Corner lift for sliding plates

A lift, skateboard technology, applied in the direction of lifting device, etc., can solve the problem that the number of occupied stations affects the utilization rate of the workshop, etc., and achieves the effects of convenient and fast installation, low production cost, and reliable and stable operation of the mechanism.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

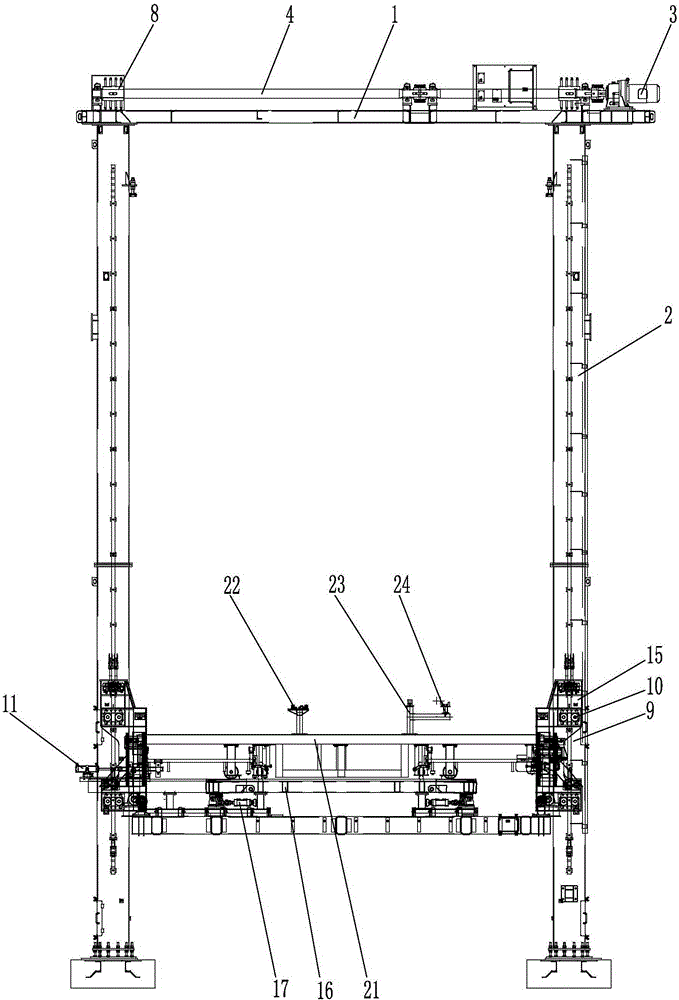

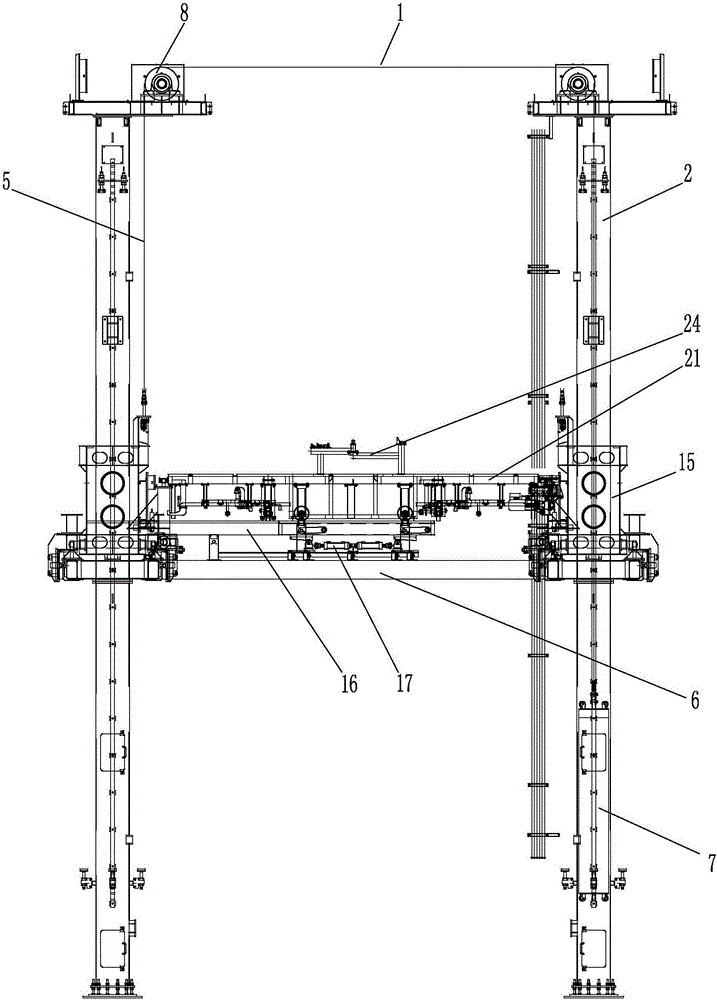

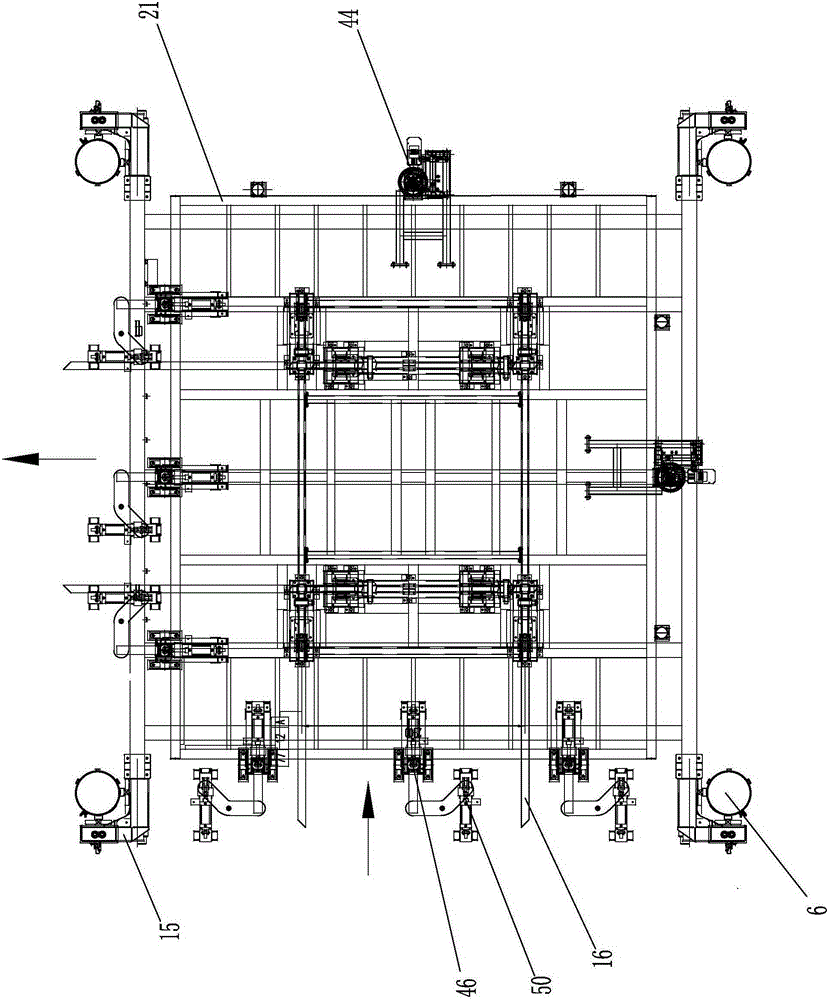

[0033] Such as Figure 1-11 As shown, the skateboard corner elevator includes a lifting system, a direction changing track system, a friction drive system, and a skateboard alignment locking device 11;

[0034] The lifting system consists of a driving platform 1, four hollow circular tube guiding columns 2, a reducer 3, a driving spindle 4, a driving chain 5, a lifting frame 6, and a counterweight device 7. A horizontal driving platform is set on the top of the guiding column 2, and the lifting The frame 6 is horizontally arranged between the four guide columns 2 through the guide wheel devices 15 provided on its four corners, and the driving platform 1 on the top of the guide column 2 is respectively provided with a drive sprocket 8 corresponding to the guide column 2, and the four drive The sprockets 8 are respectively driven by two speed reducers 3, and the two drive sprockets 8 driven by the same speed reducer 3 are connected through the drive spindle 4. The guide wheel de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com