Sterilization and purification reactor

A reactor and heat sink technology, applied in the field of in-line circulation devices, can solve the problems of not considering heat, reducing the effective service life of LEDs, and insufficient efficiency, so as to achieve the effect of easy maintenance, easy capacity change, and avoiding large-scale heating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

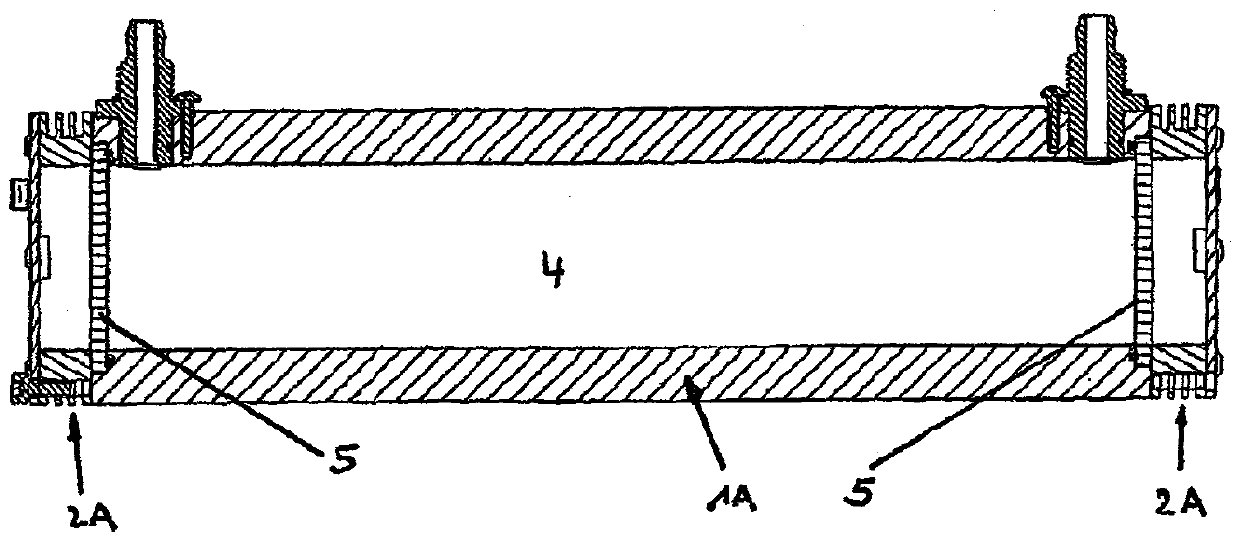

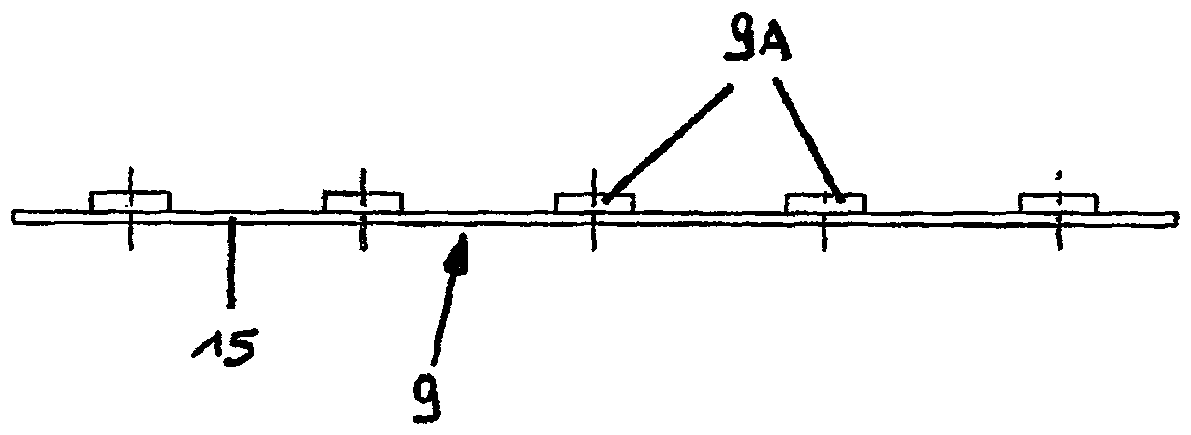

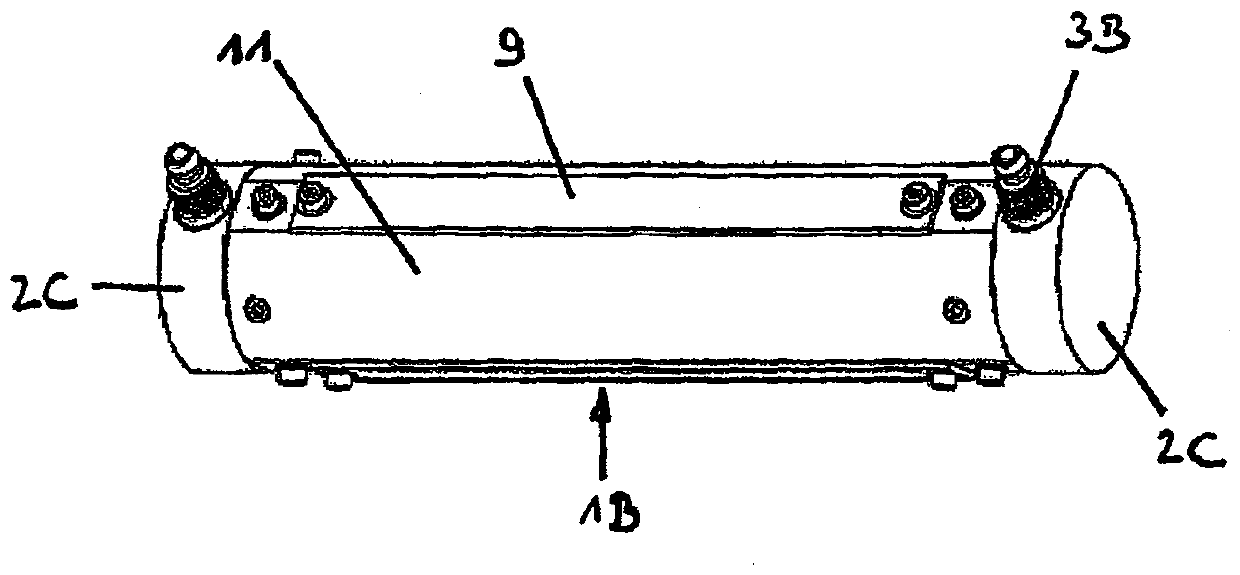

[0028] exist figure 1A first embodiment of the invention is shown in , which can be generally identified as an end cap purge reactor and more specifically a "single end cap reactor". In this type of reactor, the UV light source 7A is integrated in only one of the axial end caps 2A, 2B, which is attached to the opposite axial end of the main cylinder 1A so as to close its opposite axial end opening . The end cap 2A containing the UV light source 7A is isolated from the inner volume 4 of the master cylinder 1A by a UV transparent material in the form of a window 5, preferably made of quartz or silica glass. The end cap 2A further comprises a heat sink in the form of an annular segment 6 with surface area increasing features on its outer circumference, like fins 6a, promoting conduction and natural convection with ambient air. At the ring segment 6 a PCB 8 is attached, preferably one with a metal base improving heat transfer, for thermally conductive connection with the ring se...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com