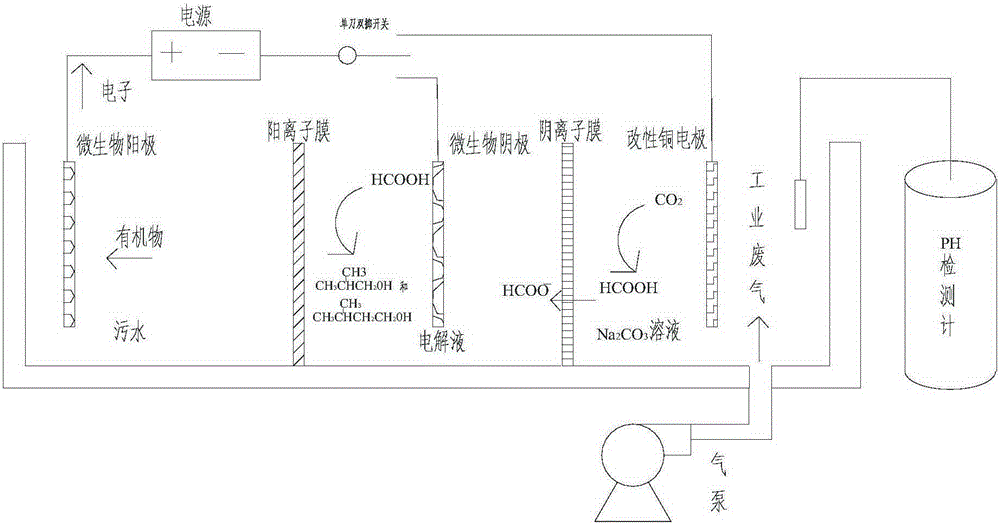

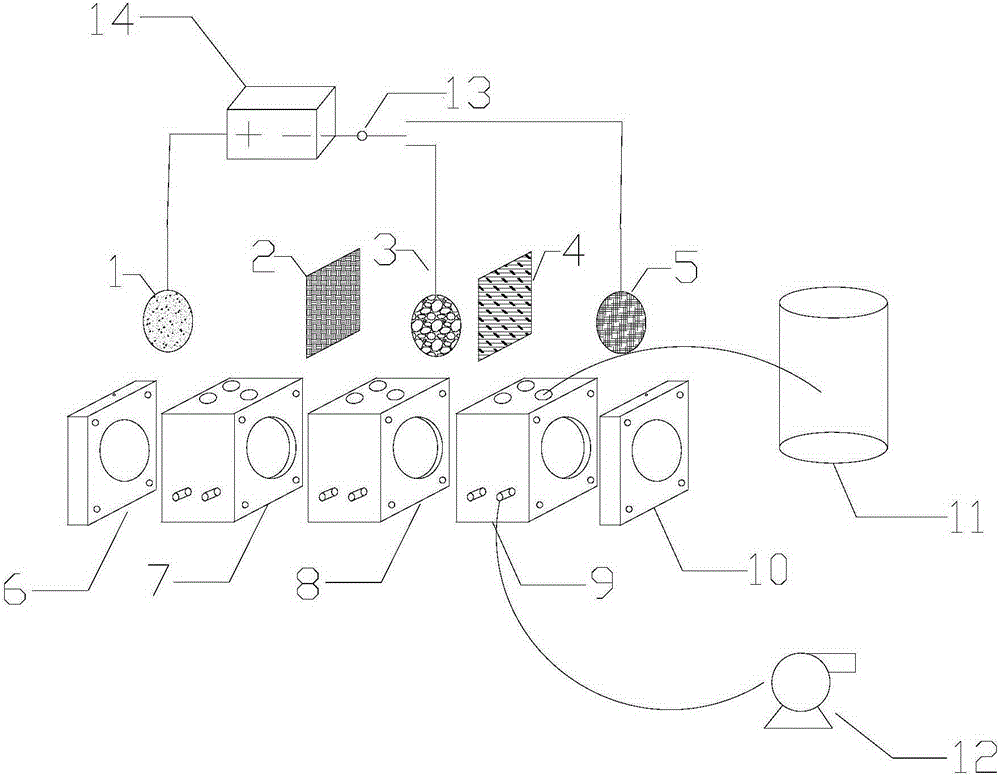

Microbial electrochemical reactor for fixing carbon dioxide in exhaust gas to generate organic products and simultaneously processing sewage and method thereof

A microbial electrochemistry, carbon dioxide technology, applied in chemical instruments and methods, biological water/sewage treatment, electrolytic organic production, etc., can solve problems such as practical limitations, and achieve the effect of reducing electric energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0059] The water entering the anode chamber is domestic sewage with a COD concentration of 1000mg / L. The carbon dioxide chamber uses Cu with a modification temperature of 300°C and a time of 10h 2 O electrode, run stably for 5 days according to the above method, regularly collect water samples and culture solution to analyze COD degradation and organic synthesis, and replace waste water with the same concentration regularly according to COD degradation, and run 5 batches in total. Results: The effluent COD decreased to 30-60 mg / l, the synthesis amount of isobutanol was 400-450 mg / l, and the synthesis amount of 3-methyl-1-butanol was 200-250 mg / l.

Embodiment 2

[0061] The water entering the anode chamber is domestic sewage with a COD concentration of 1000mg / L, and the carbon dioxide chamber uses Cu at a temperature of 300°C for 12 hours. 2 O electrode, run stably for 5 days according to the above method, regularly collect water samples and culture solution to analyze COD degradation and organic synthesis, and replace waste water with the same concentration regularly according to COD degradation, and run 5 batches in total. Results: The effluent COD decreased to 15-30 mg / l, the synthesis amount of isobutanol was 500-600 mg / l, and the synthesis amount of 3-methyl-1-butanol was 300-400 mg / l.

Embodiment 3

[0063] The water entering the anode chamber is domestic sewage with a COD concentration of 1000mg / L, and the carbon dioxide chamber uses Cu at a temperature of 300°C for 18 hours. 2 O electrode, run stably for 5 days according to the above method, regularly collect water samples and culture solution to analyze COD degradation and organic synthesis, and replace waste water with the same concentration regularly according to COD degradation, and run 5 batches in total. Results: The COD effluent of wastewater decreased to 15-30 mg / l, the synthesis amount of isobutanol was 400-500 mg / l, and the synthesis amount of 3-methyl-1-butanol was 250-300 mg / l.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com