Manufacturing method for interior wall ceramic tile with metallic luster layer

A technology of metallic luster and manufacturing method, which is applied in the field of ceramic tile manufacturing, can solve the problems of low cost and limit the design space of ceramic tiles, and achieve the effect of saving manufacturing cost and simplifying manufacturing steps.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

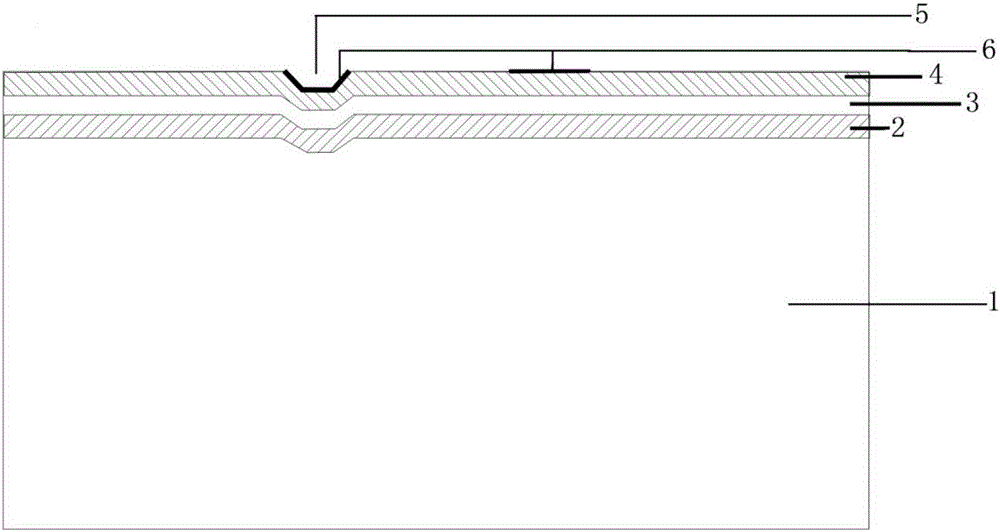

[0022] The present invention will be further described below in conjunction with the accompanying drawings. It should be noted that this embodiment is based on the technical solution, and provides detailed implementation and specific operation process, but the protection scope of the present invention is not limited to the present invention. Example.

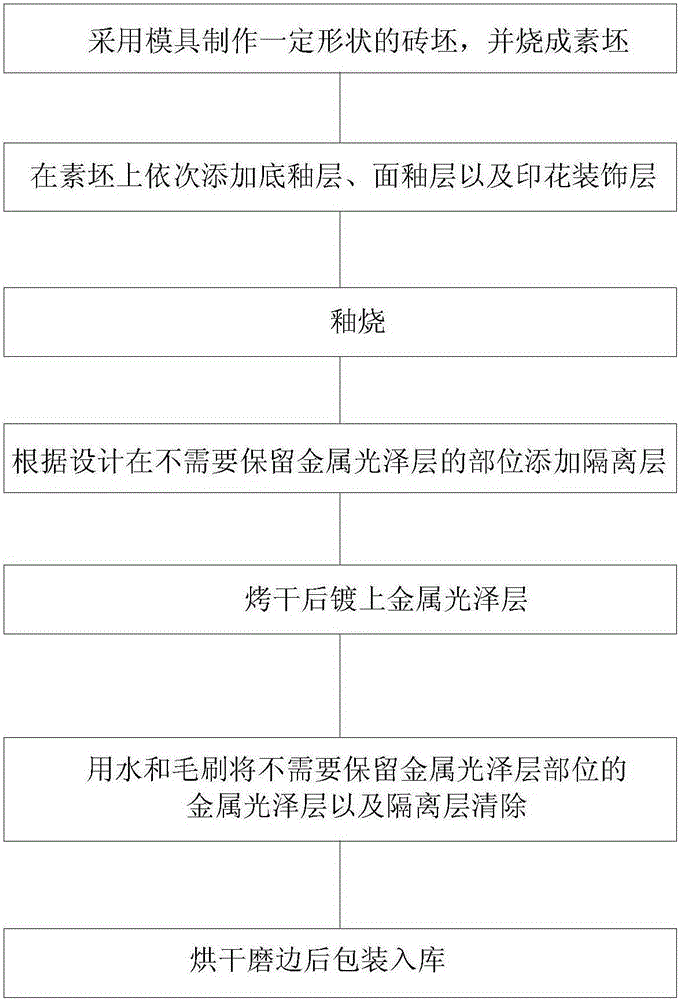

[0023] Such as figure 1 , figure 2 Shown, a kind of manufacture method of inner wall tile with metallic luster layer, comprises the steps:

[0024] S1 uses a mold to extrude the ceramic powder into a certain shape of adobe, and then fires it into a green adobe. In this embodiment, the specification of the tiles for the inner wall is 300×600mm, and the raw material of the tiles is a ceramic powder known in the prior art with kaolin, clay, sand, etc. as the main raw materials, supplemented by other auxiliary materials such as magnesia soil .

[0025] The mold can be customized by the mold manufacturer according to the design ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com