(trifluoromethylsulfonyl)imide to 10 g of acetonitrile, stir for 2 hours to fully dissolve the lithium salt;

[0041] (2) Add 5 g of polyethylene oxide to the mixed solution after step (1), stir vigorously for 24 hours, add a small amount of acetonitrile to adjust the viscosity to 30 Pa·s, and obtain a homogeneously mixed polymer slurry;

[0042] (3) Spray the slurry on a stainless steel substrate with a layer of 120um wet film, and then cover the surface of the wet film with PET non-woven fabric;

[0043] (4) Apply the polymer slurry obtained in step (2) evenly on the surface of PET non-woven fabric with a thickness of 10 μm and a pore size distribution of 25-40 μm by spraying, control the thickness at 150 μm, and then place it at 80 ° C Dry it in an oven for 12 hours to obtain a polyethylene oxide polymer membrane, ...

Embodiment 3

[0045] A film-forming method of a polymer-based solid electrolyte of the present invention, comprising the following steps:

[0046] (1) Add 0.25g lithium difluorooxalate borate to 10g tetrahydrofuran, stir for 2 hours to fully dissolve the lithium salt;

[0047] (2) 4g of polyethylene carbonate was added to the mixed solution after step (1), stirred for 6 hours, and tetrahydrofuran was added to adjust the viscosity to 20Pa·s to obtain a homogeneously mixed polymer slurry;

[0048] (3) The slurry is scraped and coated with a layer of 150um wet film on the polytetrafluoroethylene substrate, and then covered with glass fiber cloth on the surface of the wet film;

[0049] (4) Apply the polymer slurry obtained in step (2) evenly on the surface of glass fiber cloth with a thickness of 250 μm and a pore size distribution of 5 um to 10 um by scraping, control the thickness at 300 um, and then place it at 60 ° C Dry in an oven for 12 hours, and then move the preliminarily dried polym...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com