Control modules for electrical equipment

A technology for controlling modules and electrical equipment, which is applied in the field of heating devices and additive electric heating devices, and can solve problems such as deterioration of surrounding electronic components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

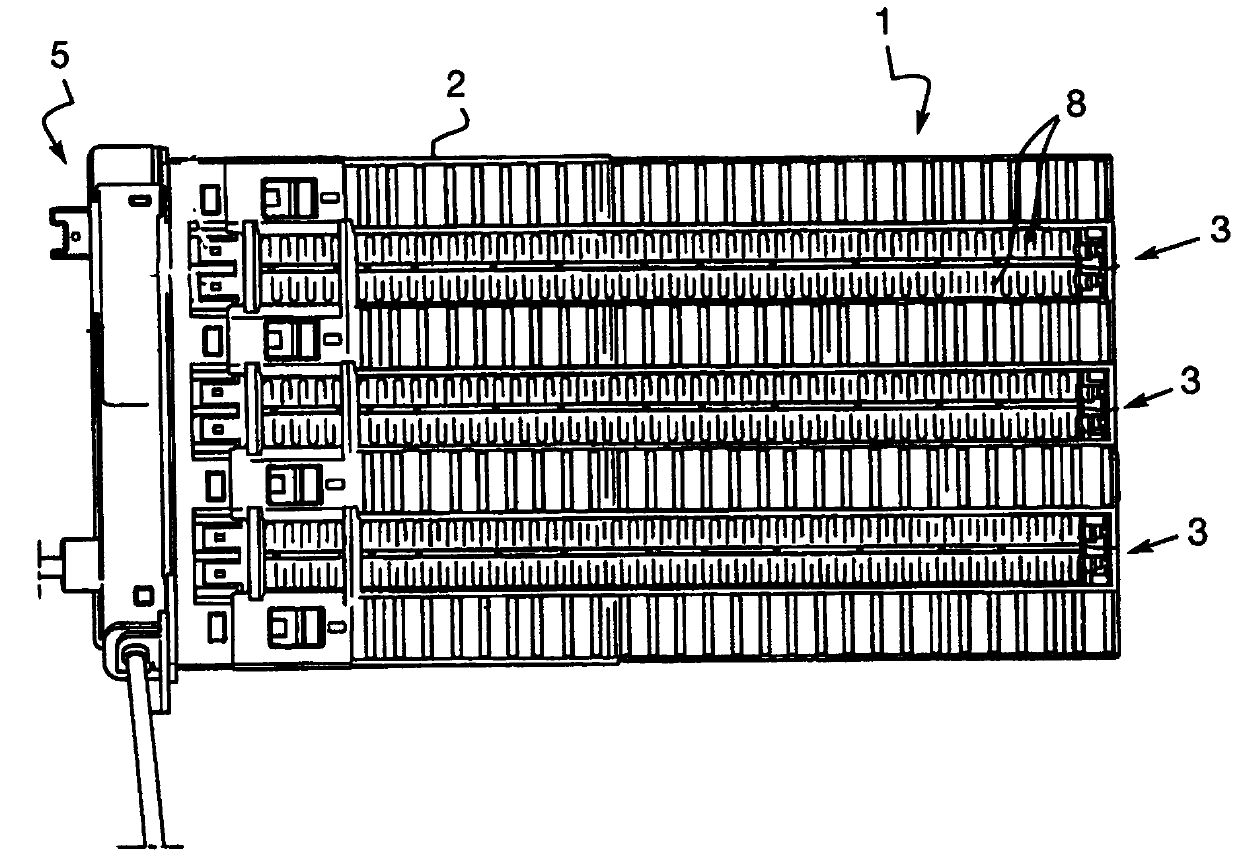

[0046] figure 1 Shown is an additive heating device 1 according to the invention, which is intended to equip a motor vehicle. Such a heating device 1 is used in particular for the first few minutes of use of the motor vehicle, when the engine is not hot enough to ensure a supply of warm air into the vehicle interior.

