Electrified pressure leakage blocking device and method for gas leakage of sulfur hexafluoride electrical equipment

A technology of electrical equipment and sulfur hexafluoride, which is applied in the direction of switchgear, electrical components, etc., can solve the problems of inconvenient plugging of sulfur hexafluoride electrical equipment, save time for power outage maintenance, facilitate maintenance and operation, and improve power supply reliability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

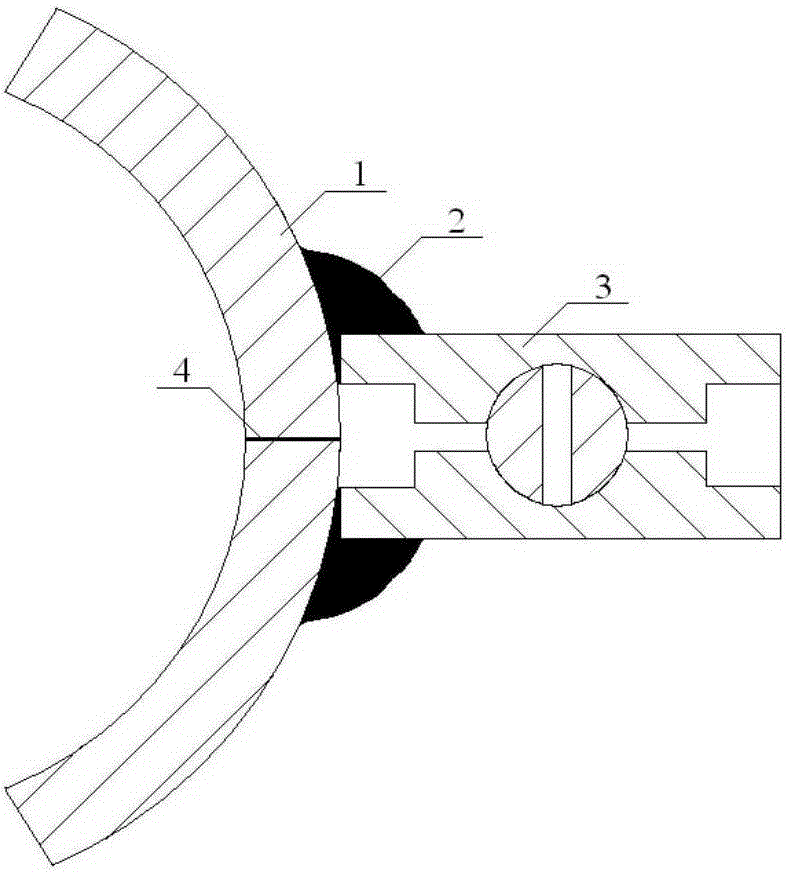

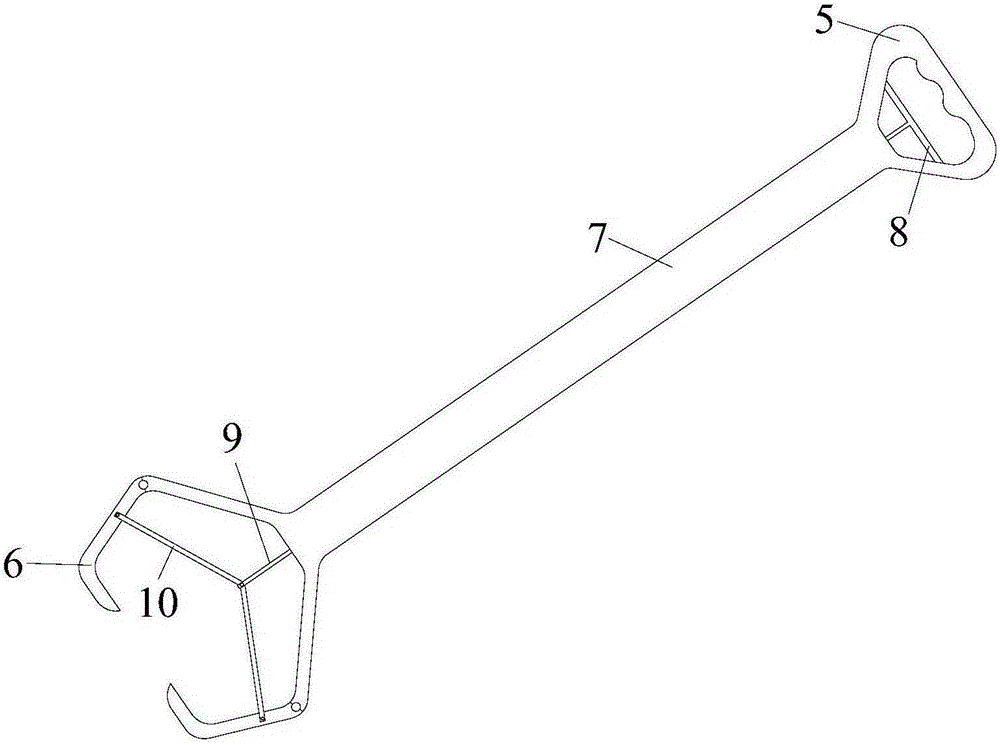

[0037] Sulfur hexafluoride gas leaked from the middle flange of phase B of a 220kV610 circuit breaker. First, use a 3.5m-long insulating fixing rod to place a ball valve with a pressure resistance of 1.6Mpa and an inner diameter of 19mm above the leak point, and sulfur hexafluoride gas will flow out of the opened ball valve.

