Efficient microstrip antenna based on non-periodic artificial magnetic conductor structure

A technology of artificial magnetic conductor and microstrip antenna is applied in the directions of antenna, radiating element structure, antenna grounding switch structure connection, etc., which can solve the problems of only radiation efficiency and poor cross-polarization suppression effect, and achieves easy processing and cost and the effect of small weight and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

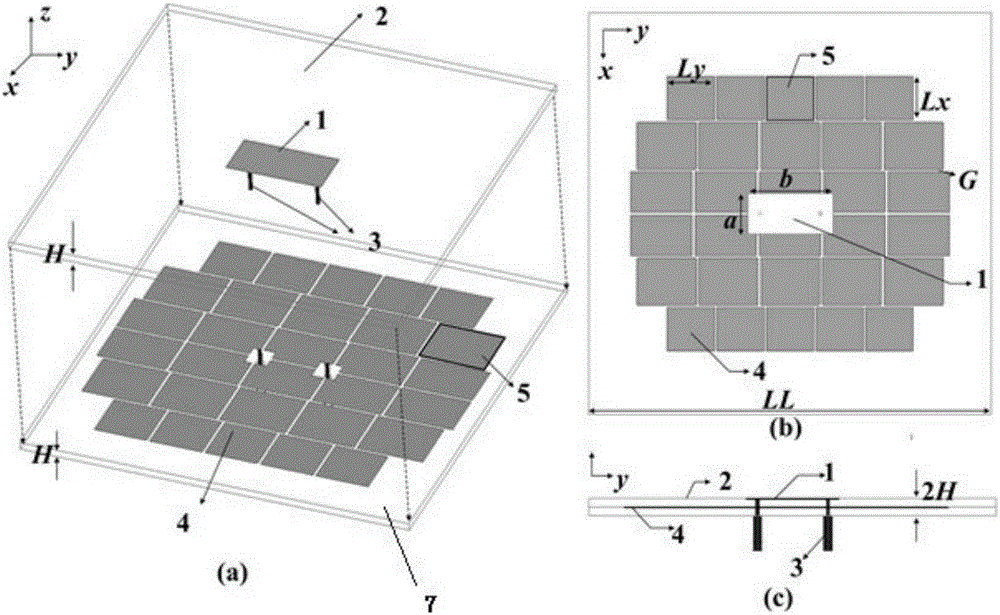

[0029] combine image 3 , the aperiodic artificial magnetic conductor reflector 4 is divided into 30 independent artificial magnetic conductor units 5, and the length Ly and width Lx of each artificial magnetic conductor unit 5 are not exactly the same, five artificial magnetic conductors in each row The length Ly and the width Lx of the units are respectively consistent, and the length and width of the artificial magnetic conductor units between different rows are not consistent. Among them, the length Ly of each row of artificial magnetic conductor units is ly1, ly2, ly3, ly4, ly5, ly6 from top to bottom, and the width Lx is lx1, lx2, lx3, lx4, lx5, lx6 from top to bottom, where ly1 =ly6, ly2=ly5, ly3=ly4, lx1=lx6, lx2=lx5, lx3=lx4.