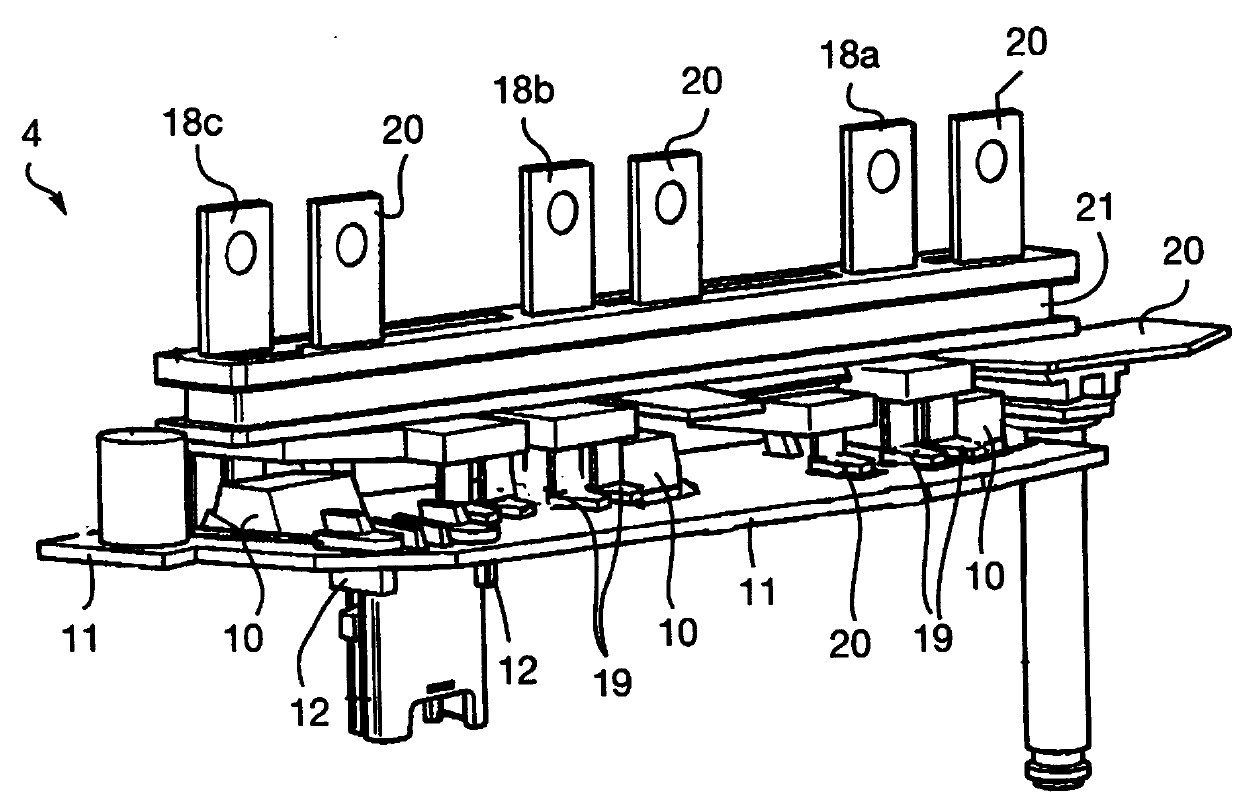

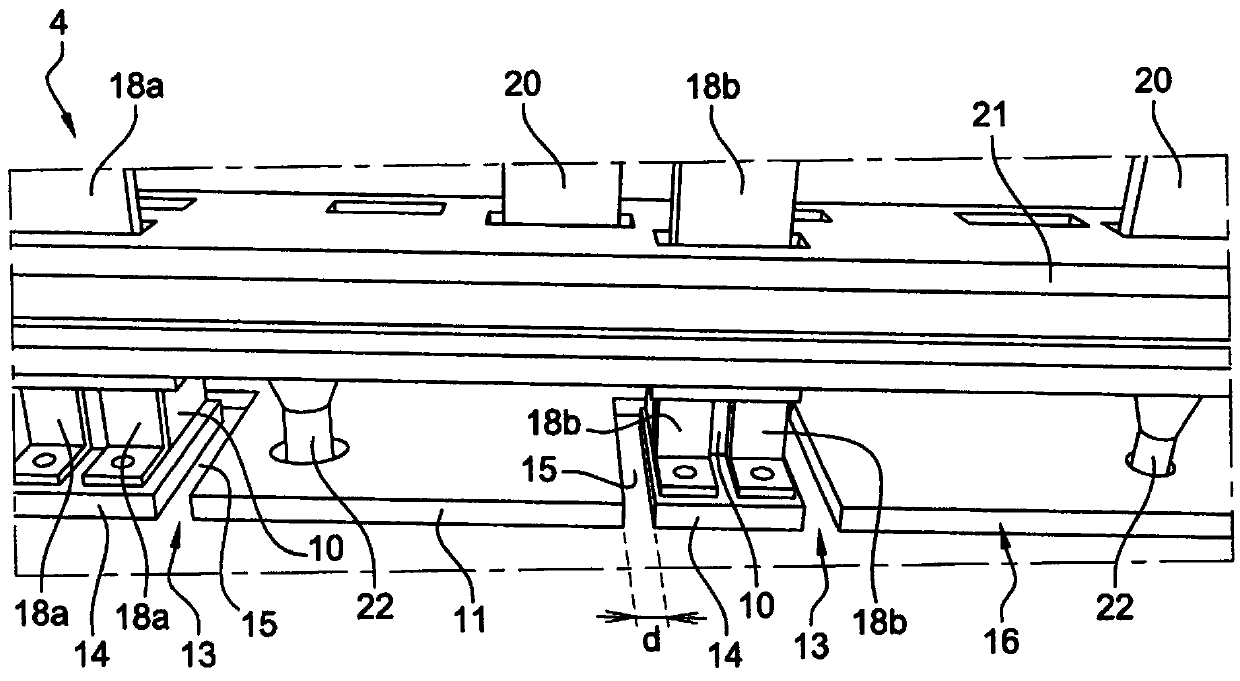

[0047] The device 1 comprises a parallelepiped support frame 2 on which are mounted parallel heating modules 3 arranged to be passed by a flow of air to be heated. Using the control module 4 ( figure 2 and 5 ) or a driver to control the heating module 3 , said control module 4 or starter is mounted in a housing 5 fixed to the support frame 2 .

[0048] Each heating module 3 includes two electrodes or terminals, in Figure 7The middle marks are + and -, and a positive temperature coefficient (PTC) type resistance element 6 is arranged between the electrodes or terminals ( Figure 7 ). Two opposing heat sinks 8 are fixed to the electrodes in order to increa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com