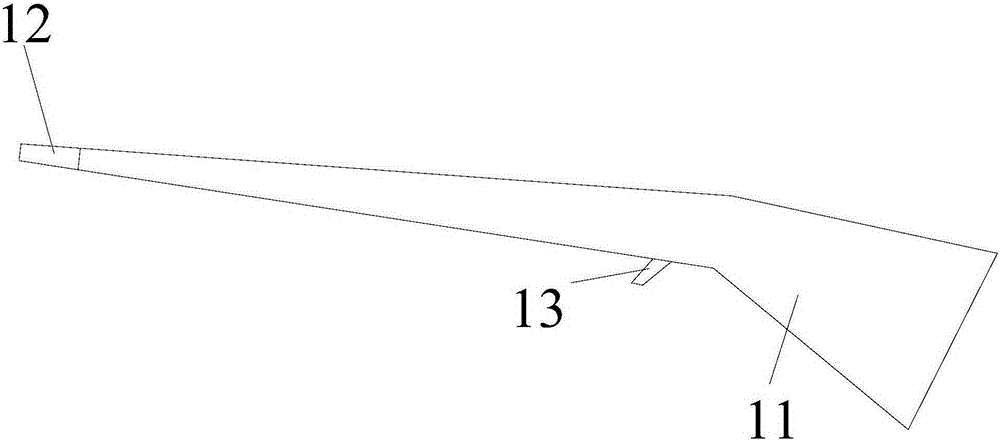

[0038] Then use a 3m long insulated glue gun to apply modified epoxy resin to the base of the ball valve.

[0039] After the modified epoxy resin is completely cured, close the ball valve, remove the insulating fixing rod, and complete the plugging.

Embodiment 2

[0041] Sulfur hexafluoride gas leaked from phase A of a 110kV outdoor GIS512 circuit breaker. First, use a 2m-long insulating fixing rod to place a disc valve with a pressure resistance of 1.0Mpa and an inner diameter of 22mm above the leakage point, and sulfur hexafluoride gas will flow out of the opened disc valve.

[0042] Then use a 2m long insulated glue gun to apply the modified polyurethane resin to the base of the disc valve.

[0043] After the modified polyurethane resin is completely cured, close the ball valve, remove the insulating fixing rod, and complete the plugging.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com