Air hose dehydration cabinet

A technology of water tanks and air ducts, which is applied to hull ventilation/heating/cooling, ship components, ships, etc. It can solve problems such as safety and life threats of navigation equipment, influence of ship structure, and difficult layout, so as to ensure ventilation reliability, The effect of great promotion value and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

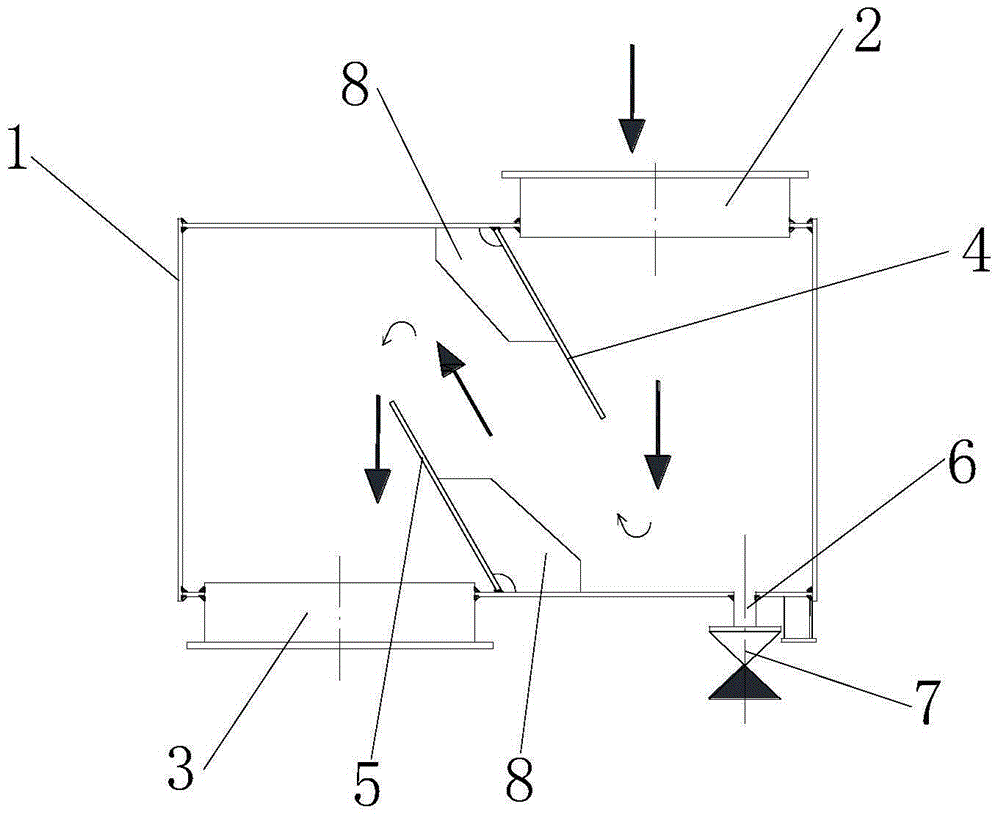

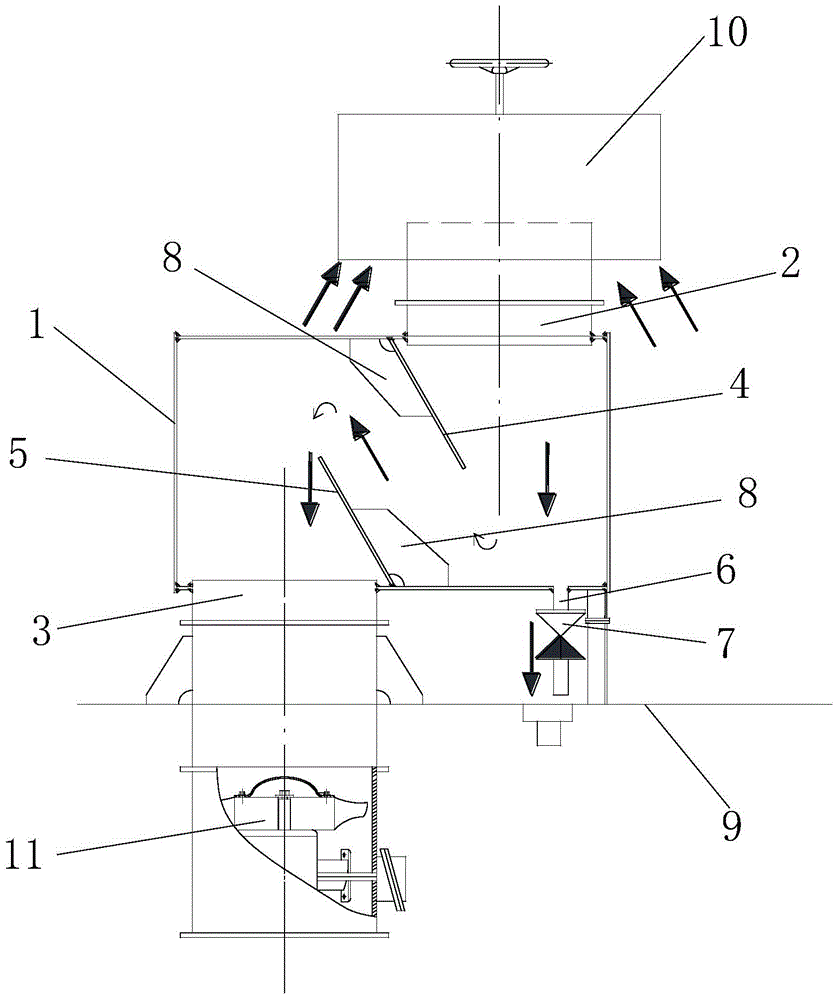

[0018] Such as figure 1 As shown, the air duct water removal cabinet of this embodiment includes a cabinet body 1, an air inlet port 2 is arranged on the top plate of the cabinet body 1, an air outlet port 3 is arranged on the bottom plate of the cabinet body 1, and the The air inlet interface 2 and the air outlet interface 3 are misplaced, and the inside of the cabinet body 1 is also provided with a wind guide and water removal device. The wind and water removal plate 5, the upper wind guide and water removal plate 4 and the lower wind and water removal plate 5 are arranged at a certain inclined angle between the wind interface and the air outlet interface 3, corresponding to the bottom plate at the air inlet interface 2 A drain port 6 is also provided, and a check valve 7 is arranged on the drain port 6. The present invention can effectively enable the air coming in from the air inlet port 2 to pass through the wind guide and dewatering device, and enter the cabin 11 through...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com