Electrical vehicle battery thermal management system

A technology for battery thermal management and electric vehicles, applied in secondary batteries, battery temperature control, circuits, etc., can solve problems such as high internal temperature of batteries, thermal runaway, poor heat dissipation, etc., and achieve high safety and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

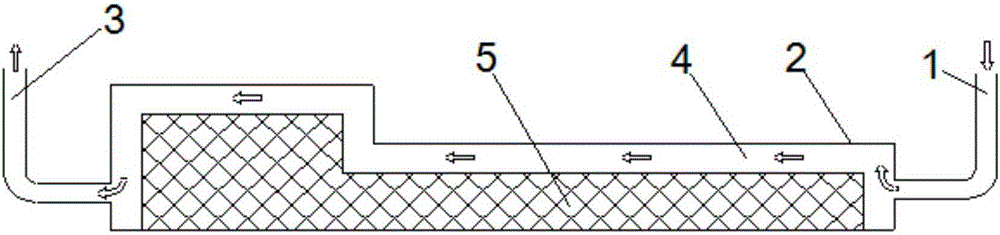

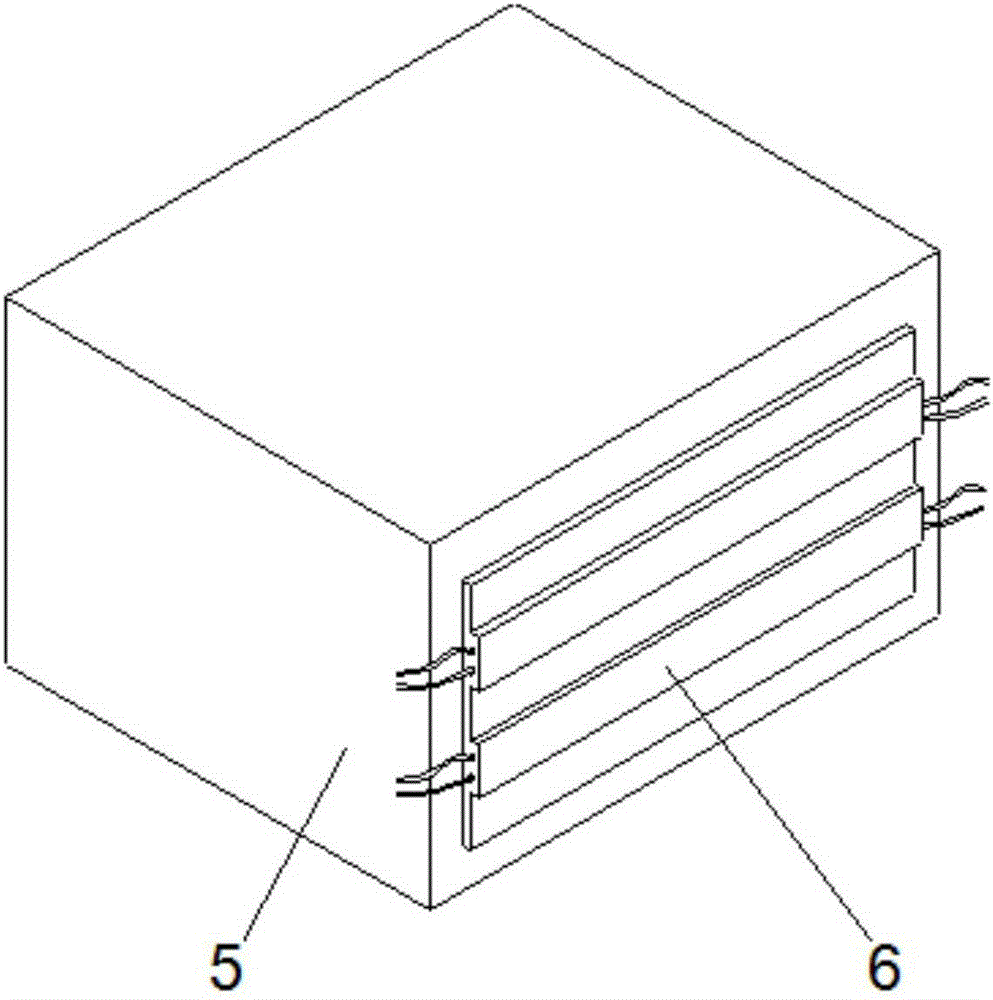

[0024] Such as Figure 5 As shown, the outer surface of the battery pack 5 is closely attached to an integrated heat exchange element 11, and the integrated heat exchange element 11 has the functions of both a heating device and a refrigeration system evaporator. The heat exchanging element 11 is embedded with PTC electric heating (heating device 13), and there are multiple microchannels 12 (for cooling) on the device.

[0025] Such as Figure 4 As shown, the microchannel 12 is connected with the vehicle-mounted air-conditioning refrigeration system to form a circulation loop, and the air-conditioning cooling system is used to cool the battery pack 5, and the cooling effect is more obvious. Such as Figure 6 As shown, the microchannel 12 is a pipeline arranged side by side, and one end of the entrance of the microchannel 12 is connected with the inlet shunt pipe, and the inlet shunt pipe is communicated with the outlet of the condenser 8 medium of the vehicle-mounted air-c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com