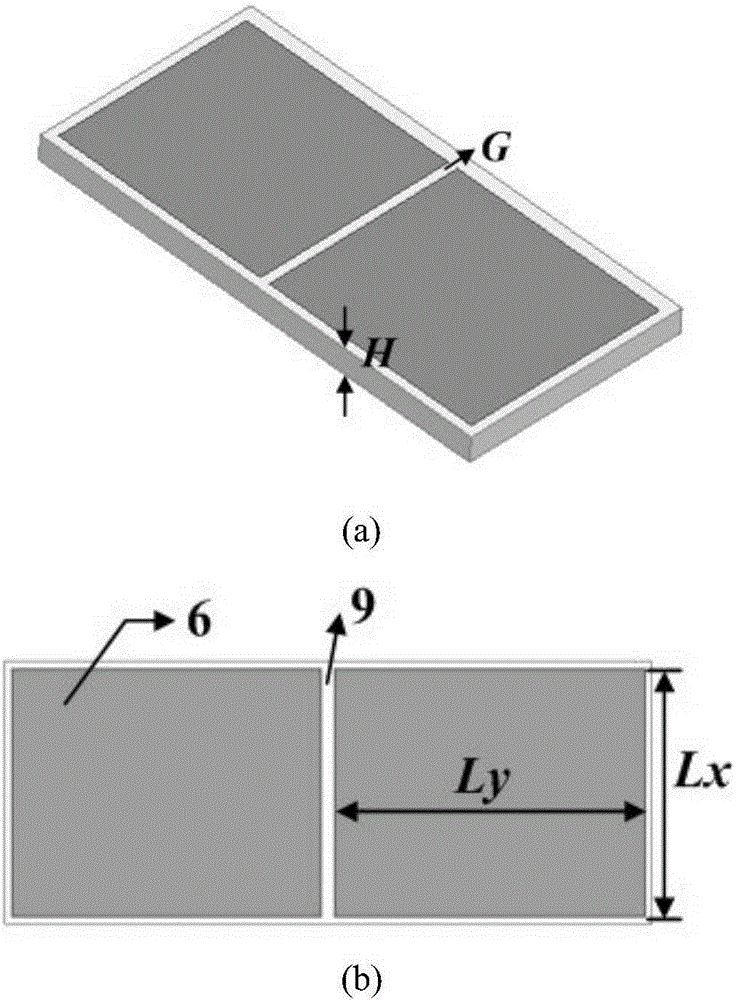

[0030] The length and width of the artificial magnetic conductor unit 5 are [0.05λ, 0.26λ], and the width of the narrow gap 9 is [0.001λ, 0.015λ]; the dielectric constant ε of the upper dielectric substrate 2 and the lower dielectric substrate...

Embodiment 2

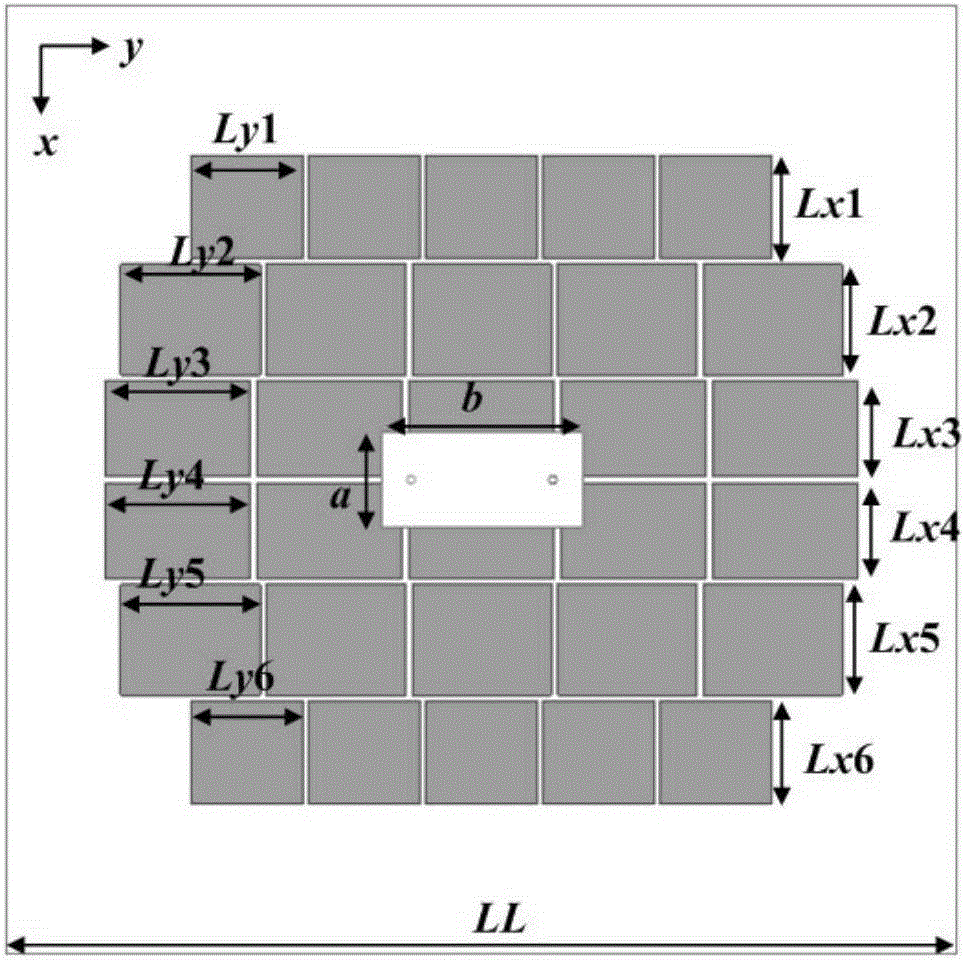

[0042] combine Figure 7 , the non-periodic artificial magnetic conductor reflector 4 is divided into 12 independent artificial magnetic conductor units 5, and the length Ly and width Lx of each artificial magnetic conductor unit 5 are not exactly the same, three artificial magnetic conductor units in each row The length Ly and width Lx of each are consistent, and the length and width of the artificial magnetic conductor units between different rows are not consistent. Wherein, the length Ly of each row of artificial magnetic conductor units is ly1, ly2, ly3, ly4 from top to bottom, and the width Lx is lx1, lx2, lx3, lx4 from top to bottom, wherein ly1=ly4, ly2=ly3, lx1 = lx4, lx2 = lx3.

[0043] The length and width of the artificial magnetic conductor unit 5 are [0.05λ, 0.26λ], and the width of the narrow gap 9 is [0.001λ, 0.015λ]; the dielectric constant ε of the upper dielectric substrate 2 and the lower dielectric substrate 7 r are [2.2,10.2], and the thickness H is [0....

PUM

| Property | Measurement | Unit |

|---|---|---|

| Reflection coefficient | aaaaa | aaaaa |

| Relative bandwidth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com