Punching die with auxiliary punching mechanism

A technology of punching die and elastic mechanism, which is applied in the direction of manufacturing tools, perforating tools, feeding devices, etc., can solve the problems of inaccurate hole positions, affecting production work, and circular pipe deviation, so as to improve the strength and rigidity, improve the The effect of improving the service life and work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

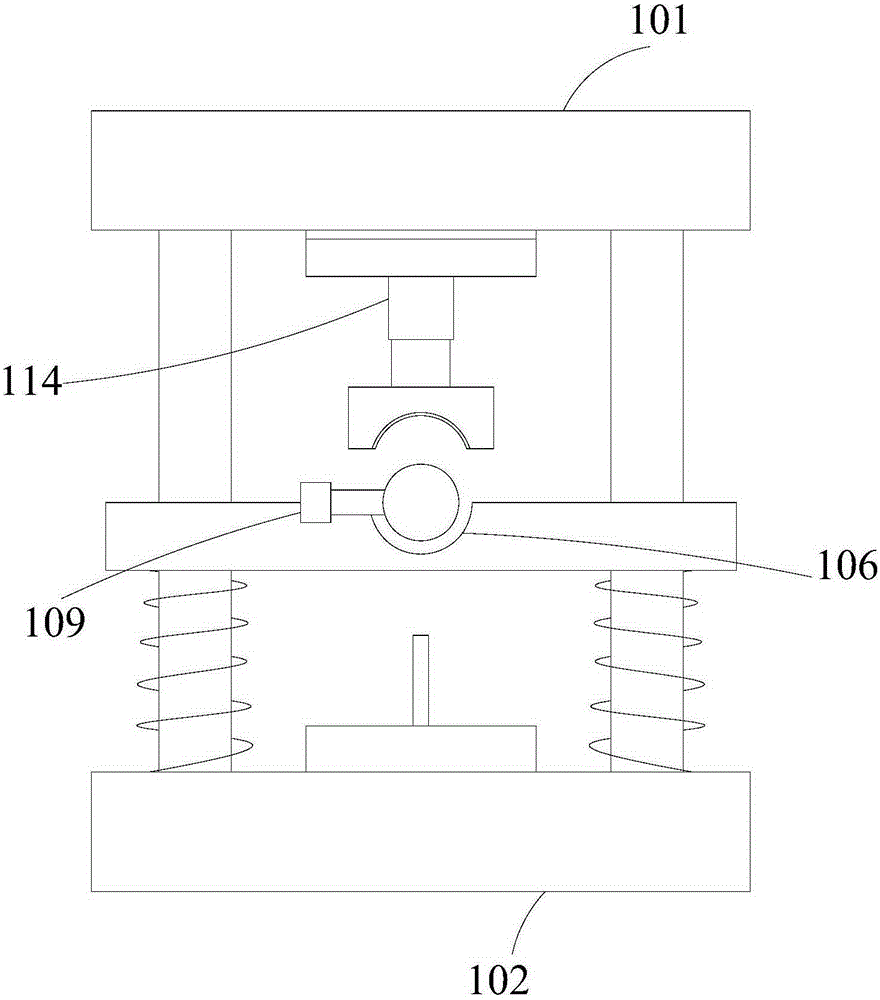

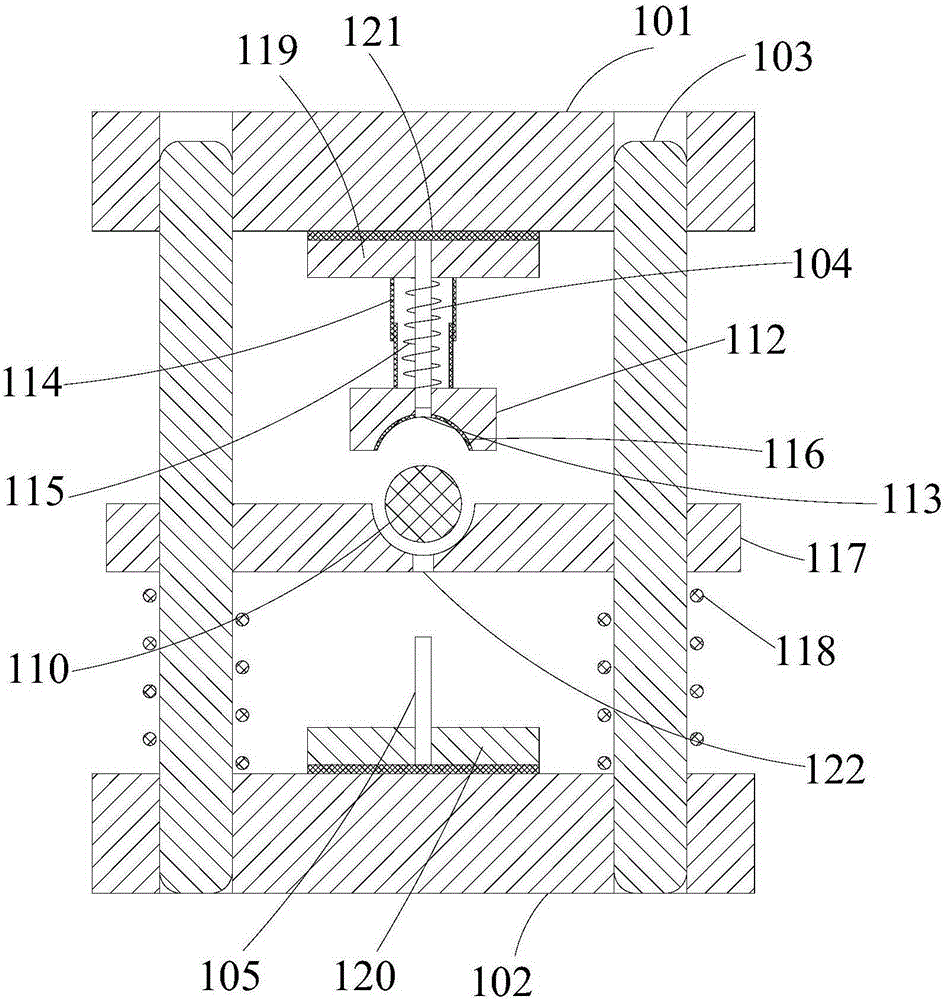

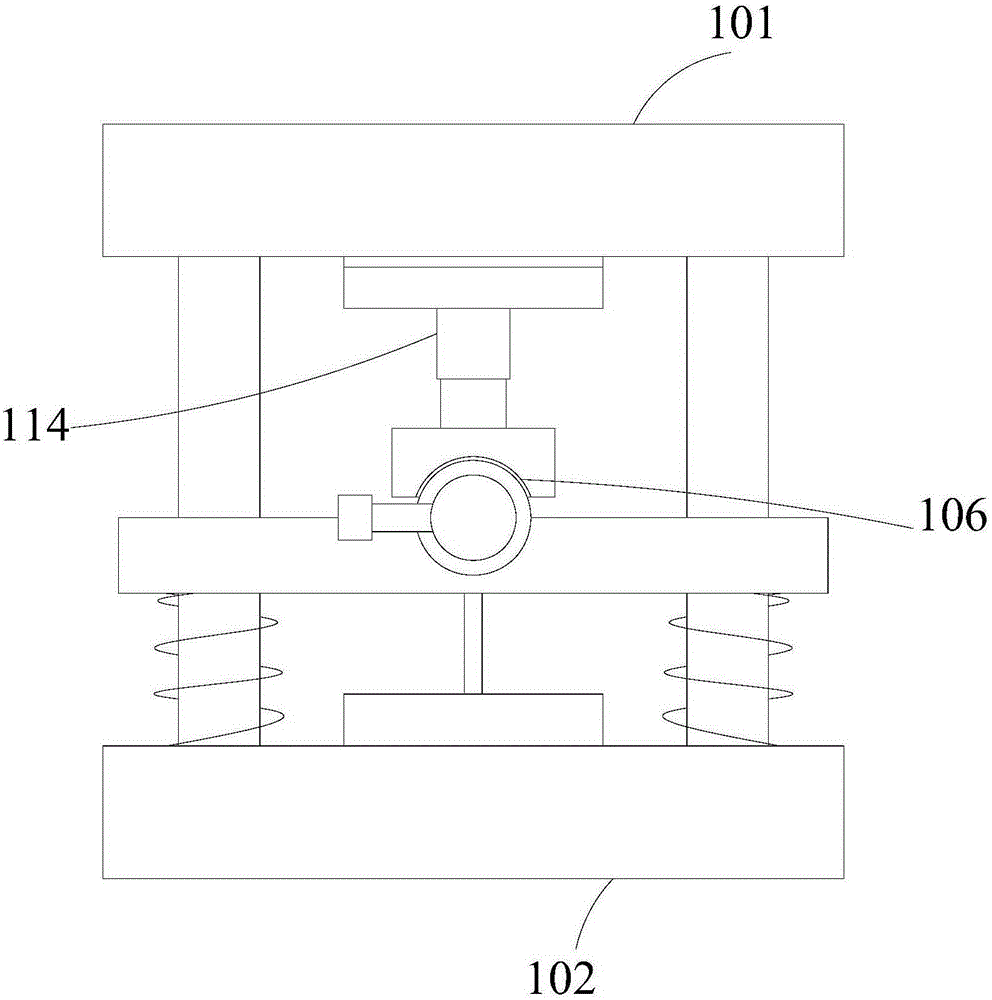

[0077] A punching die with an auxiliary punching mechanism, comprising an upper die base 101 and a lower die base 102, the upper die base 101 and the lower die base 102 are connected by a guide post 103, and an upper punch is connected to the bottom of the upper die base 101 104, the lower mold base 102 is longitudinally provided with a circular tube placement part 106; the outside of the upper punch 104 is provided with an auxiliary punching mechanism, the auxiliary punching mechanism includes a positioning block 112, the bottom surface of the positioning block 112 is a tensile structure, The outline of its bottom surface in the longitudinal section of the positioning block 112 is an arc, and the positioning block 112 is provided with a vertical through hole 113, and the upper punch 104 passes through the through hole 113; 101, the elastic mechanism enables the positioning block 112 to move in the vertical direction.

[0078] The elastic mechanism includes a sleeve assembly 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com