Soft seal gate valve

A soft sealing, gate valve technology, applied in sliding valves, valve devices, engine components, etc., can solve the problems of large opening torque, easy to burst, low tensile strength, etc. The effect of high tensile strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

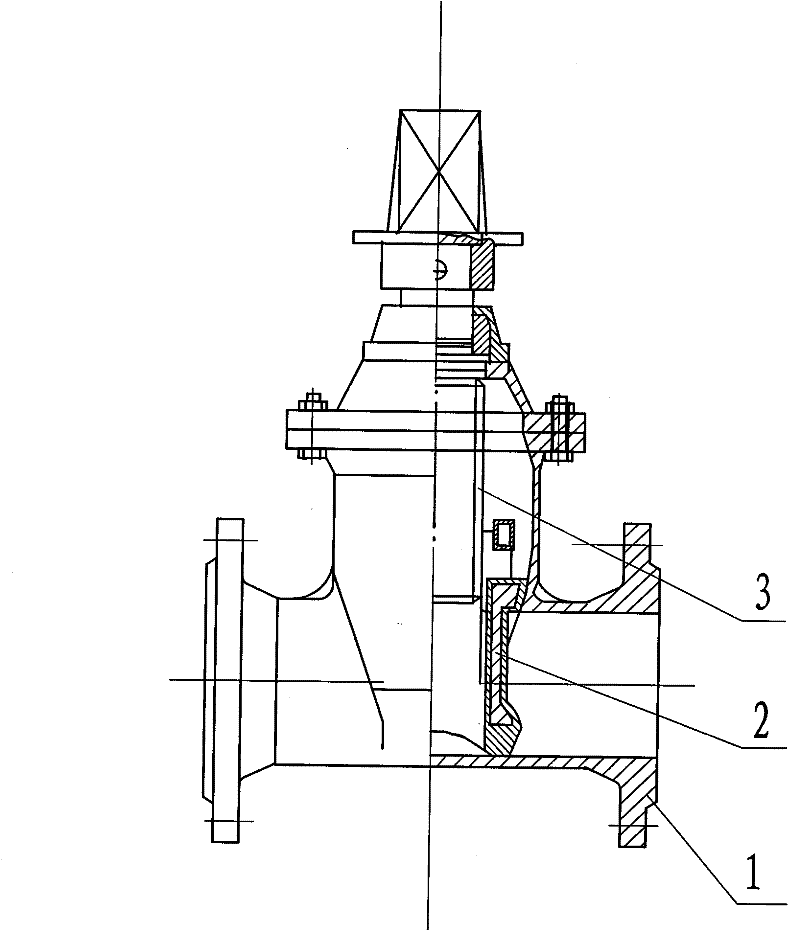

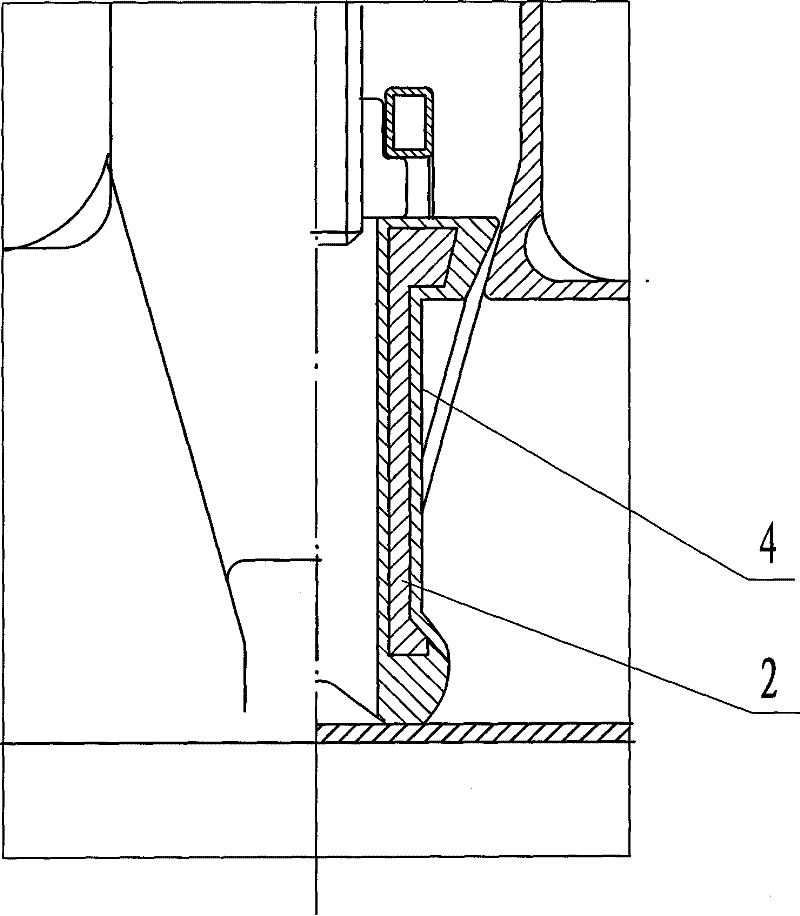

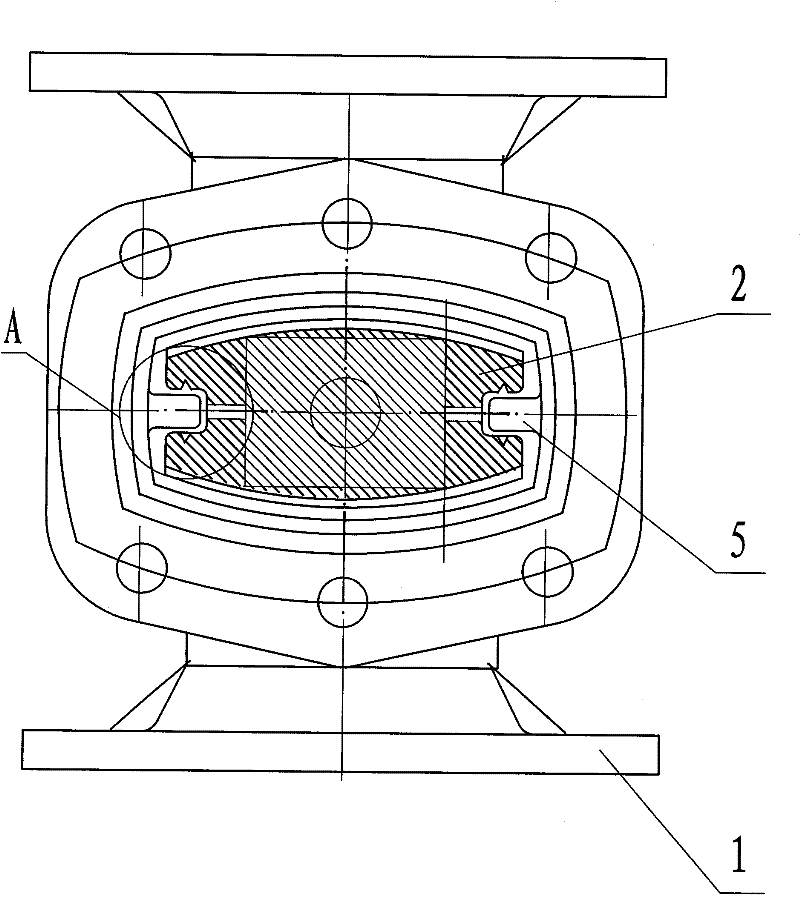

[0021] A soft-sealed gate valve includes a valve body 1, a gate plate 2 that moves up and down along gate slideways 5 on both sides of the valve body, and a valve stem 3 that operates the gate plate to move up and down to open and close. The ram chute 6 on both sides of the ram 2 sliding on the ram chute 5 is provided with a pressure protection groove 7 for reducing the liquid pressure at the contact part between the ram chute 6 and the ram chute 5 . The valve body 1, the gate plate 2 and the castings of the valve are all made of high tensile strength ductile iron QT450-10 material, and the gate plate 2 is brushed on the surface of the gate plate casting by Camrock adhesive and put into a metal mold EPDM rubber heated to 130°C and pressurized to 100MPa by a press is used for die-casting in a metal mold, so that the outer surface of the gate 2 casting is covered with a layer of rubber material layer 4, and the lower rubber material layer of the gate 2 Three rubber seals 8, 9, 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com