Method for manufacturing of optical element, optical element thus obtained

A technology of optical components and components, applied in optical components, optical components, optics, etc., can solve the problems of lowering the refractive index of the final polymer, difficult to identify monomers, and incompatibility with high-viscosity systems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

[0080] 1. Chemicals used

[0081] Optical materials were prepared by:

[0082] - a first composition comprising 50.6 g of diisocyanatonorbornane (CAS No. 74091-64-8) as compound C1, 1.8 g of Seesorb 701 (CAS No. 2440-22-4) as thermal catalyst ) and 0.04 g of dimethyltin dichloride (CAS No. 753-73-1); - a second composition comprising 23.9 g of pentaerythritol tetrakis(3-mercaptopropionate) (CAS No. 7575-23-7) and 25.3 g of 2,3-bis((2-mercaptoethyl)thio)-1-propanethiol (CAS No. 131538-00-6); and

[0083] - 2 g of 9-anthrylmethyl N,N-diethylcarbamate methyl (CAS No. 1228312-05-7) dissolved in 2 g of ethyl acetate as photobase generator.

[0084] 2. Preparation of Optical Components

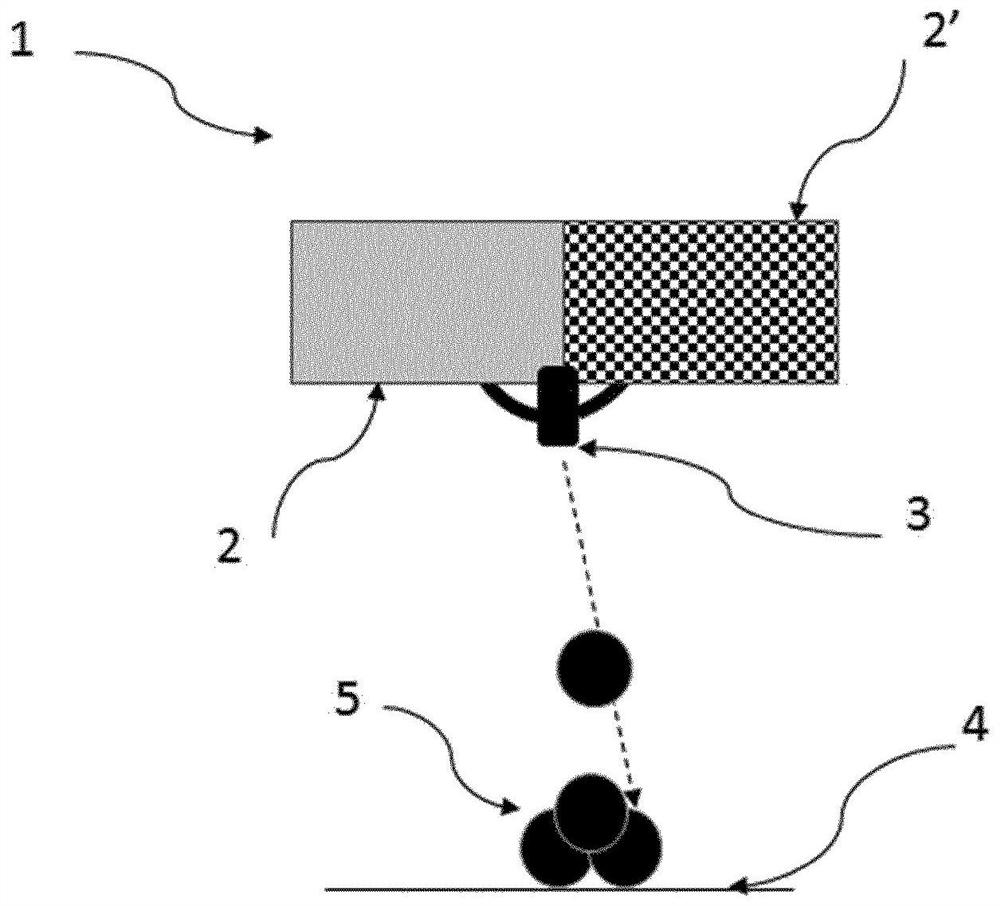

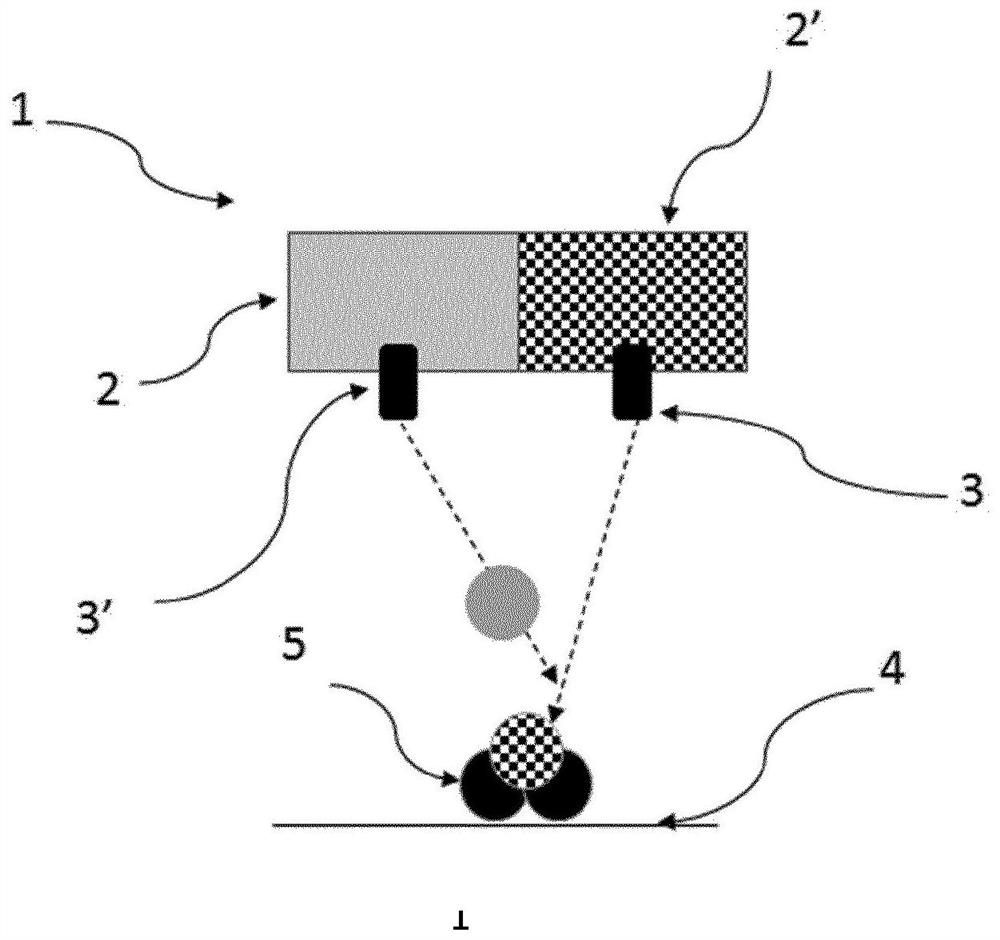

[0085] Optical elements are built on PMMA substrates by stacking multiple flat layers with different diameters, resulting in plano-convex structures.

[0086] High-end inkjet printers are used to precisely control droplet placement.

[0087] The first composition, the second composition and the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com