Double-tower bidirectional-spray multicycle desulfurization absorbing tower

A desulfurization absorption tower and multi-cycle technology, which is applied in the field of desulfurization absorption towers and wet flue gas desulfurization equipment, can solve the problems that cannot meet ultra-low emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

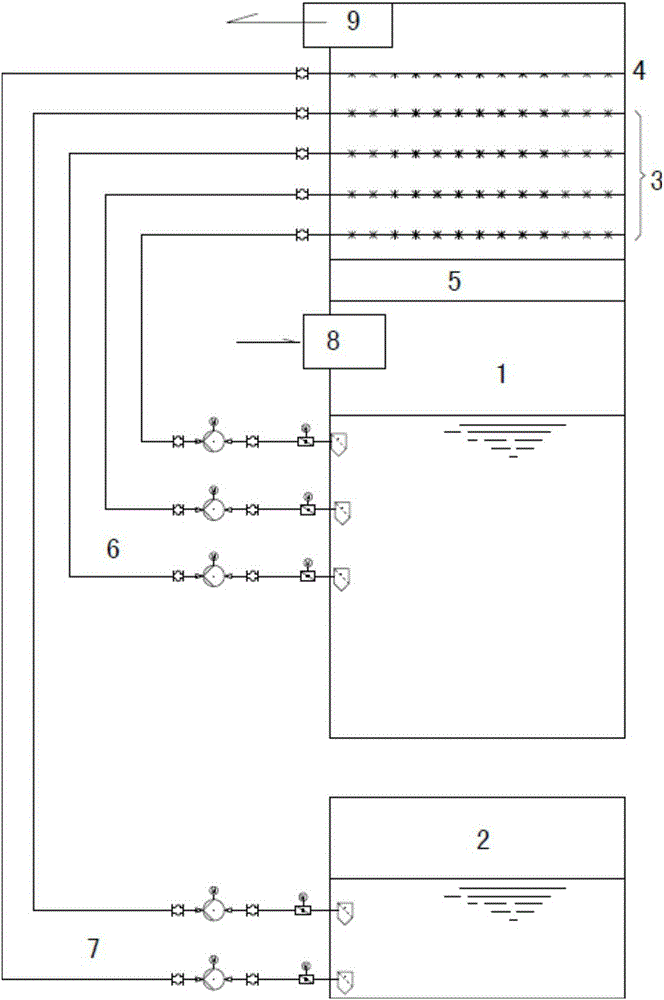

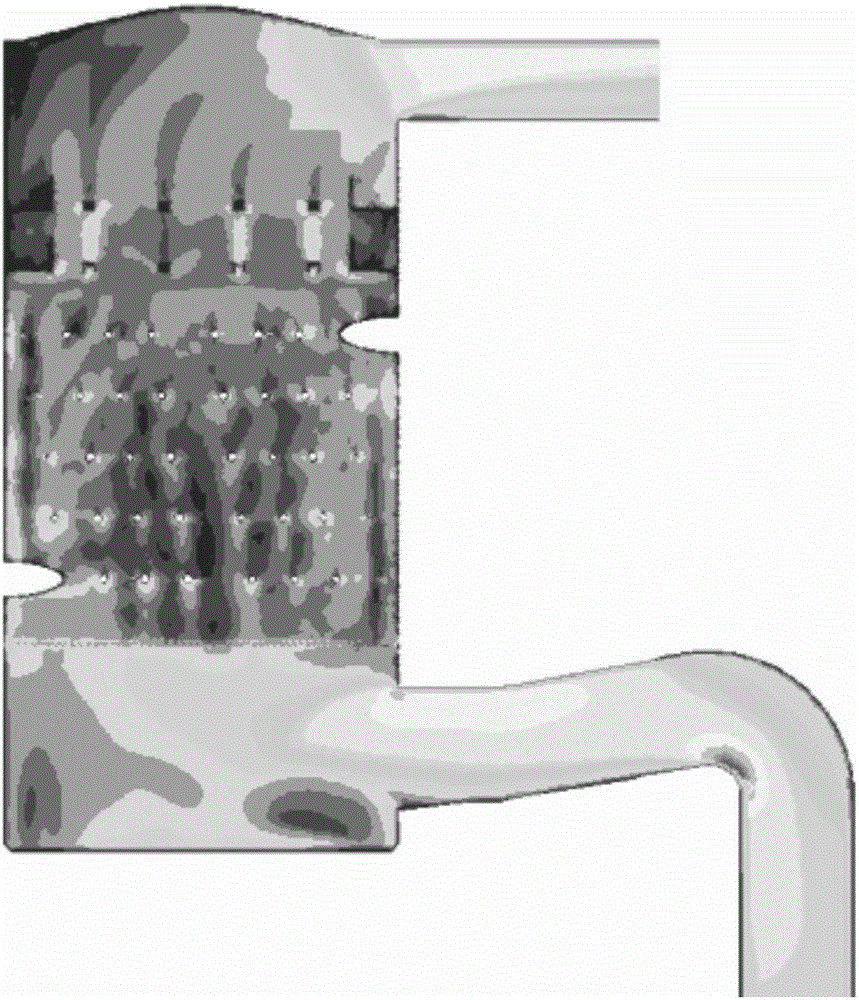

[0040] Taking an actual thermal power plant 2×300MW coal-fired generating set as an example, the application is as follows figure 1 The shown double-tower double-direction spraying and multi-circulation desulfurization absorption tower has a flue gas flow rate of 1098684m 3 / h, the inlet sulfur dioxide concentration is 3820mg / Nm 3,, the flue gas enters the tower body from the flue gas inlet, and after passing through the grid flow equalization module, the distribution of the flue gas flow field is more uniform, and then the flue gas contacts and reacts with the gypsum slurry sprayed from the spray layer. The liquid-gas ratio (volume) is 30L / m 3 , and, in the process of the flue gas passing through the spray layer, the distribution of the flow field has no dead angle, no bypass, and strong uniformity, which eliminates the unfavorable flow field caused by the uneven inlet on the inlet side of the absorption tower and the vortex of the industrial flow field influences.

[0041...

Embodiment 2

[0047] Taking another thermal power plant 2×350MW coal-fired generating set as an example, the application is as follows figure 1 The shown double-tower double-direction spraying and multi-circulation desulfurization absorption tower has a flue gas flow rate of 1390000m 3 / h, the inlet sulfur dioxide concentration is 3600mg / Nm 3 ,, the flue gas enters the tower body from the flue gas inlet, and after passing through the grid flow equalization module, the distribution of the flue gas and flue gas flow field is more uniform, and then the flue gas contacts and reacts with the gypsum slurry sprayed from the spray layer. At this time, the two The liquid-gas ratio is 30L / m 3 , and, in the process of the flue gas passing through the spray layer, the distribution of the flow field has no dead angle, no bypass, and strong uniformity, which eliminates the unfavorable flow field caused by the uneven inlet on the inlet side of the absorption tower and the vortex of the industrial flow fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com