Plant holder and transplantation device

A retainer and plant technology, which is applied in the fields of botanical equipment and methods, container cultivation, gardening, etc., can solve the problems of incomplete prevention, failure to enter the retaining hole, deterioration, etc., and achieve the effect of improving workability and easy insertion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

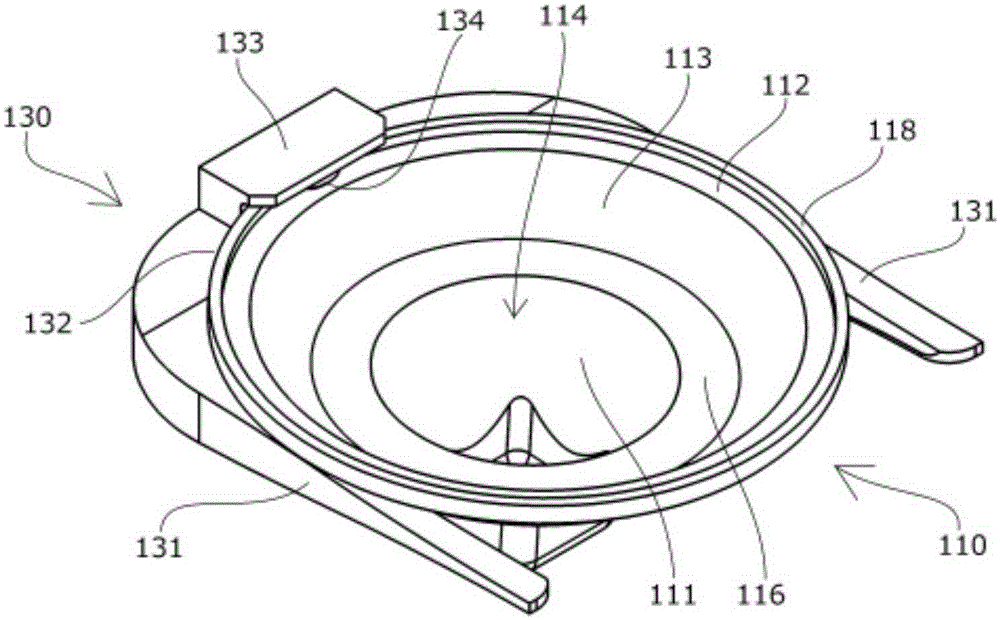

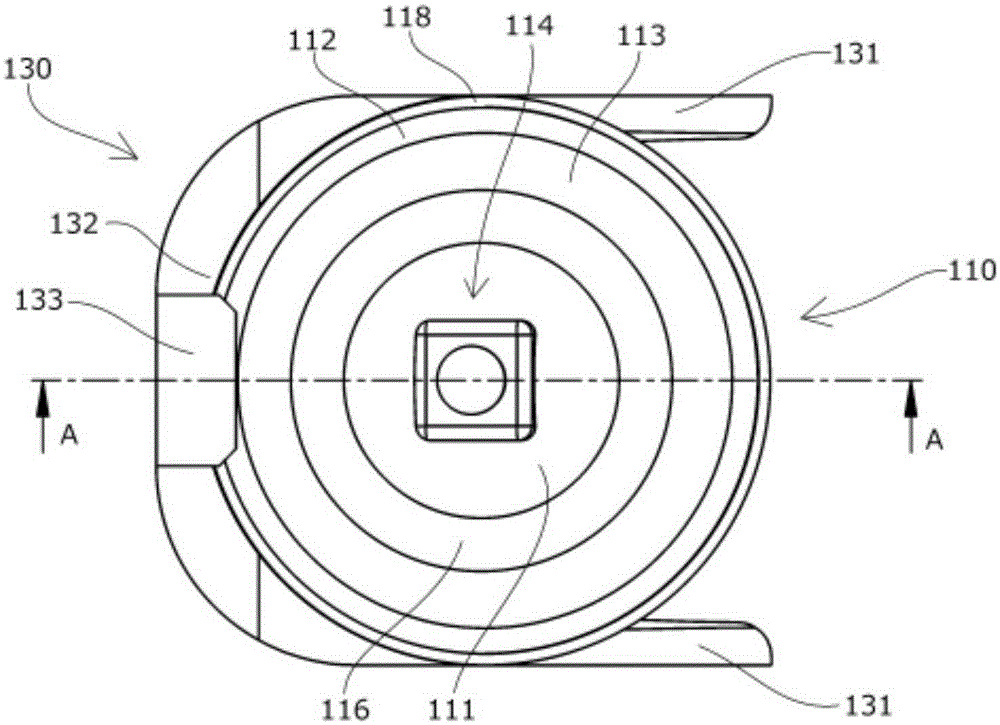

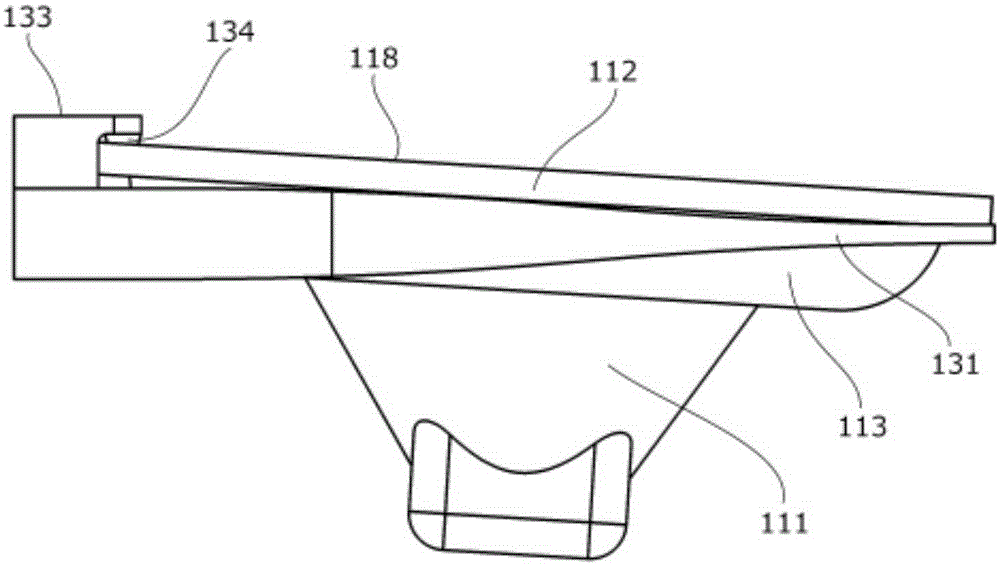

[0061] based on Figure 1 to Figure 7 One embodiment of the plant holder and transplantation device of the present invention will be described.

[0062] Plant holder 110 which is an embodiment of the present invention is integrally formed of resin or the like with a substantially uniform thickness, and has flange portion 112 , placement portion 113 , and fitting portion 111 from above.

[0063] The inner surface of the fitting portion 111 has a tapered plant support hole 114 , and the outer periphery is formed in a tapered shape that can be inserted into the holding hole 121 of the cultivation plate 120 from above.

[0064] In this embodiment, in order to maintain strength, the bottom part of the fitting part 111 is formed in a thick square shape.

[0065] The outer diameter of the placement portion 113 is larger than that of the fitting portion 111 , and has a flat portion 116 formed in a planar shape below that contacts the periphery of the holding hole 121 of the cultivati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com