Method for repairing breaking cage-shaped rotor cage bars

A repair method and rotor cage technology, which is applied in the manufacture of squirrel cage rotors, stator/rotor bodies, etc., can solve problems such as economic losses, scratches on stator windings, and inability to ensure long-term operation of motors, so as to delay failures and avoid secondary problems. The effect of secondary damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] An embodiment of the present invention provides a cage-shaped rotor cage bar fracture repair method, which includes the following steps:

[0020] Clean up the welding place before welding: first remove the old welding bump and scale, then remove the grooves on both sides of the broken cage bar facade, and then remove the metal powder and other impurities in the welding place;

[0021] Welding: When the temperature of the weld seam is heated to 380°C, apply flux to the weld seam, continue to heat until the weld seam temperature reaches 780°C, touch the silver solder to the weld seam, wet and fill the weld seam, forming Brazing seam, so that the brazing material and the end ring diffuse each other and are firmly combined;

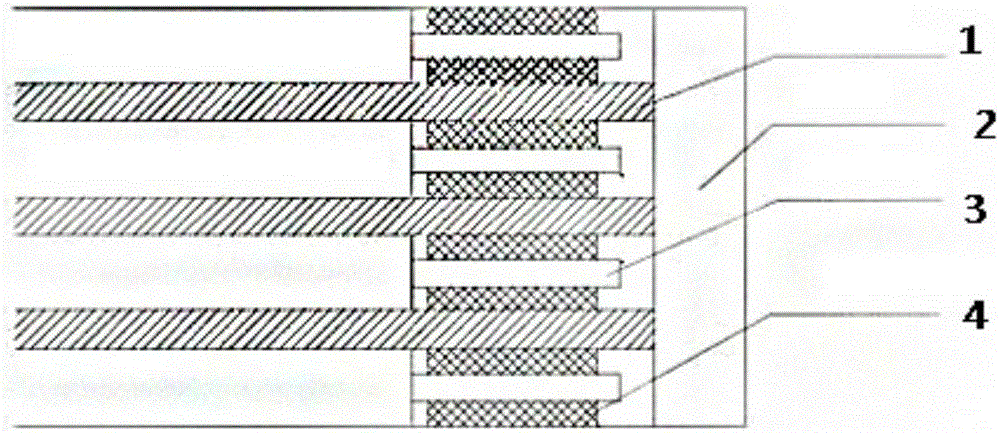

[0022] Filling expansion material: such as figure 1 As shown, according to the distance between the end cage bar and the tooth pressure plate, cut the expansion conformable material whose size matches the distance, and then brush the expansion conform...

Embodiment 2

[0028] An embodiment of the present invention provides a cage-shaped rotor cage bar fracture repair method, which includes the following steps:

[0029] Clean up the welding place before welding: first remove the old welding bump and scale, then remove the grooves on both sides of the broken cage bar facade, and then remove the metal powder and other impurities in the welding place;

[0030] Welding: When the temperature of the weld seam is heated to 400°C, apply flux to the weld seam, continue to heat until the weld seam temperature reaches 800°C, touch the silver solder to the weld seam, wet and fill the weld seam, forming Brazing seam, so that the brazing material and the end ring diffuse each other and are firmly combined;

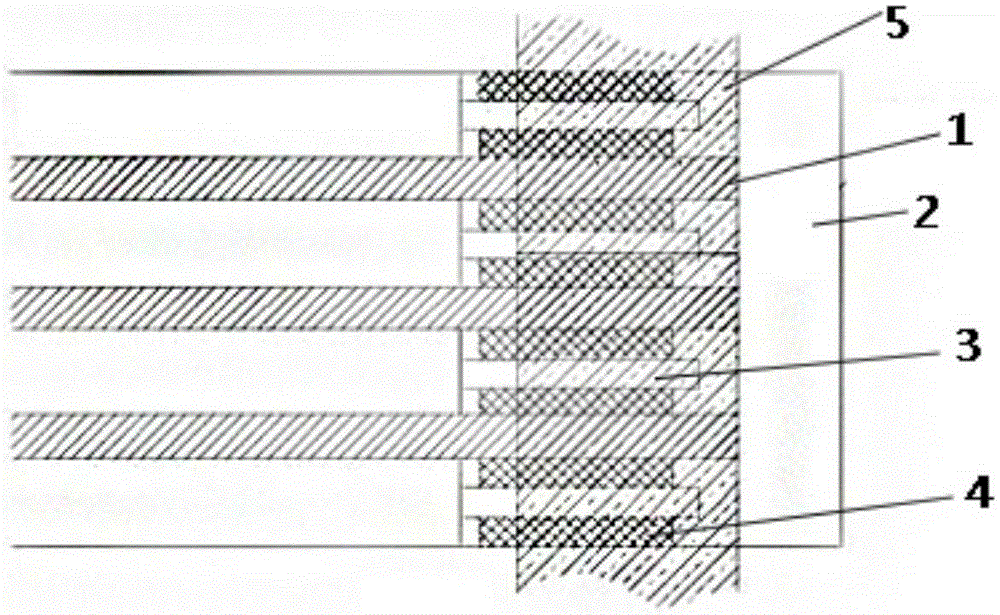

[0031] Filling with expansion material: According to the distance between the end cage bar and the tooth pressure plate, cut the expansion conformable material whose size matches the distance, and then brush the expansion conformable material with insu...

Embodiment 3

[0037] A cage-shaped rotor cage bar fracture repair method, it comprises the following steps:

[0038] Clean up the welding place before welding: first remove the old welding bump and scale, then remove the grooves on both sides of the broken cage bar facade, and then remove the metal powder and other impurities in the welding place;

[0039] Welding: When the temperature of the weld seam is heated to 420°C, apply flux to the weld seam, and continue heating until the weld seam temperature reaches 820°C, then touch the silver solder to the weld seam, wet and fill the weld seam, forming Brazing seam, so that the brazing material and the end ring diffuse each other and are firmly combined;

[0040] Filling with expansion material: According to the distance between the end cage bar and the tooth pressure plate, cut the expansion conformable material whose size matches the distance, and then brush the expansion conformable material with insulating paint;

[0041] Binding non-weft ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com